Improving method for rigid chain liquid crystal polymer and flexible chain nylon compatibility

A technology of liquid crystal polymers and compatibility, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of difficulty in obtaining compatible composite materials, limited improvement of compatibility, and increased processing costs, and achieve durable Effects of chemical corrosion on physical and chemical properties, low thermal expansion coefficient, and reduction in processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

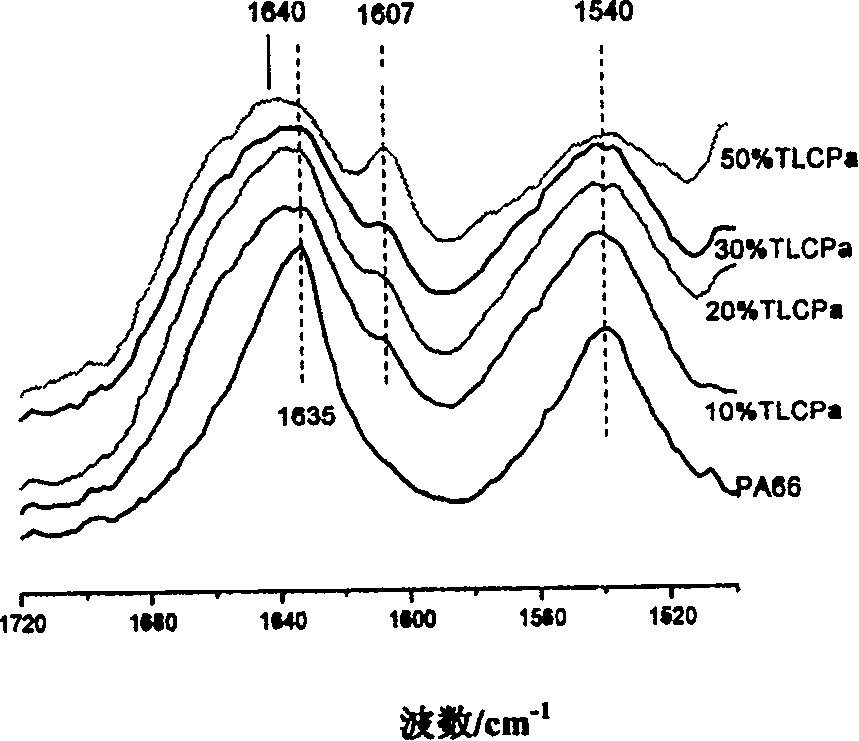

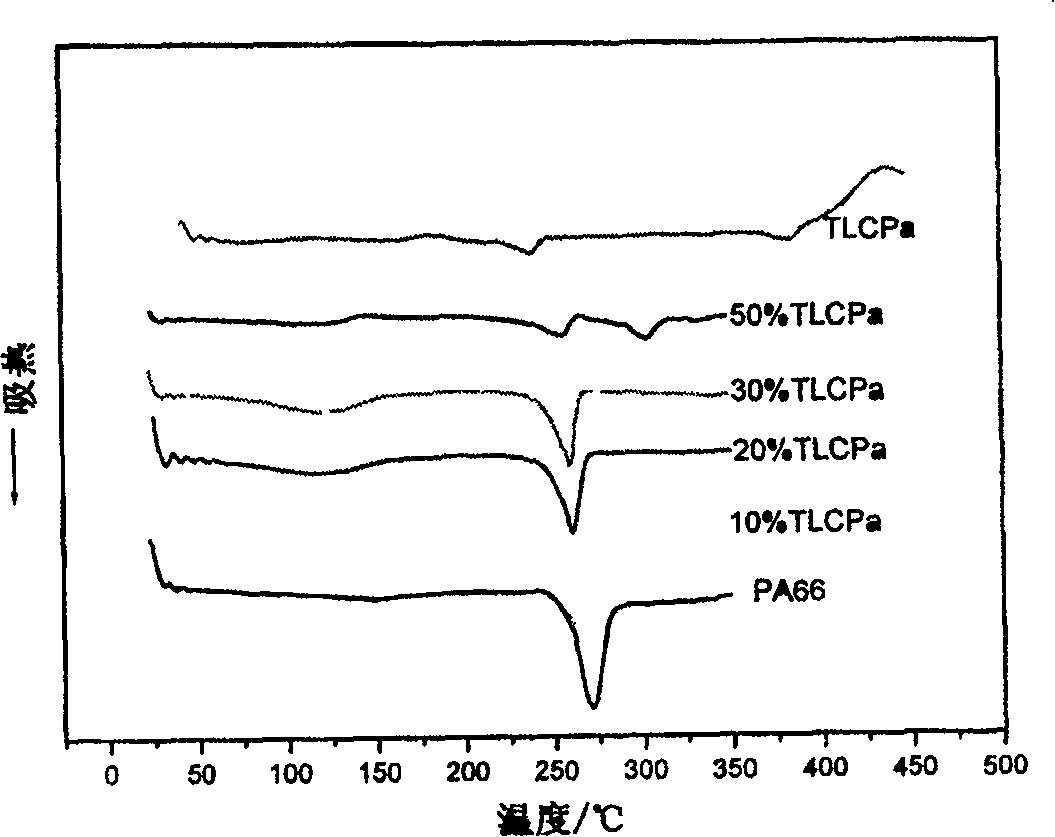

[0032] Example 1: Melt blending of thermotropic polyamide liquid crystal (a) (TLCPa) and nylon 66 (PA66)

[0033] Step (1): Synthesis of Polyamide Liquid Crystal Polymer

[0034] Take the strictly dried polyethylene glycol bis-4-carboxyphenyl ether (PEG 2 ) 29.82g, polyethylene glycol bis-4-carboxyphenyl ether (PEG 3 ) 33.62g, o-toluidine (OT) 36.56g, anhydrous lithium chloride (LiCl) 146.01g, refined triphenyl phosphite (TPP) 1335.95g, pyridine (PY) 345ml, N-methylpyrrolidone (NMP)689ml, of which PEG 2 、PEG 3 The ratio of the amount of the three monomers of , OT is 1 / 1 / 2, under the condition of nitrogen protection, under the temperature of 120 ℃, stir at a constant speed, and the copolymerization reaction is 2h;

[0035]Put the system after the copolymerization reaction into the constantly stirring methanol solvent to precipitate the copolymerization product evenly. After the precipitate is filtered with a vacuum filter, it is repeatedly washed and compacted with distille...

example 2

[0041] Example 2: Melt blending of thermotropic polyamide liquid crystal (a) and nylon 6

[0042] Step (1): Same as step 1 of Example 1;

[0043] Step (2): blending of polyamide liquid crystal polymer (a) and nylon 6

[0044] 1) Firstly, the polyamide liquid crystal polymer (a) is blended with nylon 6 at a mass ratio of 10%, 20%, 30%, 40%, and 50%, respectively, and then vacuum-dried at 80°C for 48h, and then the polyamide The liquid crystal polymer (a) is simply mechanically pre-mixed with nylon 6, so that the two are fully mixed and uniform;

[0045] 2) Add the mixture of the pre-mixed polyamide liquid crystal polymer (a) and nylon 6 into the extruder for melt blending, the number of revolutions per minute (rpm) of the rotor is 100, according to the principle of melting point matching, make it Melt blending with nylon 6, the melting temperature is 240°C, and the blending time is 15min.

[0046] After melt-blending the thermotropic polyamide liquid crystal (a) with nylon 6...

example 3

[0047] Example 3: Melt blending of thermotropic polyamide liquid crystal (a) and nylon 1010

[0048] Step (1): Same as example 1 step (1);

[0049] Step (2): Blending of Polyamide Liquid Crystal Polymer and Nylon 1010

[0050] 1) First, the polyamide liquid crystal polymer (a) is blended with nylon 1010 at a mass ratio of 10%, 20%, 30%, 40%, and 50%, respectively, and then vacuum-dried at 70°C for 56h, and then the polyamide Liquid crystal polymer (a) and nylon 1010 are simply mechanically pre-mixed, so that the two are fully mixed and uniform;

[0051] 2) Add the mixture of the pre-mixed polyamide liquid crystal polymer (a) and nylon 1010 into the extruder for melt blending, the number of revolutions per minute (rpm) of the rotor is 50, according to the principle of melting point matching, make it Melt blending with nylon 1010, the melting temperature is 230°C, and the blending time is 10min.

[0052] After melt-blending thermotropic polyamide liquid crystal (a) and nylon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com