Permeation promoter for organic RE chemical heat treatment and its application

A technology of chemical heat treatment and permeation agent, which is applied in the direction of physical/chemical process catalyst, chemical/physical process, metal/metal oxide/metal hydroxide catalyst, etc., and can solve the problem that rare earth chlorides are prone to clogging droppers, etc. problems, to achieve the effect of overcoming the clogging of the dropper, increasing the cracking rate, and reducing the production of carbon black

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

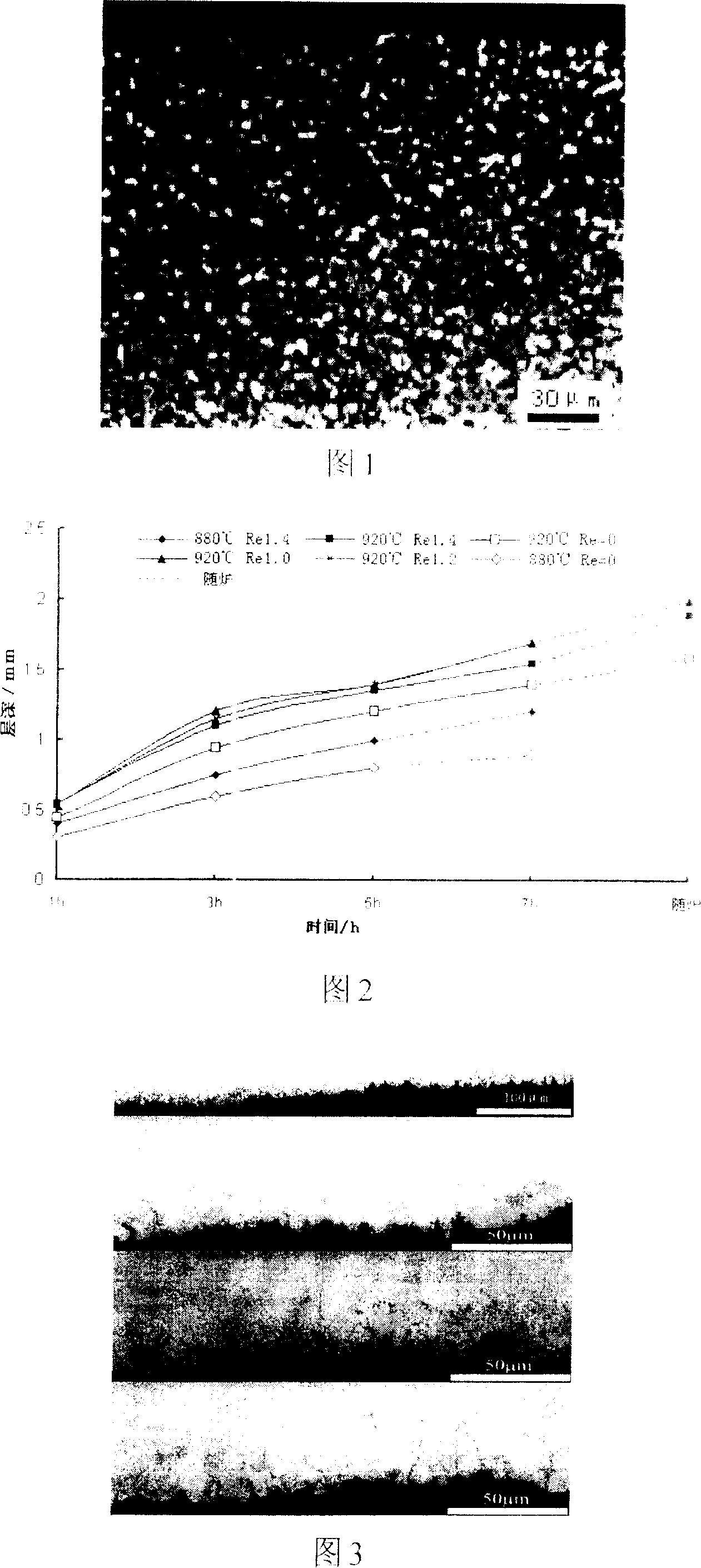

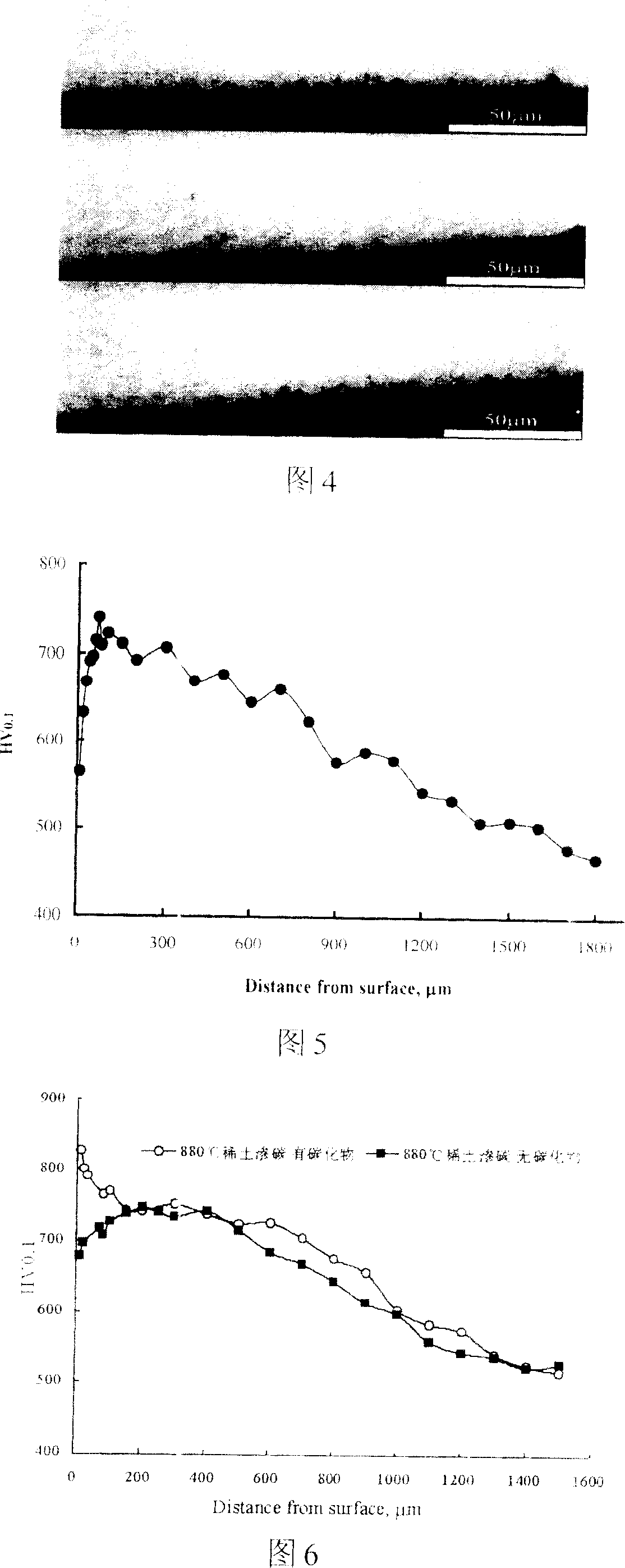

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment 1: The organic rare earth chemical heat treatment permeation agent of this embodiment is composed of the following components according to weight percentage: 8-12% rare earth elements, 5-8% tetrachloroethylene, 1-4% rare earth metallocene, isomeric acid and the balance of isomeric alcohols.

[0023] In this embodiment, the rare earth elements are mixed rare earth metals with La and Ce as the main body, simple La or simple Ce rare earth metals; the isomeric acids are isooctanoic acid and naphthenic acid; alcohol. The infiltrating agent is soluble in kerosene, benzene and toluene, and is used to prepare carburizing and carbonitriding infiltrating agents.

specific Embodiment approach 2

[0024] Specific implementation mode two: the present implementation mode realizes its object of the invention through the following technical solutions:

[0025] 1. Test conditions:

[0026] 1. 105KW well-type carburizing furnace, equipped with a microcomputer automatic control system manufactured by Beijing Huijietong Company;

[0027] 2. Main penetration agent: kerosene, carrier gas: methanol;

[0028] 3. Workpiece material: 20CrMnTi; the workpiece is a gear below M6;

[0029] 4. Organic rare earth permeation agent: YF-I type, isooctanoic acid, naphthenic acid, and isooctyl alcohol are prepared as an extraction agent in a weight ratio of 2:1:1. After ammoniation at 70% of the acidity value, use super-concentration The organic rare earth solution is prepared by extraction technology, adding 5-8% tetrachlorethylene and 1-4% peracene rare earth to each liter of organic rare earth solution, which contains 8-12% pure rare earth, and mixes it with kerosene in different proportio...

specific Embodiment approach 3

[0035] Specific embodiment three: The organic rare earth chemical heat treatment permeation agent of this embodiment is composed of the following components according to weight percentage: 8-12% rare earth elements, 5-8% tetrachloroethylene, 1-4% rare earth metallocene, isobutyric acid Ammonium 20-30%, the balance of isomeric acid and isomeric alcohol.

[0036] In this embodiment, the rare earth elements are mixed rare earth metals with La and Ce as the main body, simple La or simple Ce rare earth metals; the isomeric acid is isooctanoic acid and naphthenic acid; the isomeric alcohol is isooctyl alcohol.

[0037] When organic rare earth chemical heat treatment infiltration catalyst is dissolved in different solvents (kerosene, ethyl acetate, acetone or isopropanol), it can be used for different purposes: carburizing, carbonitriding, nitriding, nitrocarburizing or multi-component Infiltration (Re, N, C, O, S, B).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com