Dual temperature heat pump system

a heat pump and dual-temperature technology, applied in the field of electric heat pump systems, can solve the problems of complex algorithms, limited scope of heat generation to minimise cost over daily or longer periods, complex integration of variable load regulation and algorithms that attempt to minimise temperature differences, etc., to improve system flexibility, improve performance, and expand the range of heat demand and heat output of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

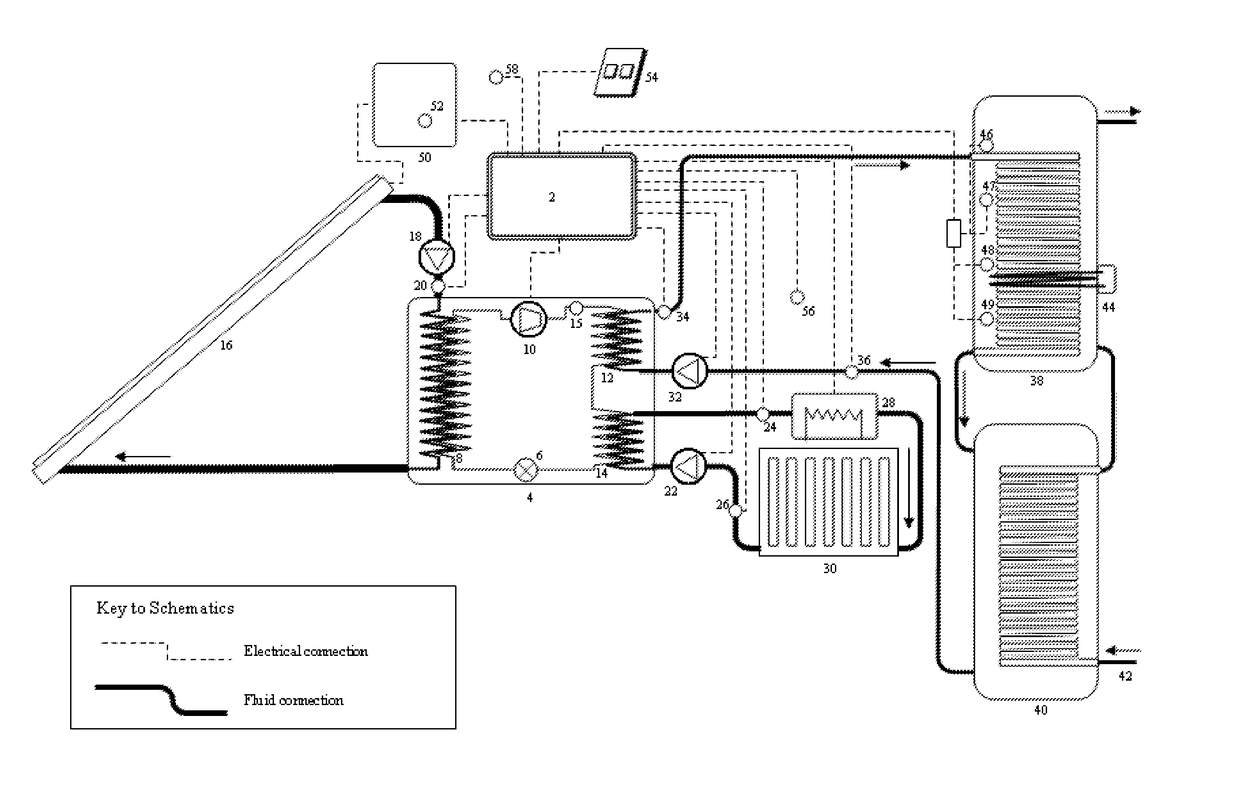

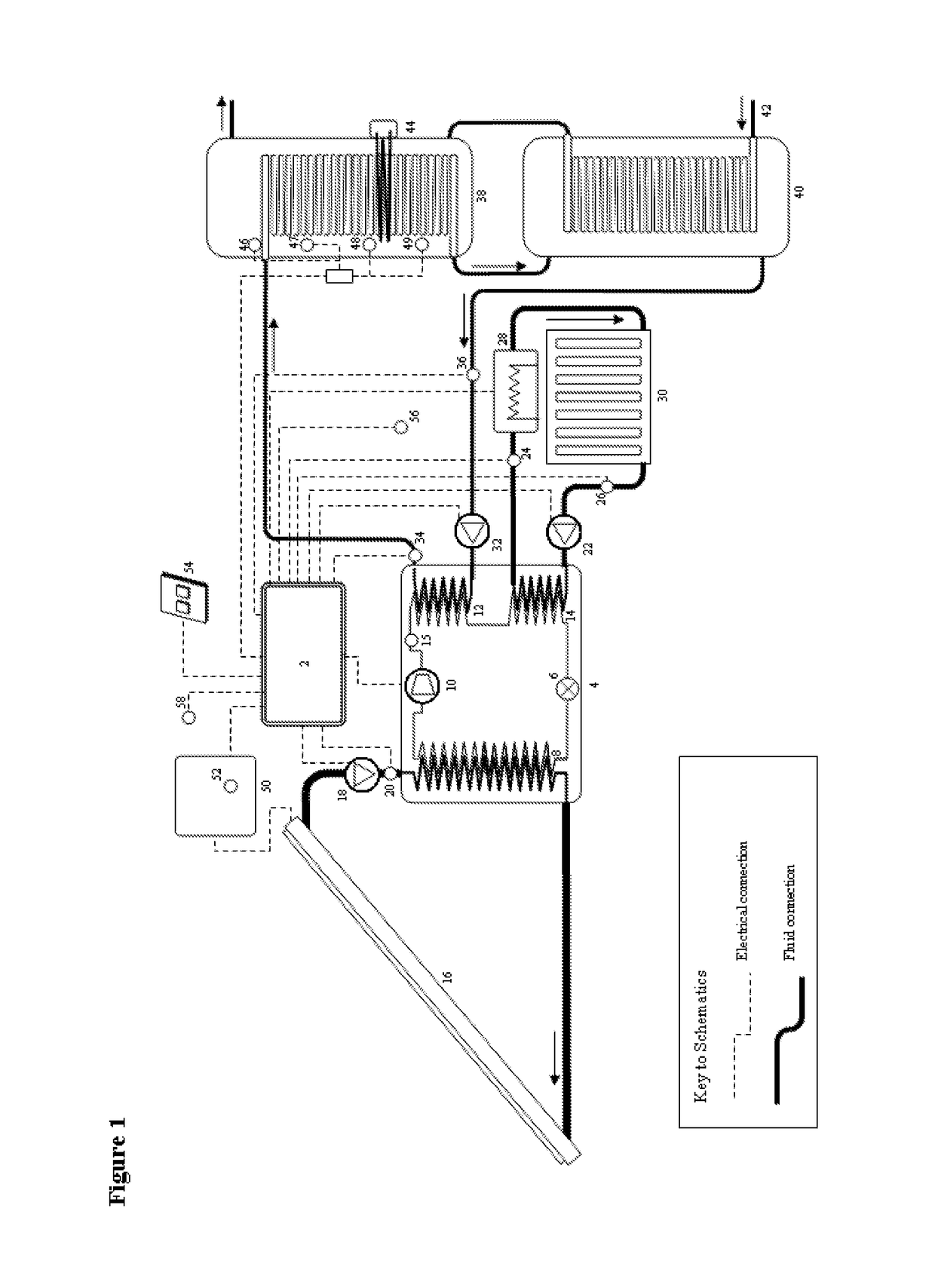

[0073]In exemplary embodiments of the present, FIG. 1, a system controller 2 (herein termed “the controller”) regulates a heat pump 4 which comprises a vapour-compression cycle for transferring heat from a heat source to a heat load.

[0074]In general, an aspect of the invention is a heating system for performing heating operations (and potentially also cooling operations) of a heated space. In exemplary embodiments, the heating system includes a heat pump and two heat output circuits in fluid communication with the heat pump for the flow of the refrigerant, the two heat output circuits comprising a major fluid circuit and a minor fluid circuit for performing different heating operations. The system further includes a power source having a variable cost. A controller is configured to control the heat pump and regulate flow of the major and minor fluid circuits to perform the heating operations. The controller is configured to determine a variable cost of electricity of the power sourc...

second embodiment

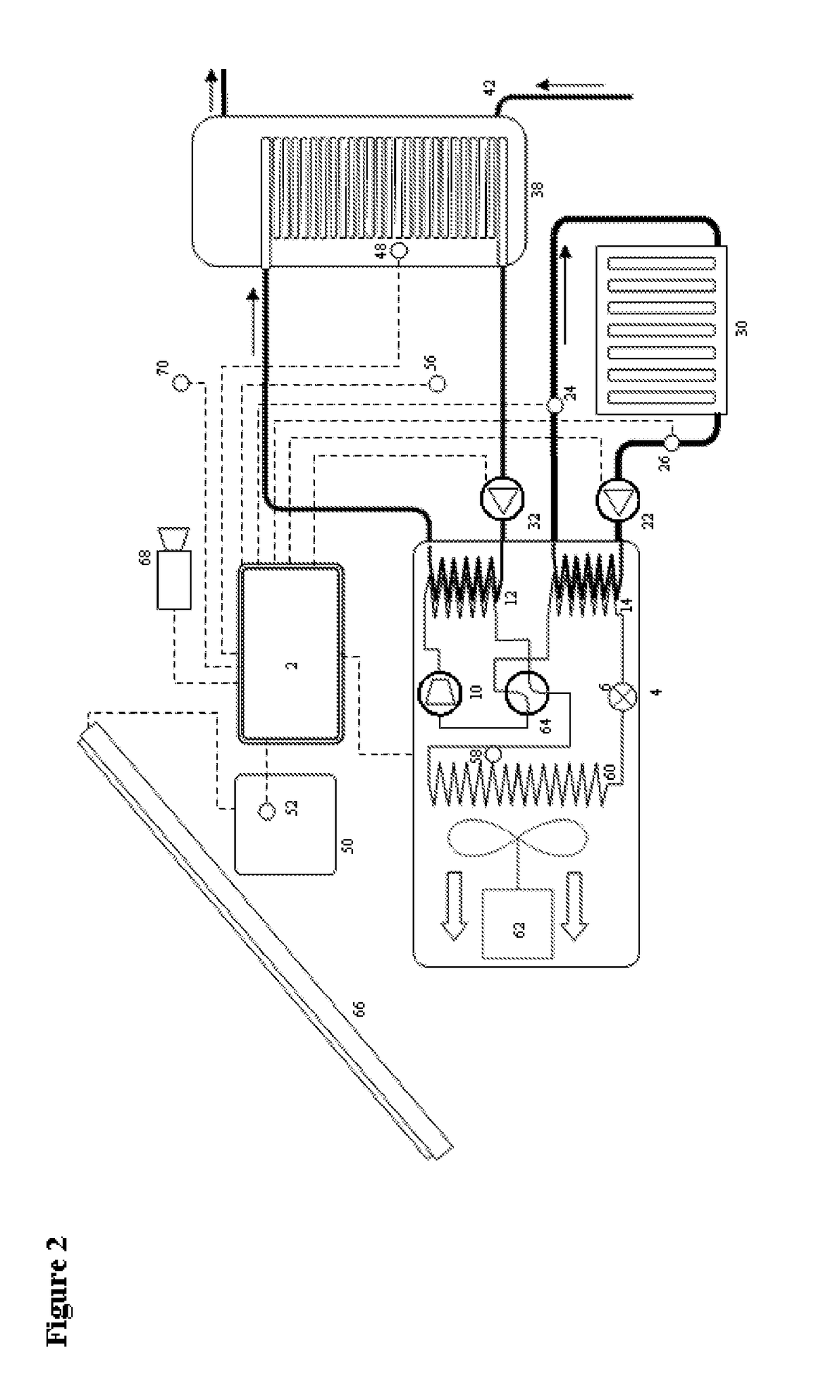

[0138]In a second embodiment of the invention, FIG. 2, the heat pump 4 includes a motorized electric fan 62 which is arranged to propel air through a finned-coil evaporator 60 in the manner of an “air-source heat pump”. In this embodiment the outdoor air temperature sensor is preferably mounted at the intake vent to the evaporator. The refrigeration cycle also contains a 4-way reversing valve 64 which is arranged in the configuration illustrated in EP0134015B1 (1984) and permits the source and major heat load circuits to be reversed such that heat can be extracted from the ‘load’ and rejected to the ‘source’ whilst the high temperature discharge heat of the refrigerant is still available to the minor circuit. This design of heat pump enables the major circuit to perform either heating or cooling functions, thus expanding the ability of the controller to minimise user discomfort. Furthermore, the combined operation of cooling the major circuit and heating the minor circuit yields a h...

third embodiment

[0147]In a third embodiment of the invention, FIG. 3, heat collectors, which may be plastic pipes that form a ground source heat exchange loop 72, are mounted in the ground in the manner of a “ground-source heat pump” system, and a circulating pump 18 transports heated coolant from the heat collectors to the heat pump evaporator 8. Ground source collectors provide a more stable temperature over daily and seasonal periods compared to air and solar-source collectors which assist the ability of the controller to predict the net cost of heat and devise more optimised heating plans. The disadvantages of ground source collectors are the high installation and maintenance costs compared to other heat sources and the relatively low source temperatures which are available during the summer.

[0148]The controller monitors the AC power output of a wind turbine generator 74 with a current transformer used as the electric generator power output sensor 52. The measured AC power is connected to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com