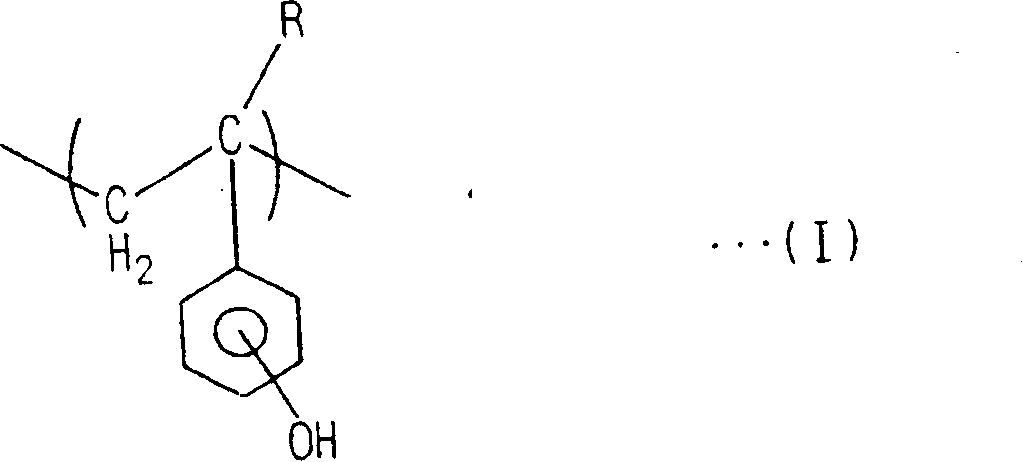

Plus photoresist composition and resist pattern forming method

A positive resist and resist pattern technology, which is applied in the photoengraving process of the pattern surface, the application of radioactive source radiation, and the photosensitive material used in optomechanical equipment, etc., can solve the problem of resolution, insufficient depth of focus, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

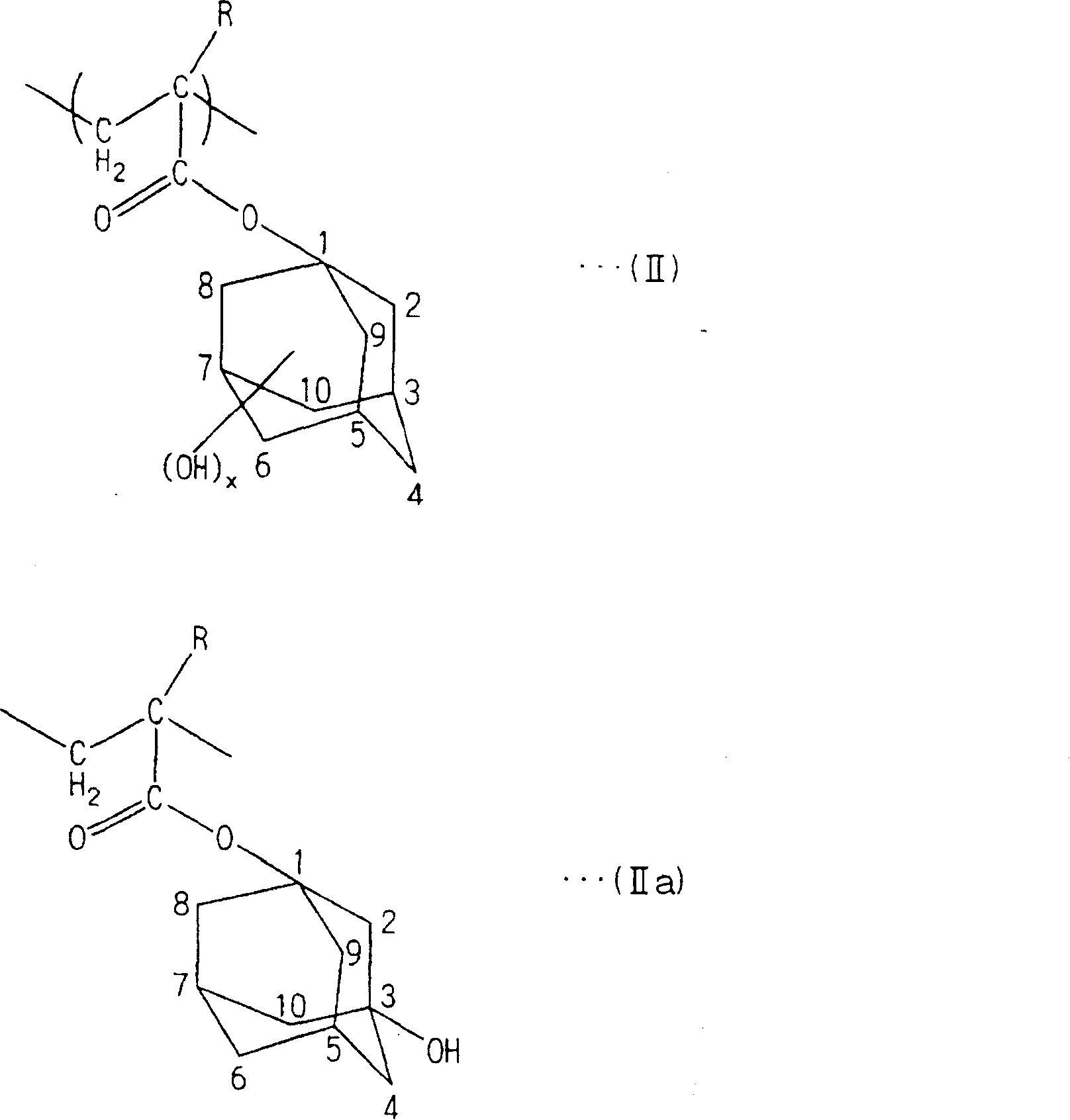

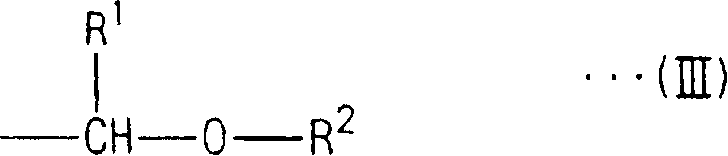

[0122] First prepare (A) component. That is, under an acid catalyst, the copolymer of p-hydroxystyrene and adamantyl methacrylate (molar ratio 8:2, Mw8500, Mw / Mn1.78) was reacted with ethyl vinyl ether to obtain a resin in which the hydroxyl group of the above-mentioned copolymer was protected with 1-ethoxyethyl, and it was used as (A) component.

[0123] use 1 H-NMR analysis of this resin revealed that the ratio of the number of 1-ethoxyethyl groups to the total number of hydroxyl groups of p-hydroxystyrene and adamantanol used was 20%. From this, it can be seen that the protection ratio of the hydroxyl group is 20 mol%.

[0124] In a mixed solvent of PGMEA and EL (the mass ratio of PGMEA:EL is 6:4), dissolve 100 parts by mass of the (A) component and the following amounts of each component relative to the 100 parts by mass of the (A) component, namely, 10 parts by mass of bis(cyclohexylsulfonyl)diazomethane and 2 parts by mass of triphenylsulfonium trifluoromethanesulfonat...

Embodiment 2

[0138] The same positive resist composition as in Example 1 was prepared. On the other hand, a substrate having an organic antireflection film (manufactured by Brewer Science, trade name DUV-44) having a film thickness of 65 nm was prepared on an 8-inch silicon wafer by coating and heating at 205°C.

[0139] The positive resist composition obtained above was applied on a substrate using a spinner. This was dried in advance at 100° C. for 90 seconds on a hot plate to form a resist layer with a film thickness of 560 nm.

[0140] Next, using a KrF scanner "NSR-S203B" (manufactured by Nikon, NA (numerical aperture) = 0.63, 2 / 3 band illumination), the KrF excimer laser was exposed through an 8% copper plate (H.T.) screen by the phase inversion method (248nm). Then, PEB treatment was performed at 110° C. for 60 seconds. Thereafter, at 23°C, it was developed with stirring for 60 seconds using a 2.38% by mass aqueous solution of tetramethylammonium hydroxide, and then rinsed with p...

Embodiment 3

[0148] In a mixed solvent of PGMEA and EL (the mass ratio of PGMEA:EL is 6:4), dissolve 100 parts by mass of component (A) used in Example 1, and the following amounts relative to 100 parts by mass of component (A) Each component, that is, 2 parts by mass of triphenylsulfonium trifluoromethanesulfonate and 3 parts by mass of triphenylsulfonium trifluoromethanesulfonate as (B) component, 0.5 parts by mass as (C) component Polypropylene glycol (Mw1000), 0.27 parts by mass of triethanolamine and 0.09 parts by mass of triisopropanolamine as components (D), so that the total of (A)-(D) is 500 parts by mass, thereby obtaining a positive resist combination things.

[0149] On the other hand, a substrate in which a 65-nm-thick organic antireflection film (manufactured by Brewer Science, trade name DUV-42) was formed on an 8-inch silicon wafer by heating was prepared.

[0150] The positive resist combination obtained above was applied on a substrate using a spinner. This was dried in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com