Processing apparatus, measuring apparatus, and device manufacturing method

a technology of measuring apparatus and processing method, applied in the direction of fluid pressure control, testing/monitoring control system, instruments, etc., can solve the problems of inability to desirably transfer the mask pattern, the accuracy performance of the exposing apparatus deteriorates, and the throughput of the exposing apparatus is reduced, so as to eliminate the uneven internal temperature and the internal ambience stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0136]Preferred embodiments of the present invention will now be described in detail in accordance with the accompanying drawings.

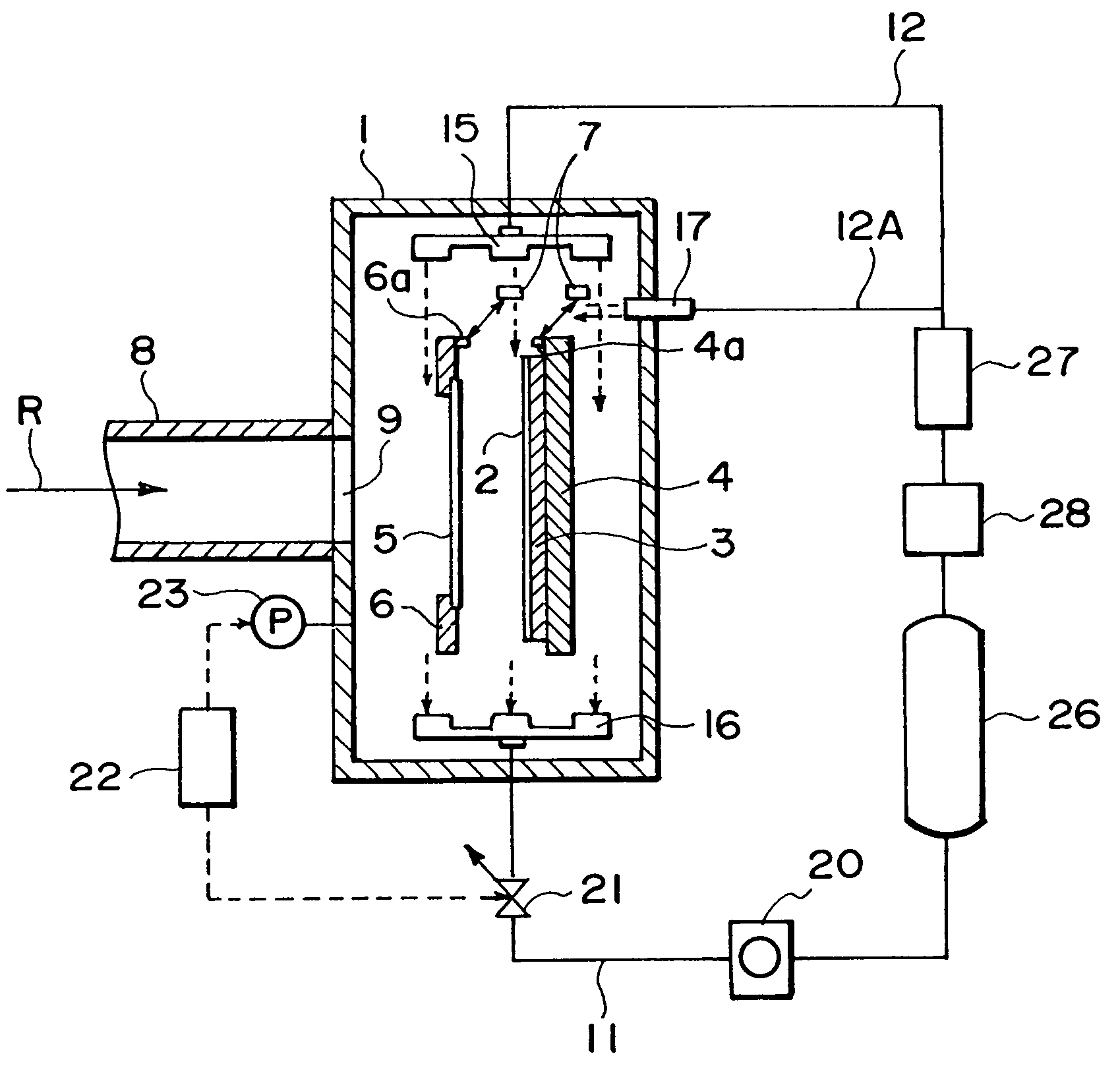

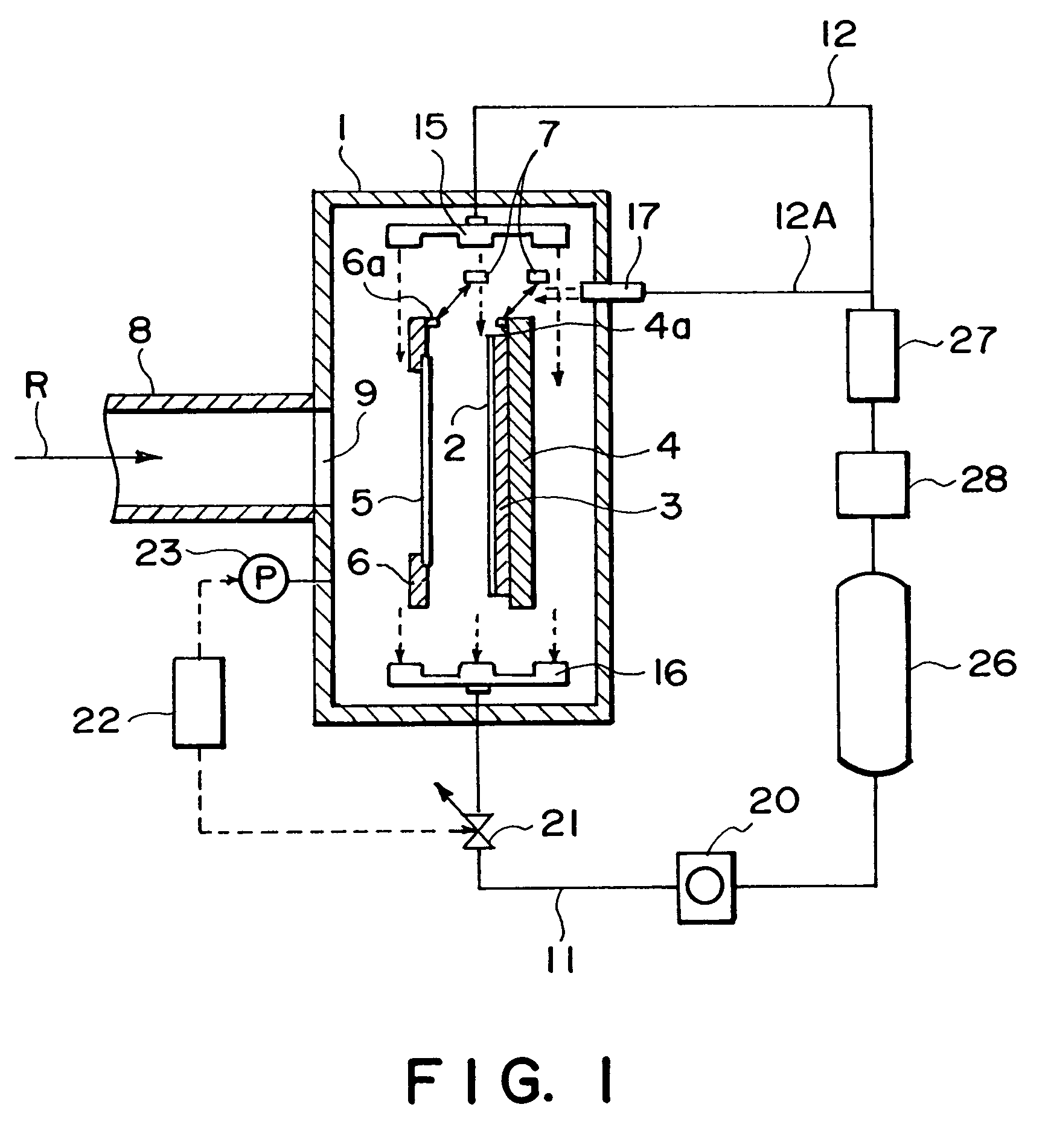

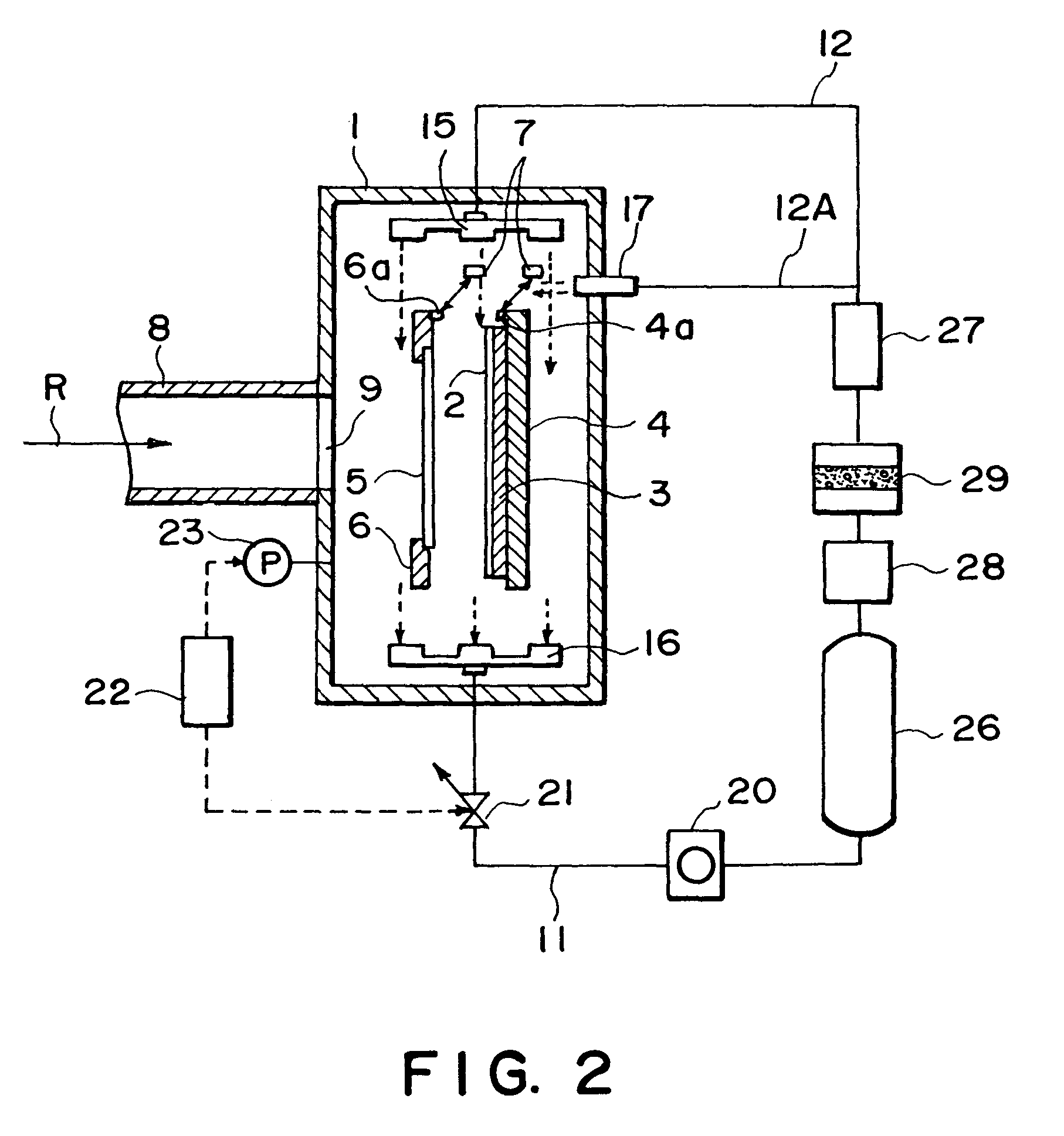

[0137]Referring to FIG. 1, an embodiment of the present invention will be described. FIG. 1 is a schematic view of an embodiment of the present invention in the form of a processing apparatus, that is, a semiconductor exposing apparatus.

[0138]A referential character 4 designates a positioning stage equipped with a suction chuck 3. The positioning stage 4 is placed in a sealed vacuum container 1 (hereinafter, “vacuum chamber”). The suction chuck 3 holds a piece of substrate 2 or wafer, with the use of suction. A referential character 6 designates a mask holding apparatus which holds a mask 5. Designated by a referential character 7 is a laser interferometry based measuring device, which is used to measure the position of the positioning stage 4. The positioning stage 4 which is holding the substrate 2 is accurately positioned based on the results of the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com