Industrial manufacture method of single crystal phase mullite

An industrial manufacturing and mullite technology, which is applied in the industrial manufacturing field of single crystal phase mullite, can solve the problems of high content of harmful impurities, poor product performance and high production cost, and achieves simple production process, low production cost, and improved production efficiency. The effect of refractoriness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

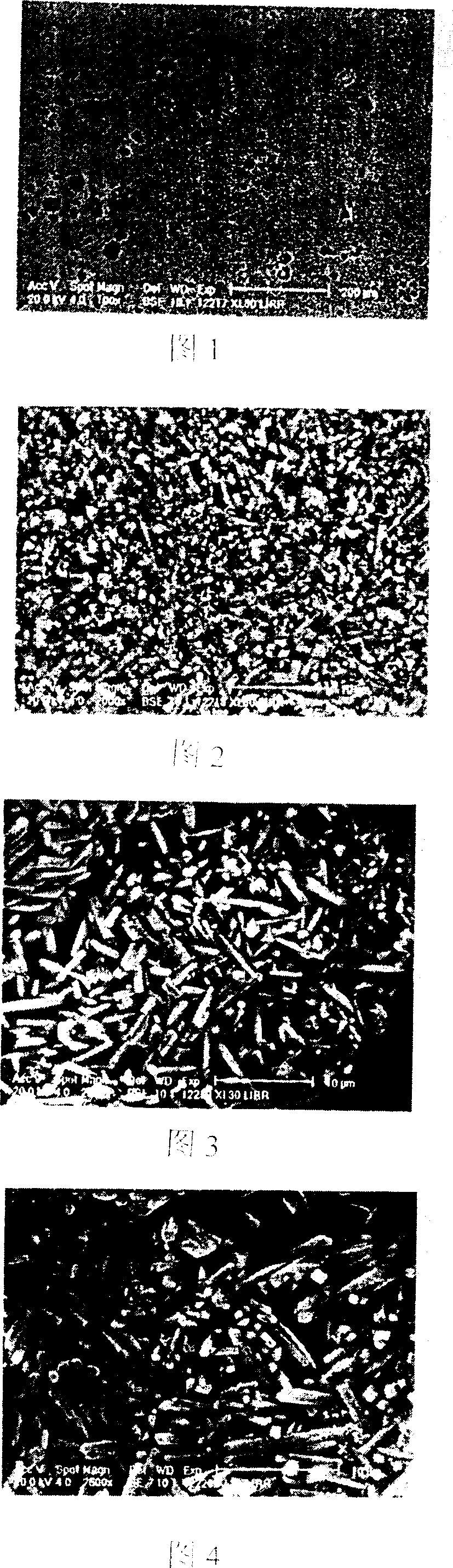

Embodiment 1

[0025] The industrial production method of single crystal phase mullite, comprising the following steps: a, crushing hard kaolin to 325 mesh; b, adding 0.02% mineralizer and 8% potassium feldspar of the weight of hard kaolin, mixing uniformly , the mineralizer is formed by mixing 10% potassium nitrate, 70% potassium carbonate and 20% potassium chlorate; c, dry molding; d, calcining at a high temperature of 1450° C. for 16 hours. The chemical composition and phase composition of the obtained single crystal phase mullite are shown in the following table:

[0026] chemical composition

Embodiment 2

[0028] The industrial manufacturing method of single crystal phase mullite comprises the following steps: a, crushing hard kaolin to 400 mesh; b, adding 0.03% mineralizer and 10% potassium feldspar by weight of hard kaolin, mixing uniformly, The mineralizer is formed by mixing 40% potassium nitrate, 50% potassium carbonate and 10% potassium chlorate; c, wet molding; d, calcining at a high temperature of 1550° C. for 16 hours. The chemical composition and phase composition of the obtained single crystal phase mullite are shown in the following table:

[0029] chemical composition

Embodiment 3

[0031] The industrial manufacturing method of single crystal phase mullite comprises the following steps: a, breaking hard kaolin to 350 mesh; b, adding 0.01% mineralizer and 9% potassium feldspar by weight of hard kaolin, mixing uniformly, The mineralizer is formed by mixing 30% potassium nitrate, 60% potassium carbonate and 10% potassium chlorate; c, dry forming; d, calcining at a high temperature of 1500° C. for 16 hours. The chemical composition and phase composition of the obtained single crystal phase mullite are shown in the following table:

[0032] chemical composition

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com