Laser texturing of ceramic-containing articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

hining Pins in a Si / SiC Wafer Chuck

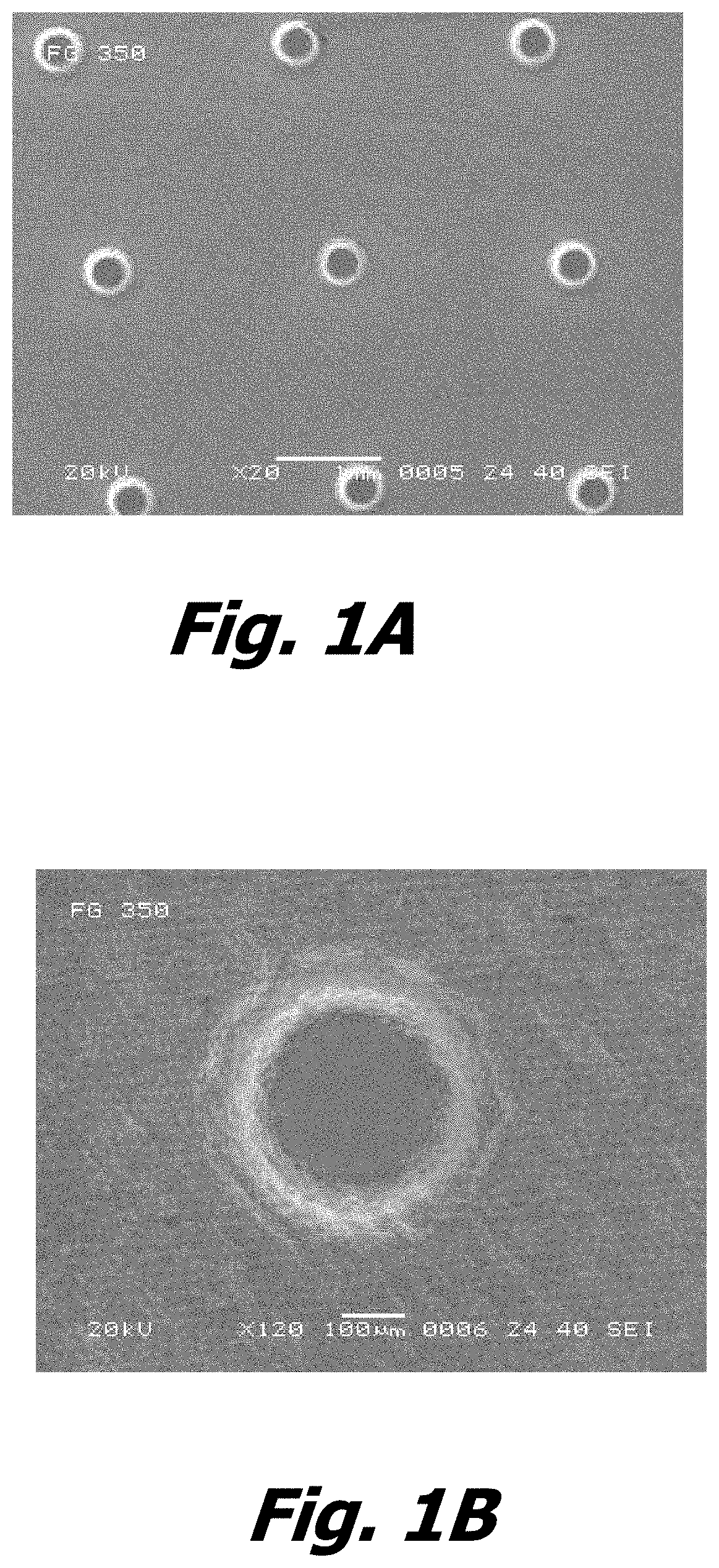

[0086]Refer now to FIGS. 1A and 1B, which are SEM photographs at different magnifications of pins in a Si / SiC wafer chuck that were laser machined according to the instant invention. The laser machining was performed by means of a cold ablation laser apparatus modified or supplemented with a means (e.g., a nozzle) to direct an inert gas (here, argon gas) onto the surface of the Si / SiC material to be machined in the vicinity, zone or region of the laser beam.

[0087]In addition to little-to-no surface modification of the machined surface of the Si / SiC material, the Ar-assisted cold-ablation laser machining provides;[0088]For more precise control of machined features[0089]Much less sub-surface damage[0090]Smoother surface finishes[0091]Much less roughness on feature edges[0092]No evidence of crack or void formation[0093]Avoidance of oxidation and reduced propensity for particle formation.

[0094]By “avoidance of oxidation”, the Applicant means that no ox...

example 2

n of Laser Drilled Holes in Si / SiC

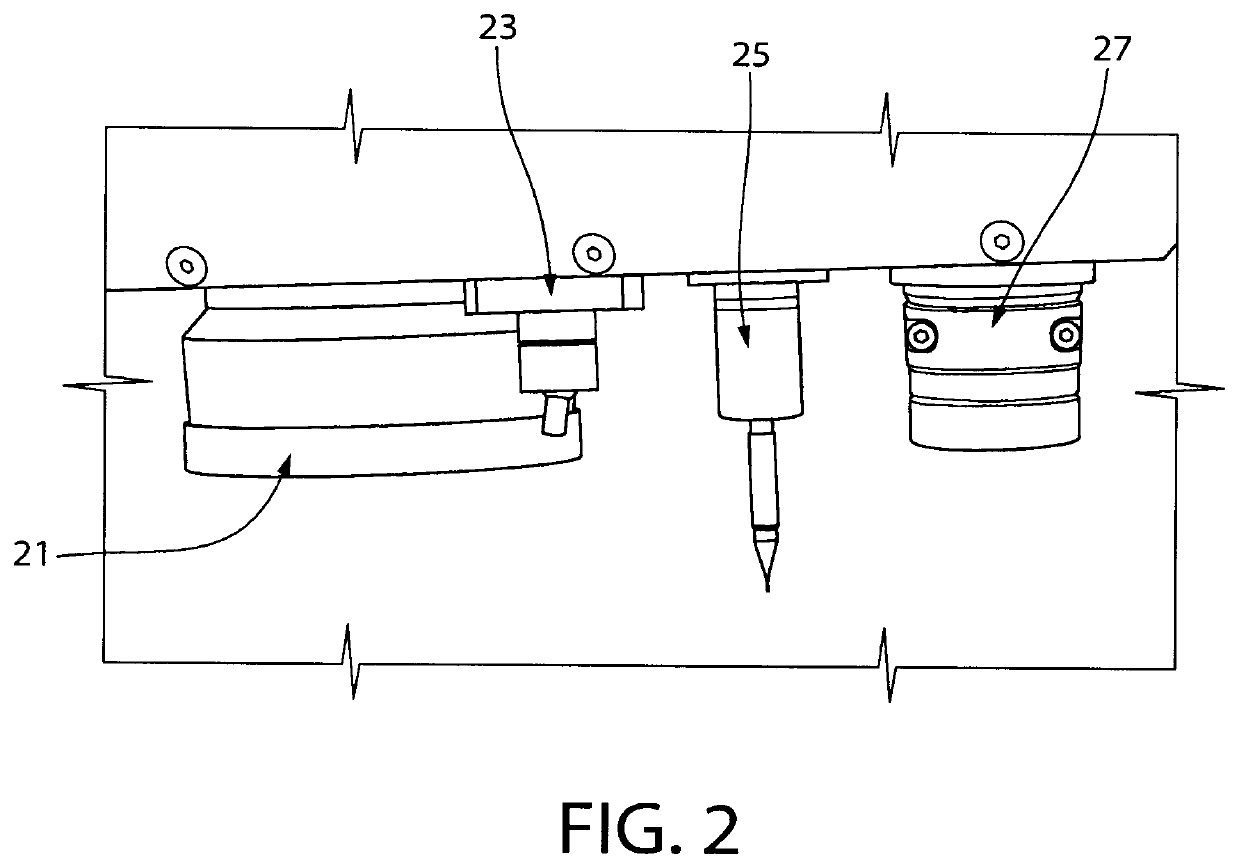

[0095]This example shows the effect of adding an inert gas “assist” to a cold ablation laser machining process.

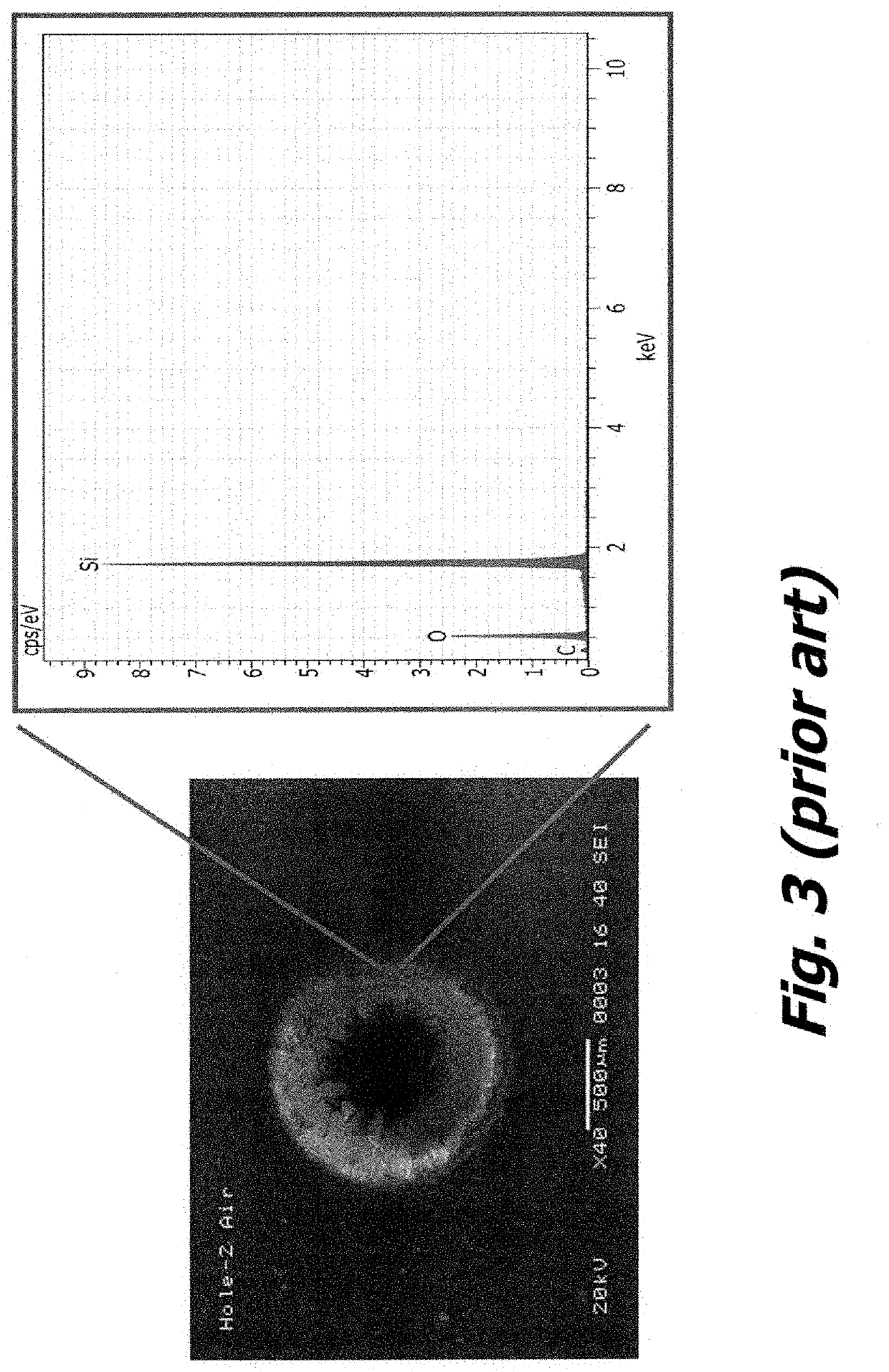

[0096]Here, the process is in drilling a hole in a Si / SiC composite material formed by a reaction-forming process. FIG. 3 shows the process being conducted in air. The left side of the figure is a SEM photo of the hole. The right side of the figure shows the elemental analysis of the edge of the hole according to energy dispersive analysis by x-ray (EDAX).

[0097]Similarly, FIG. 4 shows the process being conducted in flowing argon cover gas. The left side of the figure is a SEM photo of the hole. The right side of the figure shows the elemental analysis of the edge of the hole according to energy dispersive analysis by x-ray (EDAX). Comparing the ratio or relative sizes of the oxygen peak to the silicon peak in FIG. 3 versus FIG. 4, one can see that the oxygen peak is greatly reduced where the argon cover gas was used, indicating much less ox...

example 3

n of Pocket Cuts in Si / SiC

[0099]This example compares the quality of a “pocket cut” among the modified cold ablation laser machining technique of the instant invention, a prior art cold ablation laser machining process, and a prior art electrical discharge machining process. In each instance, the pocket cut was prepared on a sample of Si / SiC composite material produced by reaction bonding. A pocket cut may be prepared by providing an orthogonal prism of material such as a cube, and proceeding to shave off material on one side to a desired depth but leaving a region near the top surface intact, and then doing the same on an adjacent side surface, again leaving a region near the top surface undisturbed.

[0100]FIGS. 5A, 5B and 5C are SEM photographs at the same magnification of pocket cuts made into the Si / SiC samples by EDM, the prior art cold ablation laser in air, and the instant cold ablation laser machining under protective argon gas flow. The samples are oriented each the same way...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com