Composites of porous nano-featured silicon materials and carbon materials

a technology of porous nano-featured silicon and carbon materials, which is applied in the direction of silicon compounds, cell components, electrochemical generators, etc., can solve the problems of low power performance and limited capacity of graphitic anodes, insufficient current lead acid automobile batteries for next-generation all-electric and hybrid electric vehicles, and fundamental limitations of materials, etc., to achieve high first cycle efficiency, optimize lithium storage and utilization properties, and high reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Etching of Al—Si Alloy to Yield Bulk Porous Silicon

[0382]Aluminum-silicon alloy was dispersed in water and mixed by overhead mixer. Hydrochloric acid was added the dispersion over time, generating heat and accomplishing the etching. To avoid boiling, the heat generated is removed from the reactor by adding water ice to the system. Other modes to remove heat, such as employing a heat exchanger of varying modes of other approaches can also be employed, as known in the art. After the etching reaction subsided, the solids were allowed to settle in the reaction tank, and excess water decanted. The wet cake was dried in an oven, for example at 130 C, to yield dried, porous silicon with nano-scaled features. Alternatively, additional drying at a higher temperature, for example 450 C under an inert environment such as nitrogen gas, is also employed to yield the final dried, porous silicon. Alternatively, additional drying at a higher temperature, for example 1050 C under an inert environmen...

example 2

Particle Size Reduction of Bulk Porous Silicon

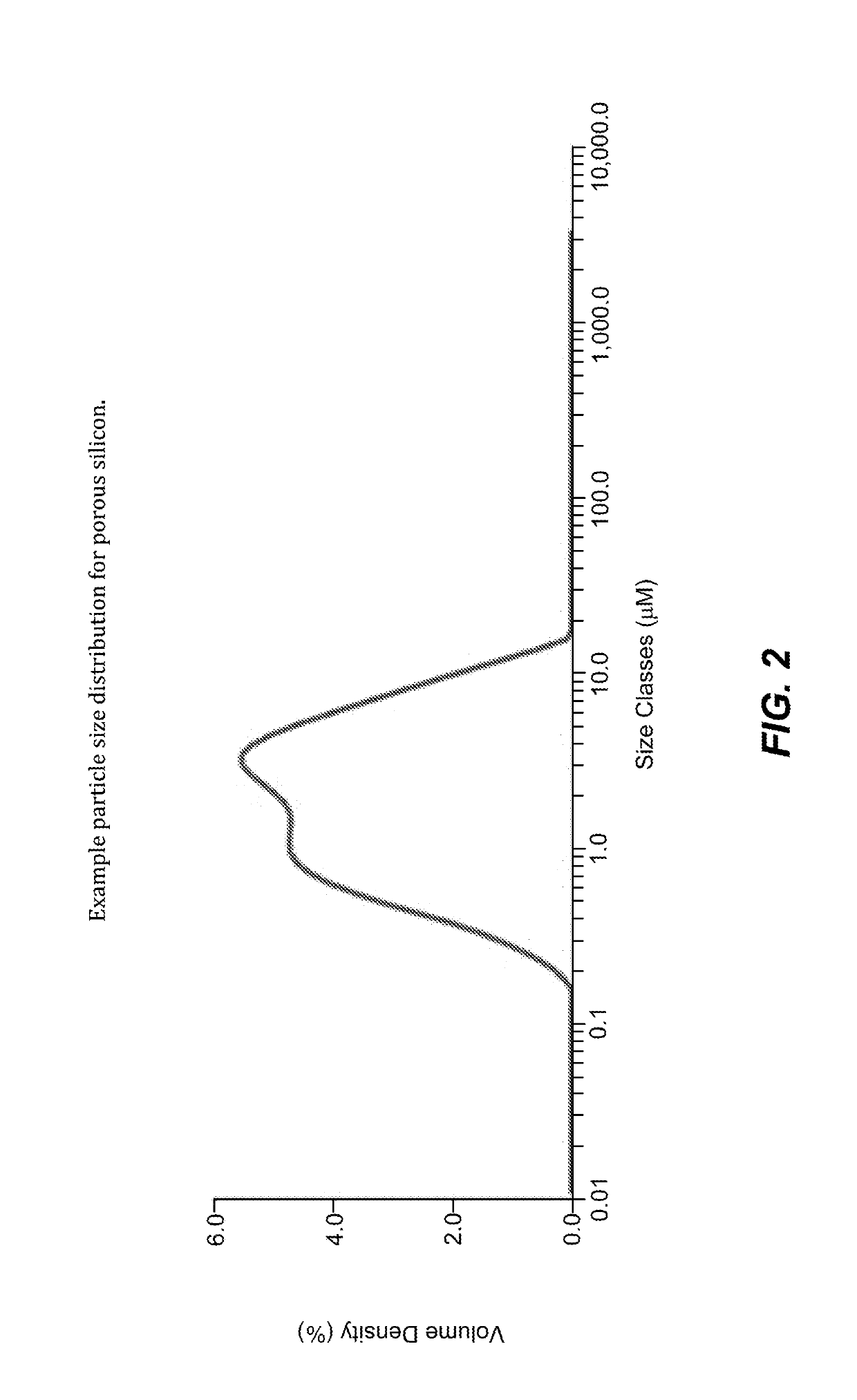

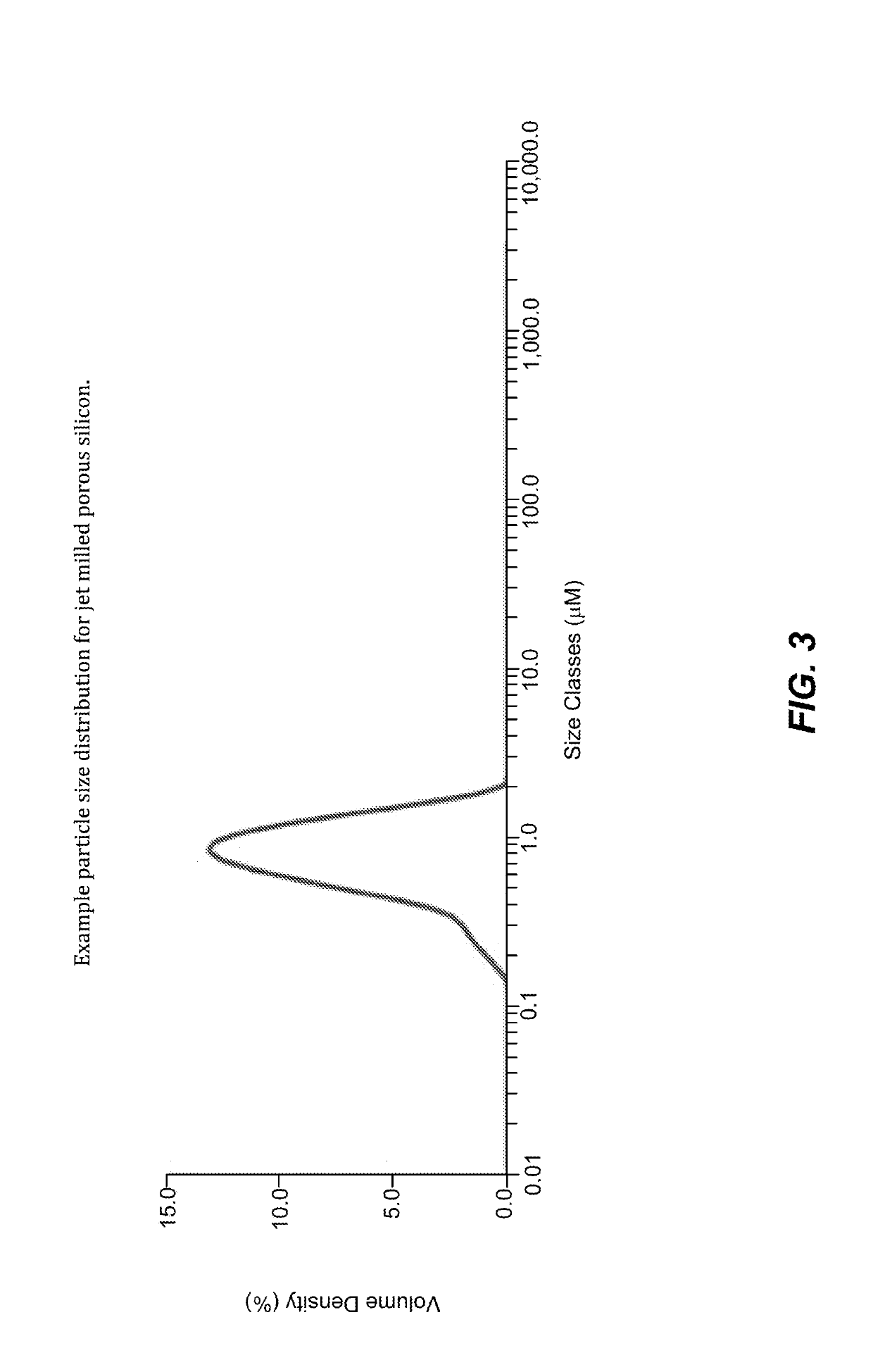

[0384]The bulk porous silicon from Example 1 can be size reduced, for example by methods known in the art such as grinding, ball milling, jet milling, water jet milling, and other approaches known in the art. In one embodiment, the porous silicon is particle sized reduced by jet milling. Example particle size distributions before and after jet milling are shown in FIG. 2 and FIG. 3, respectively. Before jet milling, the measured Dv0, Dv1, Dv5, Dv10, Dv20, Dv50, Dv80, Dv890, Dv95, Dv100 were 167 nm, 250 nm, 384 nm, 506 nm, 742 nm, 1.96 um, 4.63 um, 6.64 um, 12.0 um, and 16.2 um, respectively. This material was predominantly micron-sized, for example the Dv50 was 1.96 microns. After jet milling, the measured Dv0, Dv1, Dv5, Dv10, Dv20, Dv50, Dv80, Dv90, Dv99, and Dv100 were 146 nm, 194 nm, 290 nm, 388 nm, 505 nm, 766 nm, 1.10 um, 1.28 um, 1.65 um, and 1.87 um, respectively.

[0385]As can be seen, the porous silicon described herein was suffic...

example 3

Particle Size Reduction of Non-Porous Silicon

[0386]Employing the same jet milling strategy as for Example 2, an attempt was conducted to particle size reduce a commercially available non-porous silicon. Example particle size distributions before and after jet milling are shown in FIG. 4 and FIG. 5, respectively. Before jet milling, the measured Dv0, Dv1, Dv5, Dv10, Dv20, Dv50, Dv80, Dv890, Dv95, Dv100 were 147 nm, 247 nm, 546 nm, 702 nm, 942 nm, 1.66 um, 3.03 um, 4.64 um, 17.1 um, and 23.9 um, respectively. This material was predominantly micron-sized, for example the Dv50 was 1.66 microns. After jet milling, the measured Dv0, Dv1, Dv5, Dv10, Dv20, Dv50, Dv80, Dv90, Dv99, and Dv100 were 147 nm, 245 nm, 525 nm, 685 nm, 924 nm, 1.62 nm, 2.79 um, 3.79 um, 12.5 um, and 18.6 um, respectively. As can be seen, the non-porous silicon was non-friable. There was no appreciable particle size reduction upon jet milling the jet milled non-porous silicon remained micron-sized, specifically, the D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com