Process for preparing microcapsules

a microcapsule and slurry technology, applied in the direction of biocide, perfume formulation, detergent compounding agent, etc., can solve the problems of odoriferous compound loss relative to rapid, fragranced personal and household cleansers containing high levels of aggressive surfactant detergents, and difficult stability of microcapsules, so as to achieve good performance and not compromise the performance of microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

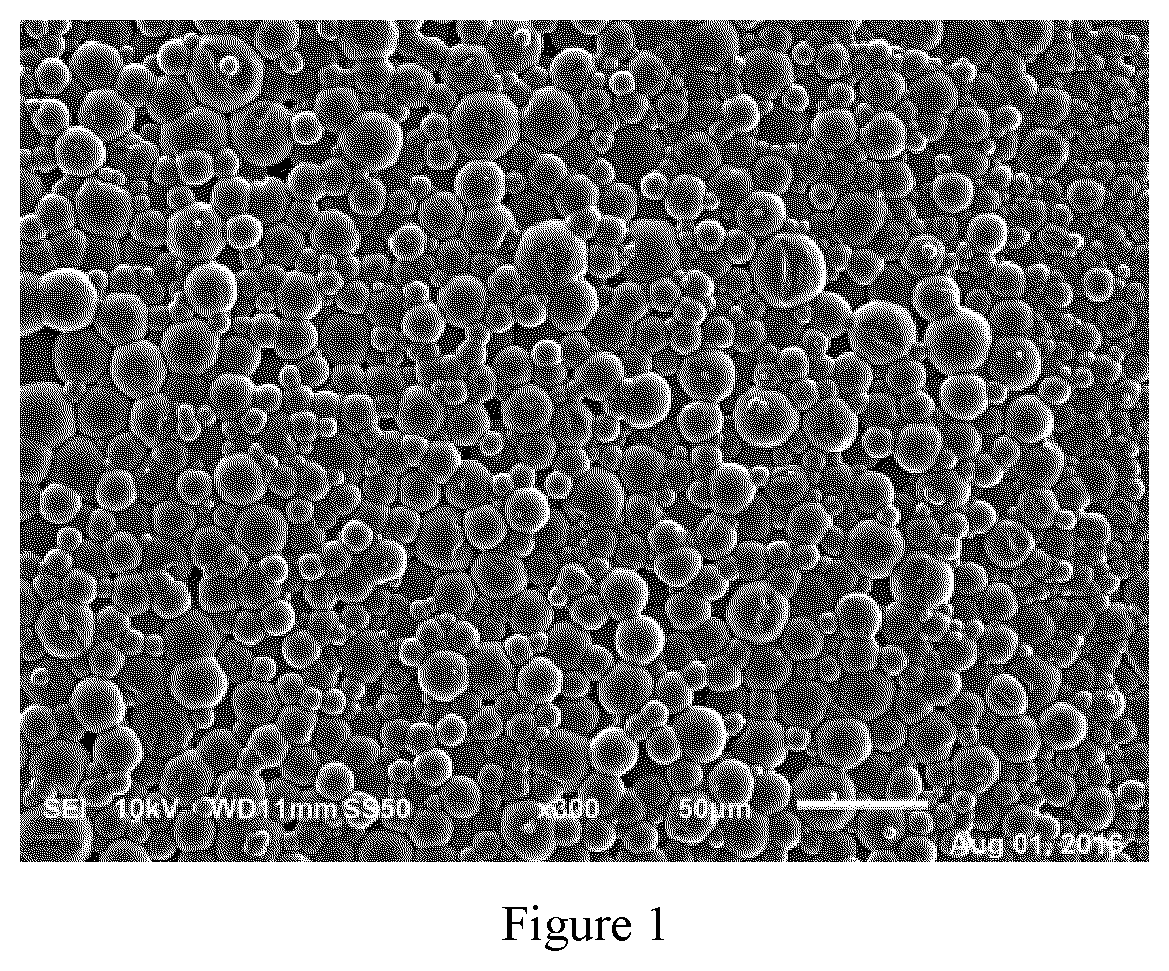

Microcapsules Preparation According to the Invention

Protocol

General Protocol of Lysine Triisocyanate Purification

[0240]Raw L-lysine triisocyanate (LTI—20 g—Watson International LTD) is weighed into a flask covered with the alumina foil and combined with methyl tert-butyl ether (150 mL). Activated carbon (4 grams) is added and the mixture is stirred for 30 minutes. The mixture is filtered and the filtrate is isolated and concentrated under reduced pressure in a rotavap to give amber oil.

General Protocol for Capsule Synthesis:

[0241]The purified LTI (light brown oil, 3 g) (with optionally Takenate® D110N) was dissolved in 30 g of a perfume oil (perfume oil A for capsules A-D or perfume oil B for capsules E—see respectively Table A and Table B). The oil phase was then added to an aqueous solution (37 g) comprising a stabilizer (1% gum arabic solution) and homogenized for 4 min using an Ultra-Turrax T25 disperser at 24000 rpm to form an O / W emulsion. The emulsion was pH adjusted to 10 us...

example 2

Stability of Microcapsules in a Shower Gel

[0245]Capsules slurry A (450 mg) or capsule slurry E (450 mg) has been introduced in a shower gel base (10 g) having the composition described in Table 6 (for Capsule slurry A) or Table 7 (for Capsule slurry E) leading to 1.4% of perfume oil in the sample.

TABLE 6Shower gel base composition AIngredientsQuantityDeionized water56.85EDETA B Powder0.05Glydant Plus Liquid0.21,2-Propylene Glycol2TEXAPON NSO IS27Citric Acid 20% aqueous solution1CREMOPHOR RH 401Perfume1Sodium Chloride0.7Sodium Benzoate0.25Sodium Salicylate0.25MERQUAT 5500.2Glucamate LT1.5TEGO BETAIN F 508

TABLE 7Shower gel base composition BIngredientsQuantityDeionized water49.35EDETA B Powder0.05CARBOPOL AQUA SF-1 POLYMER0.20Zetesol AO 328 U35.00SODIUM HYDROXIDE 20% aqueous solution1.00TEGO-BETAIN F 508.00KATHON CG0.10Citric Acid (40%)0.50

[0246]The amount of perfume having leaked out of the capsules was then measured by solvent extraction and GC-FID analysis (Table 8 and 9).

TABLE 8Le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com