Praseodymium boride nano line, and its preparing method and use

A praseodymium hexaboride and nanowire technology is applied in the field of praseodymium hexaboride nanowires and their preparation, and achieves the effects of excellent field emission performance, easy operation and repetition, and simple test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Put the single crystal silicon wafer substrate with 1g of Pr powder (particle size about 0.1-0.5mm) into the middle of the quartz tube of the tube electric furnace, seal the quartz tube, and pre-evacuate the quartz tube at the same time, and then pass in H 2 / Ar(H 2 : Ar=0.1), its flow rate is 10 sccm;

[0031] (2) Heat the tube electric furnace to 970°C, and then feed BCl 3 , the flow rate is 100 sccm; at the same time, adjust the protective and reducing gas flow rate to 200 sccm; keep for 60 minutes;

[0032] (3) After the reaction, lower the temperature (flow rate is not limited) in the atmosphere of a mixture of protective gas and reducing gas (flow rate is not limited), until cooled to room temperature.

[0033] (4) Take out the monocrystalline silicon wafer substrate, soak it in distilled water for 4 hours, and then dry it in an oven. The obtained substance on the substrate is the praseodymium hexaboride nanowire.

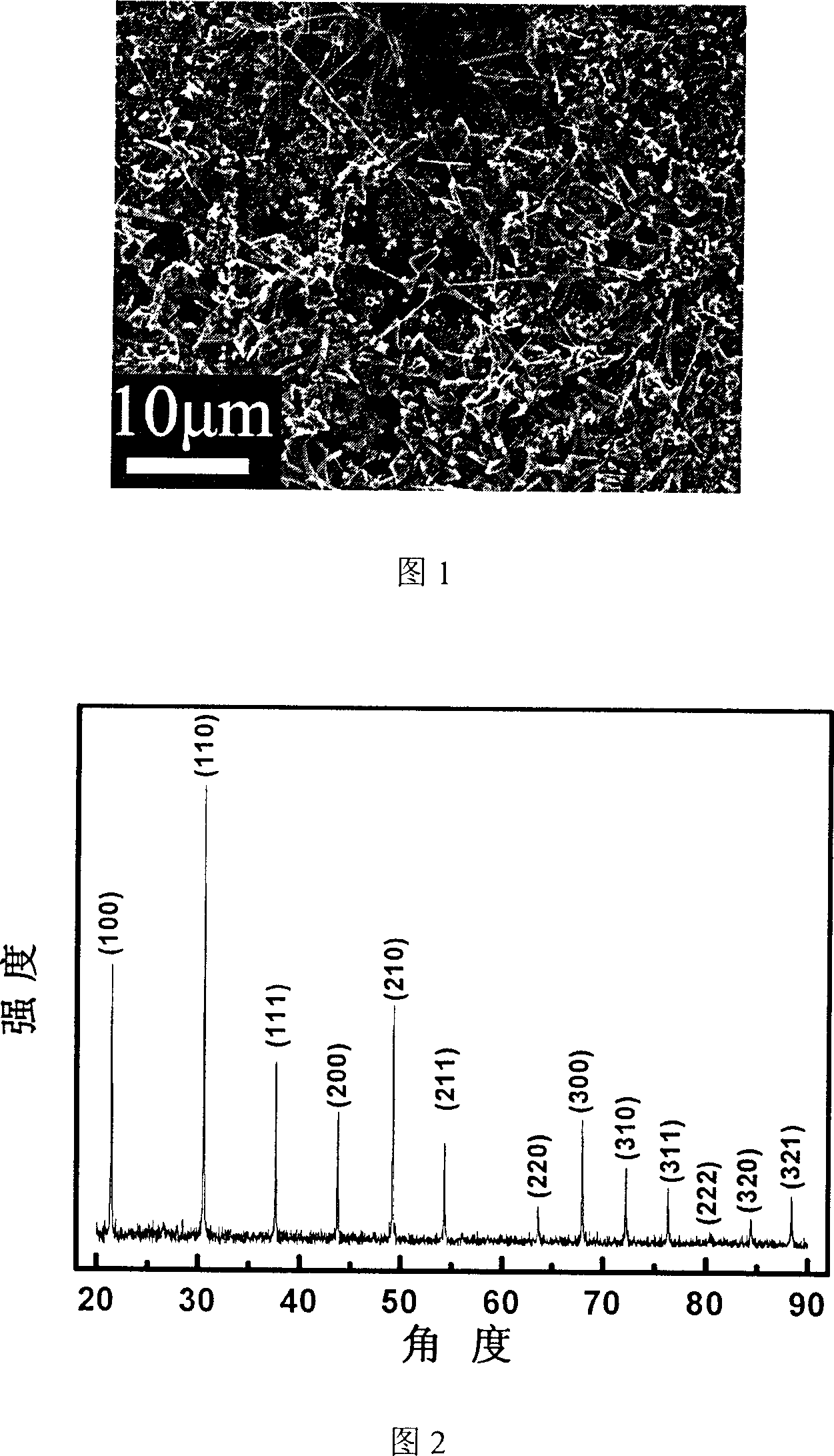

[0034] Fig. 1 is a SEM photograph of the...

Embodiment 2

[0036] (1) Put the monocrystalline silicon substrate with 0.5g of Pr powder (particle size about 0.1-0.5mm) into the middle of the quartz tube of the electric tube furnace, seal the quartz tube, and pre-evacuate the quartz tube at the same time, and then pass it into h 2 / Ar(H 2 : Ar=1), its flow velocity is 60 sccm;

[0037] (2) Heat the tube electric furnace to 1050°C, then feed BCl 3 , the flow rate is 60 sccm; at the same time adjust the protective and reducing gas flow rate to 120 sccm; keep for 30 minutes;

[0038] (3) After the reaction, lower the temperature (flow rate is not limited) in the atmosphere of a mixture of protective gas and reducing gas (flow rate is not limited), until cooled to room temperature.

[0039] (4) Take out the monocrystalline silicon wafer substrate, soak it in distilled water for 4 hours, and then dry it in an oven. The obtained substance on the substrate is the praseodymium hexaboride nanowire.

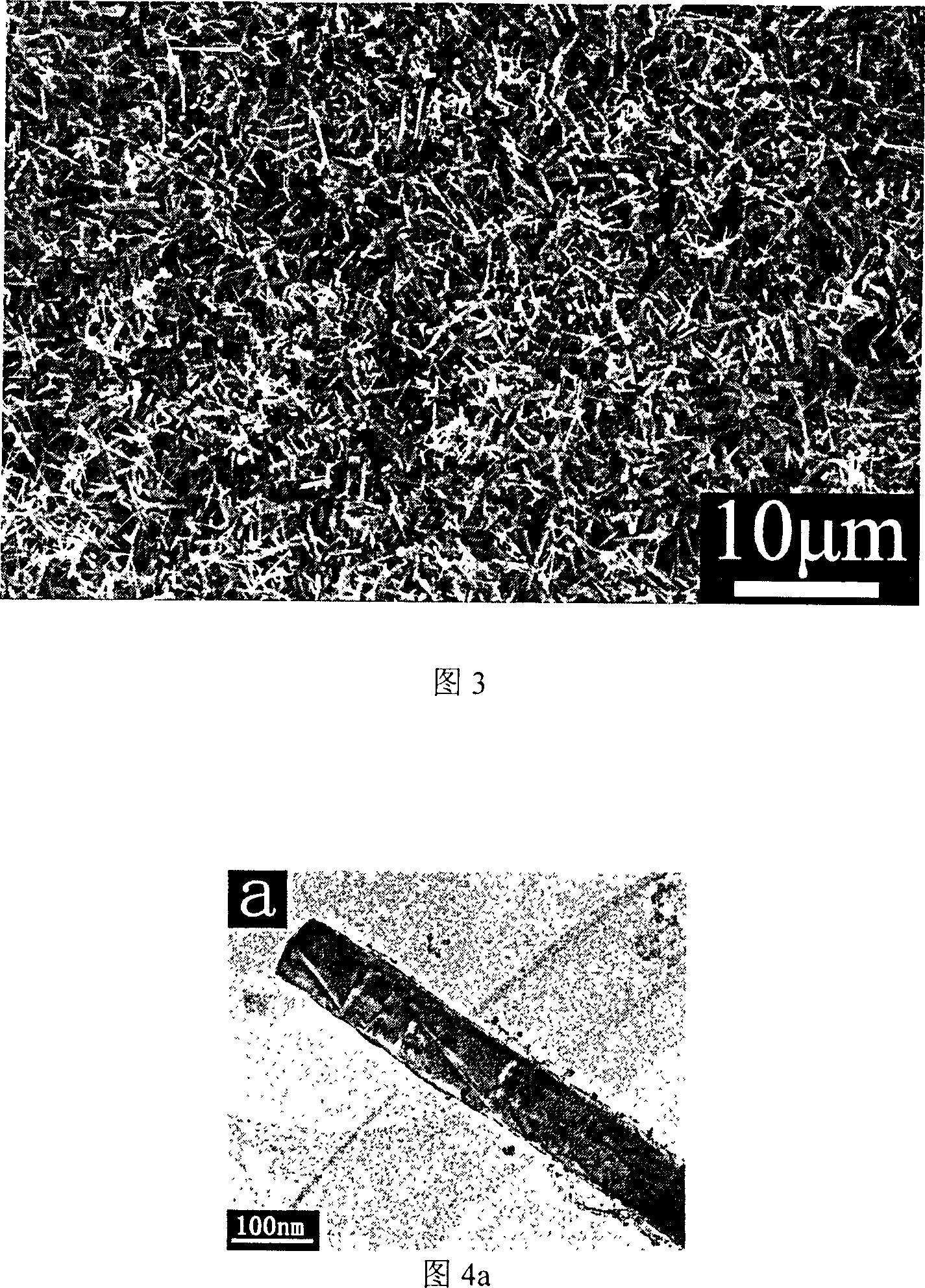

[0040] Fig. 2 is the X-ray diffraction (...

Embodiment 3

[0046] (1) Put the single crystal silicon wafer substrate with 0.1g of Pr powder (particle size about 0.1-0.5mm) into the middle of the quartz tube of the electric tube furnace, seal the quartz tube, and pre-evacuate the quartz tube at the same time, and then pass it into h 2 / Ar(H 2 : Ar=10), its flow rate is 100 sccm;

[0047] (2) Heat the tube electric furnace to 1150°C, and then feed BCl3 , the flow rate is 10 sccm; at the same time, adjust the protective and reducing gas flow rate to 20 sccm; keep it for 10 minutes;

[0048] (3) After the reaction, lower the temperature (flow rate is not limited) in the atmosphere of a mixture of protective gas and reducing gas (flow rate is not limited), until cooled to room temperature.

[0049] (4) Take out the monocrystalline silicon wafer substrate, soak it in distilled water for 4 hours, and then dry it in an oven.

[0050] Fig. 6 is the present embodiment sample PrB 6 The SEM photo of the nanowires, it can be seen from the figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com