Optical displacement sensor using optical fiber, and external force detecting device

a technology of optical fiber and displacement sensor, applied in the direction of optical radiation measurement, photometry using electric radiation detector, instruments, etc., can solve the problems of high processing accuracy, increased electric power consumption, and increased cost as well as an increase in so as to reduce the number of components, reduce power consumption, and enhance the effect of displacement detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

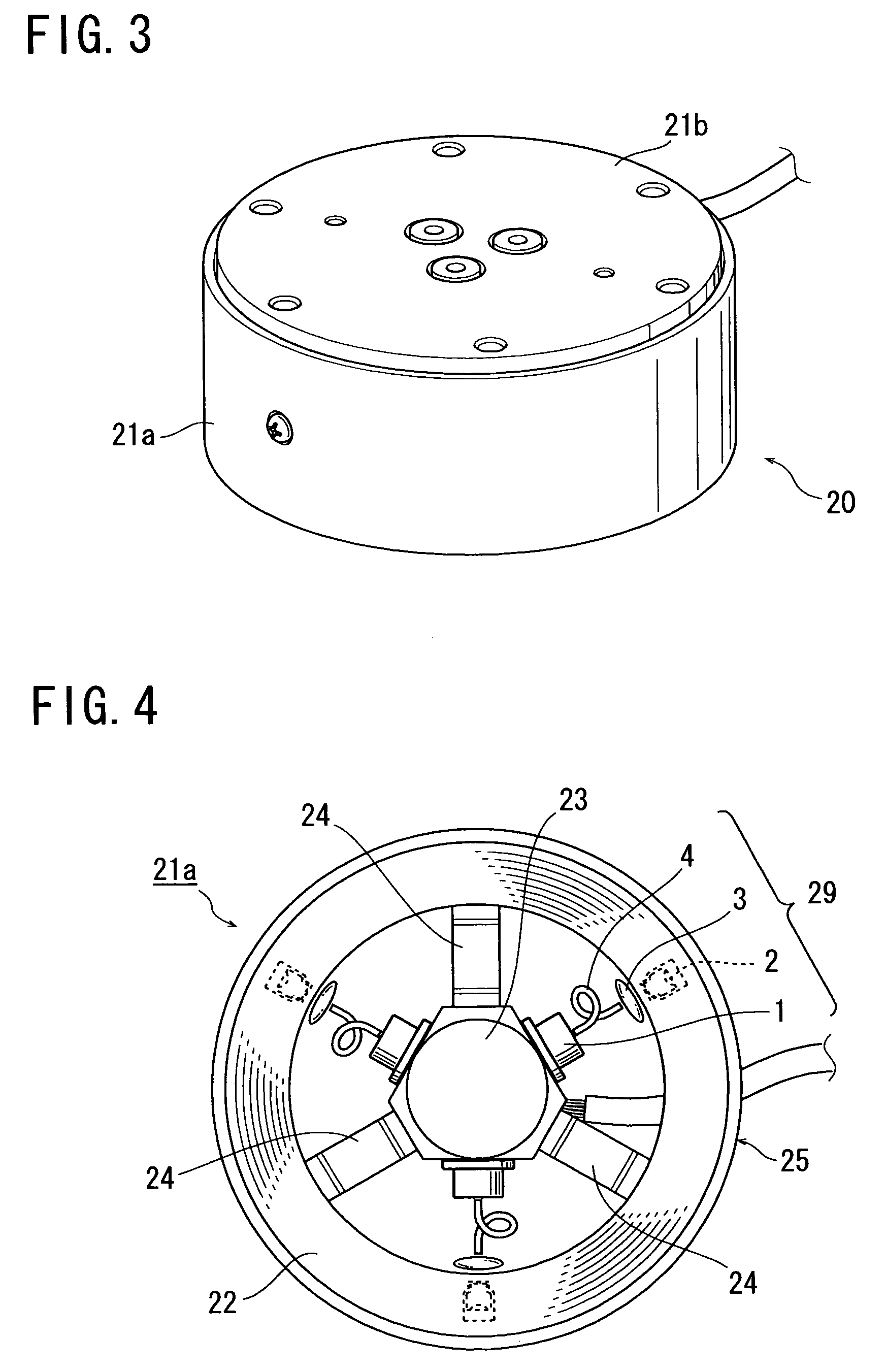

[0031]One embodiment of the present invention will hereinafter be described with reference FIGS. 3 to 7. Referring first to FIG. 3, a six-axis force sensor 20 is structurally composed of a cylindrical main body 21a, a disk-like top lid 21b, and a disk-like bottom lid (not seen). Referring now to FIG. 4, the main body 21a is constituted basically by a frame 25, which integrally includes: a cylindrical support section 22; an action section 23 disposed centrally inside the support section 22 and adapted to receive an external force; and three elastic spoke sections 24 crookedly structured so as to readily provide elastic deformation in all directions and supportably connecting the action section 23 to the support section 22. The frame 25 is made of a single piece of an aluminum alloy material and shaped by cutting and electric discharge machining. The support section 22 and the action section 23 are fixed respectively to two components to which a measurement force is applied, and when...

second embodiment

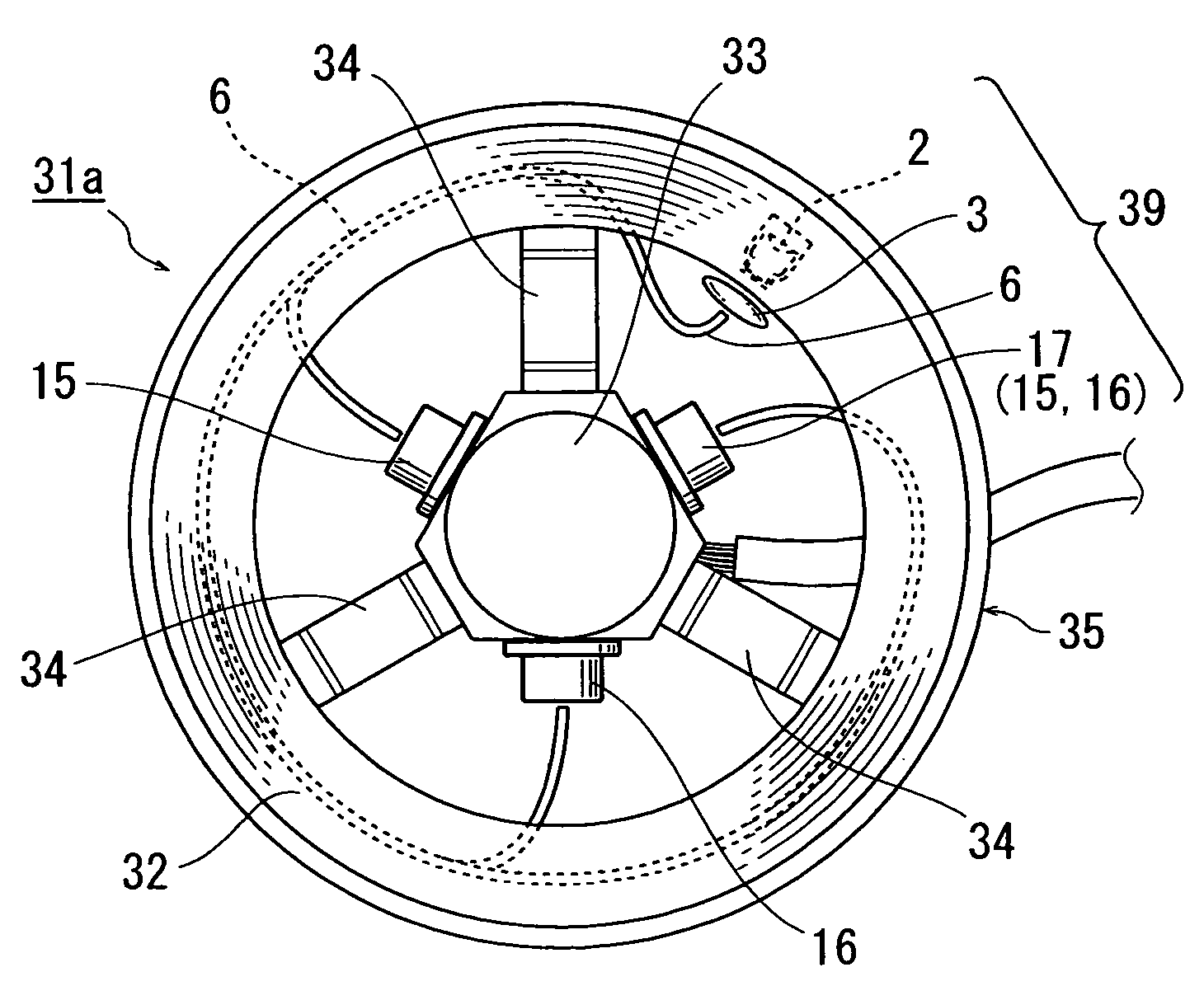

[0038]Another embodiment of the present invention will be described with reference to FIGS. 8 to 10. Referring first to FIG. 8, a six-axis force sensor 30 is structurally composed of a cylindrical main body 31a, a disk-like top lid 31b, and a disk-like bottom lid (not seen). Referring now to FIG. 9, the main body 31a is constituted basically by a frame 35, which integrally includes: a cylindrical support section 32; an action section 33 disposed centrally inside the support section 32 and adapted to receive an external force; and three elastic spoke sections 34 crookedly structured so as to readily provide elastic deformation in all directions and supportably connecting the action section 33 to the support section 32. The frame 35 is made of a single piece of an aluminum alloy material and shaped by cutting and electric discharge machining. The support section 32 and the action section 33 are fixed respectively to two components to which a measurement force is applied, and when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diffusing angle | aaaaa | aaaaa |

| diffusing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com