Iron-copper alloy having high thermal conductivity and method for manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0065]A ceramic melting furnace containing magnesium as a main component was prepared as a high-frequency inductively heated melting furnace. Thereafter, a porous impurity absorption layer was formed on an inner wall surface and a bottom surface of the prepared melting furnace. The porous impurity absorption layer was formed by coating an absorption layer composition to a thickness of approximately 1 mm, the composition prepared by mixing 65 wt. % of an impurity absorbent, 15 wt. % of a resin, and 30 wt. % of a solvent, based on the total weight of the composition, and then heating at a temperature of approximately 1,150° C. for firing. Here, zirconium silicate (ZrSiO4) and Al powder were used as the impurity absorbent, a butadiene-styrene-alkyl methacrylate copolymer was used as the resin, and isopropyl alcohol was used as the solvent.

[0066]Iron (pure iron having purity of approximately 99.9 wt. %) and electrolytic copper having purity of approximately 99.9 wt. %) were added to the...

examples 2 and 3

[0067]Iron-copper alloy ingots were prepared in substantially the same manner as in Example 1, except that amounts of iron additionally added during dissolution were changed for the purpose of making final alloy compositions (atomic percentages of iron and copper) differ from the alloy composition of Example 1.

examples 4-6

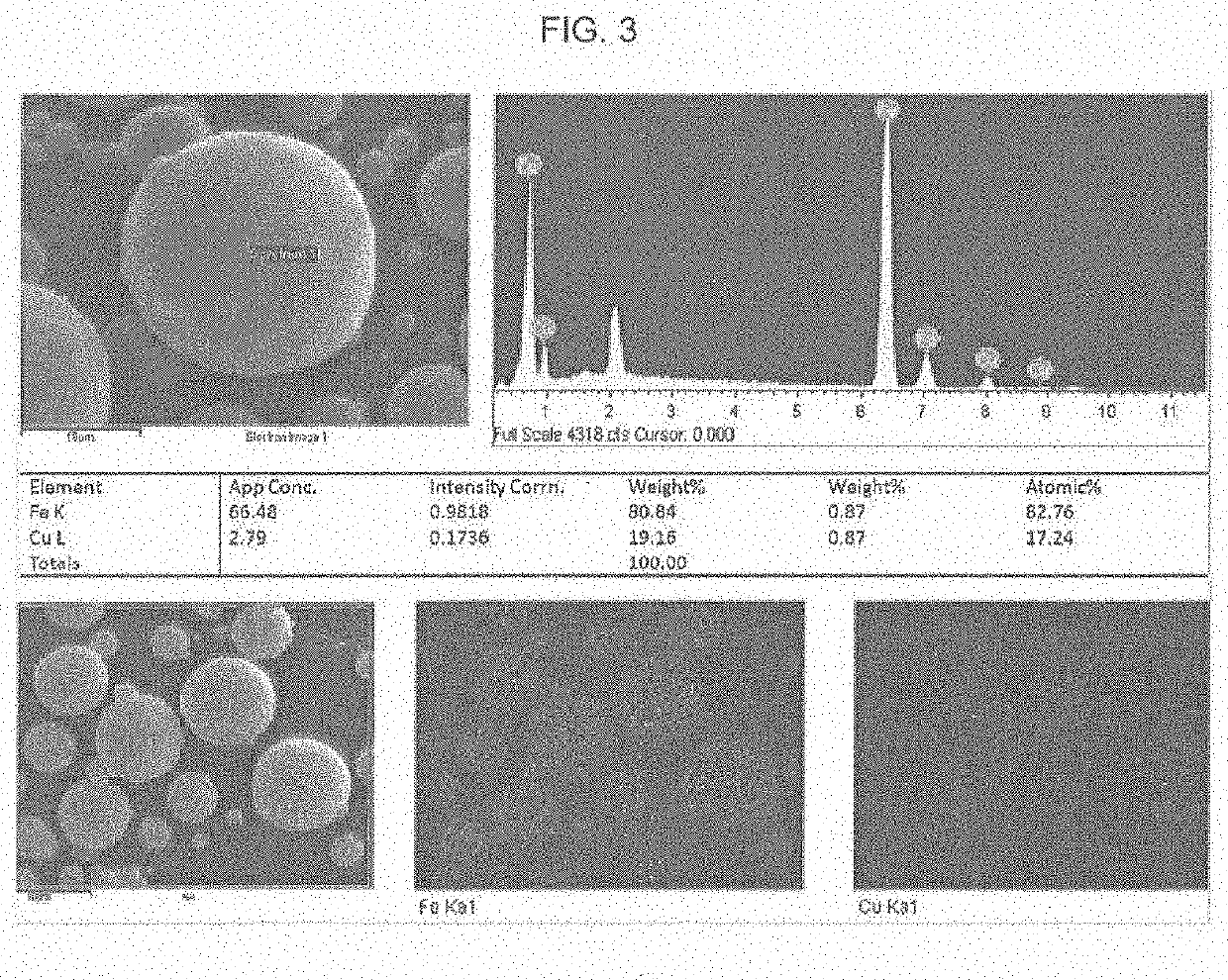

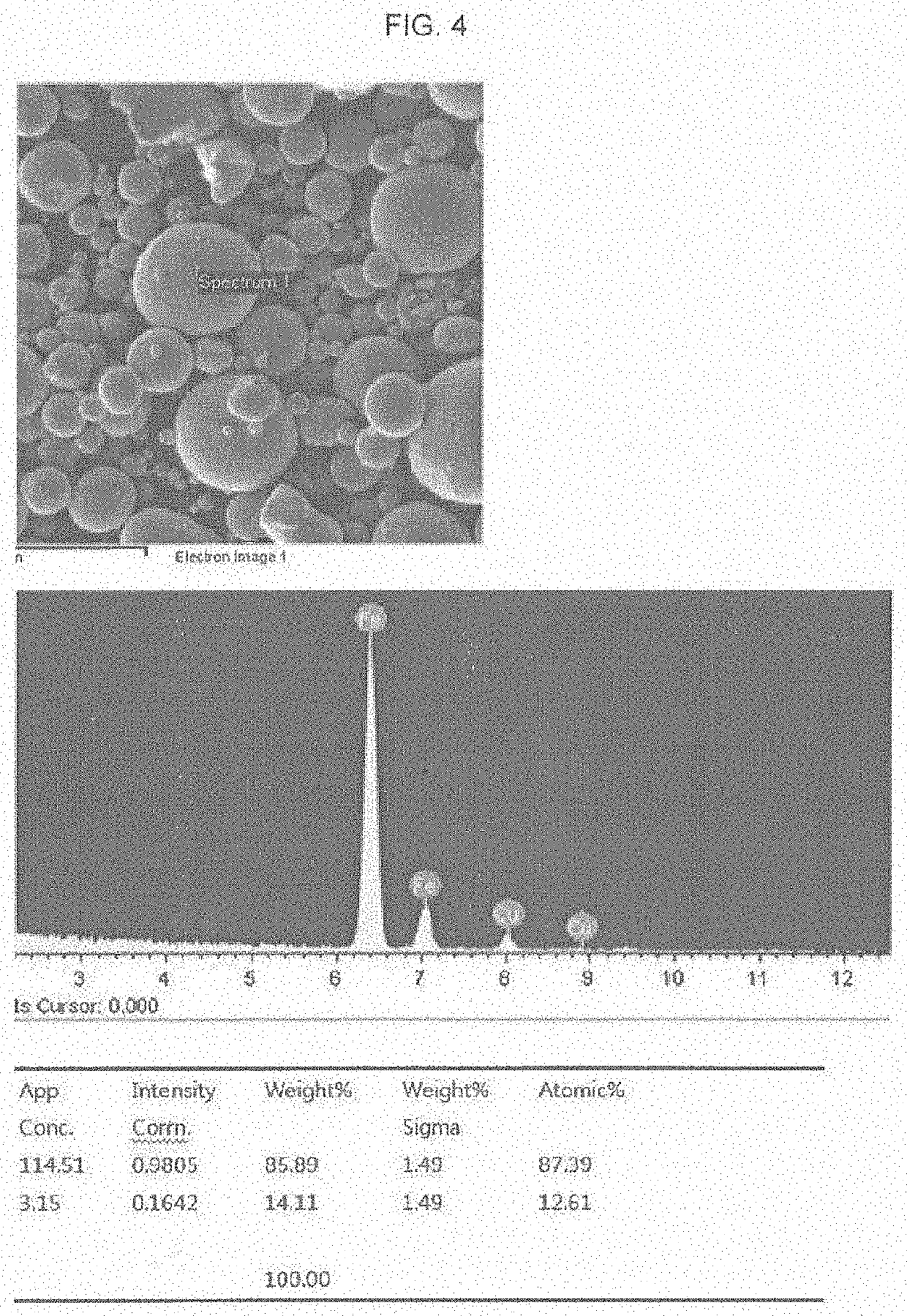

[0080]Iron-copper alloy ingots were prepared in substantially the same manner as in Example 1, except that amounts of iron additionally added during to dissolution were changed for the purpose of making final alloy compositions (atomic percentages of iron and copper) differ from the alloy composition of Example 1. In addition, in Examples 4-6, the iron-copper alloy ingots obtained through casting were granulated in the following manner to prepare powdered iron-copper alloy particles.

[0081]First, iron-copper alloy ingots according to Examples 4-6, which were obtained through casting, were placed in a high-frequency inductively heated melting furnace, and maximum power was applied thereto to perform remelting at a temperature of approximately 1,650° C. Here, the melting furnace was maintained in a vacuum state to prevent oxidation. Next, the remelted casting was granulated by injecting the same into an injection chamber using an injector. Here, the injection chamber was maintained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com