Power schottky device barrier method

A manufacturing method and device technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of poor reverse withstand voltage and anti-burnout ability of devices in forward and reverse characteristics, failure of barrier junction punch-through, Poor adhesion and other problems, to achieve the effect of improving reverse withstand voltage and reverse characteristics, avoiding surface defects and contamination, and reducing the influence of surface state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

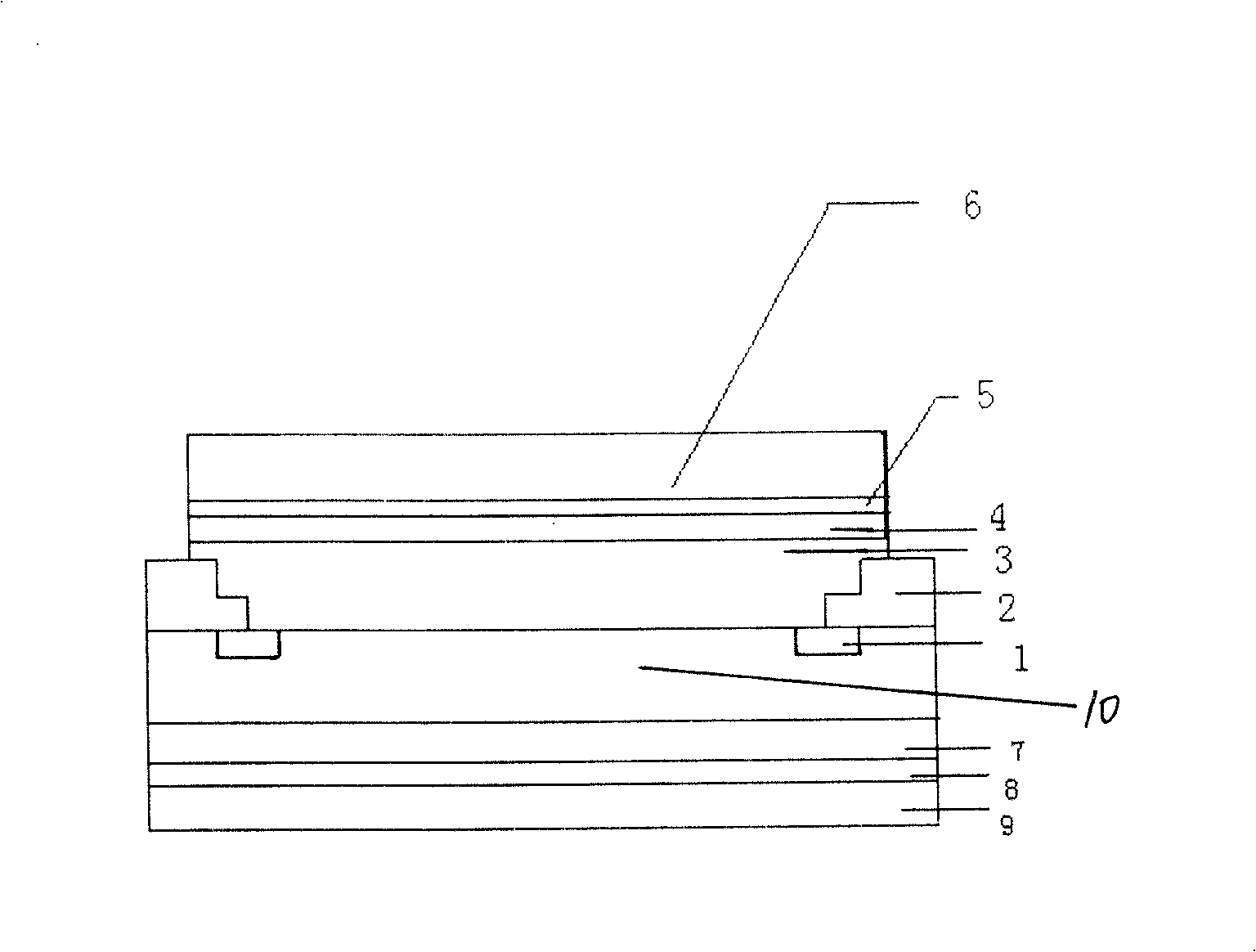

[0031] Accompanying drawing is a kind of specific embodiment of the present invention.

[0032] The method for manufacturing the barrier of a power Schottky device of the present invention comprises the following steps: oxidation→first photolithography→boron diffusion→second photolithography→sputtering barrier metal→evaporating multi-layer metal on the front side→three photolithography→annealing→ Backside thinning→backside evaporation→alloying→intermediate test and scribing and slicing.

[0033] The specific steps are:

[0034] a. Oxidation: Oxidize the silicon wafer to form an oxide layer SiO on its surface 2 ;

[0035] b. Perform a photolithography on the silicon wafer;

[0036] c. Boron diffusion: use the boron diffusion method of solid flake boron glass-ceramics to make a protective ring between the silicon wafer and the oxide layer;

[0037] d. Second photolithography;

[0038] e. Sputtering barrier metal: The barrier metal is prepared on the silicon wafer and the ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com