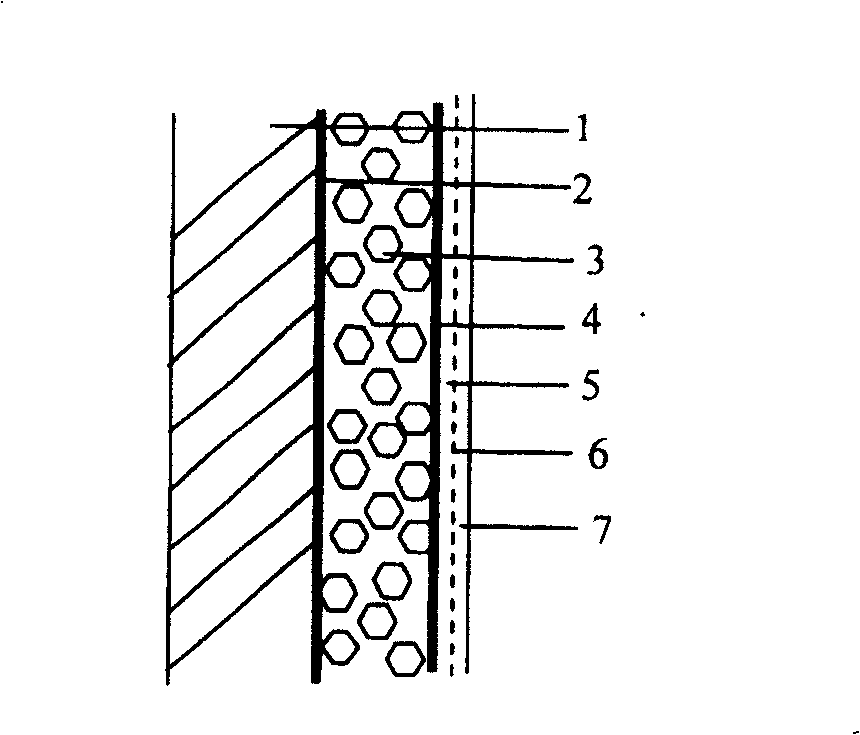

Full water foamed and sprayed polyurethane external heat insulation system

A technology of spraying polyurethane and full water foaming, which is applied in thermal insulation, building components, covering/lining, etc. It can solve the problems of easy corrosion of metal corner guards, affecting indoor temperature comfort, complex construction, etc., and achieves excellent thermal insulation and thermal insulation performance , good impermeability, improve the effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

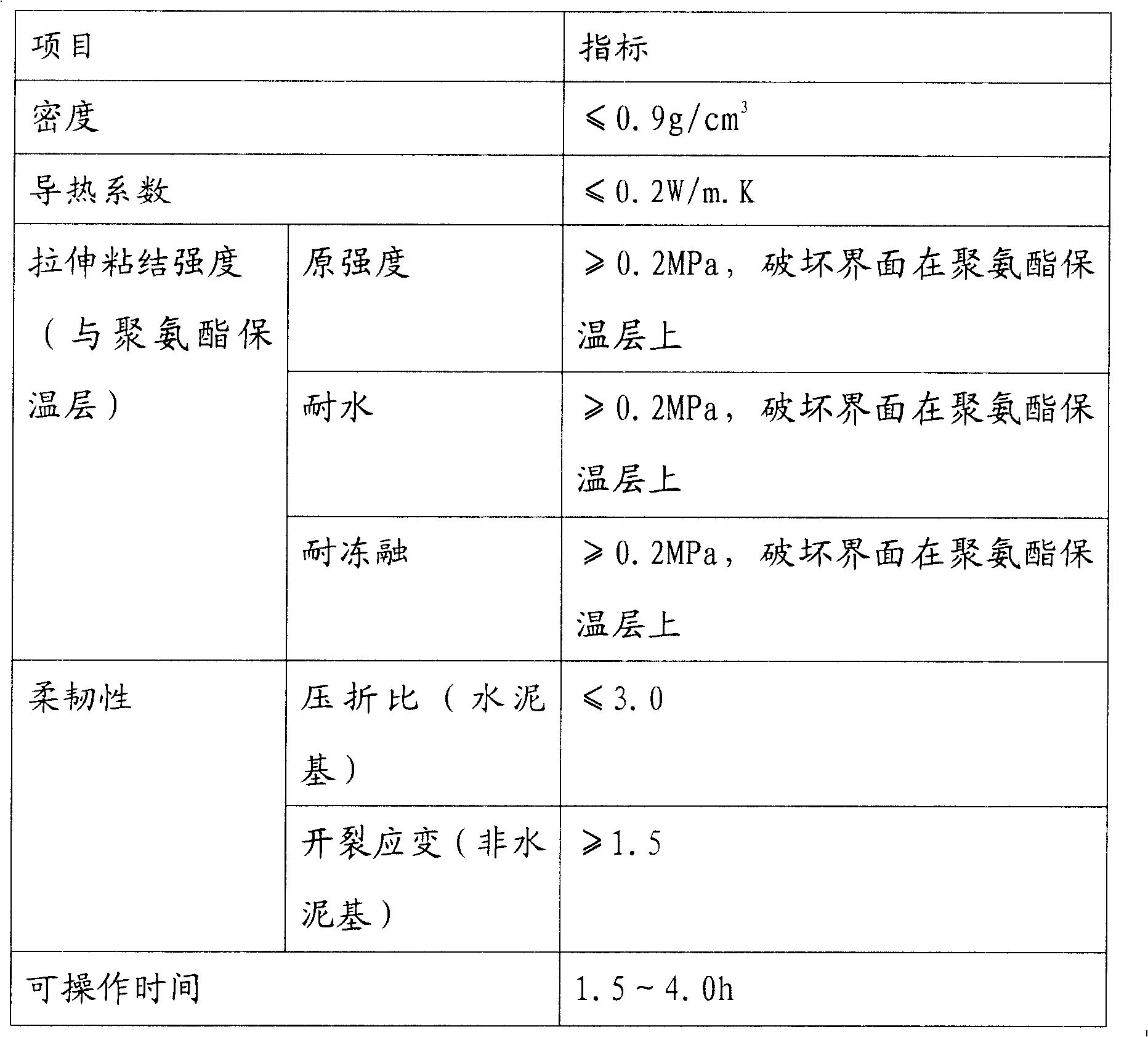

[0029] Example 1: 100 parts by weight of polyether, 1.0 parts by weight of foam stabilizer, 1.2 parts by weight of composite foam catalyst, 1.8 parts by weight of composite gel catalyst, and 1.5 parts by weight of water.

example 2

[0030] Example 2: 100 parts by weight of polyether, 2.0 parts by weight of foam stabilizer, 3.0 parts by weight of composite foaming catalyst, 1.0 parts by weight of composite gel catalyst, and 2.0 parts by weight of water.

example 3

[0031] Example three: 100 parts by weight of polyether, 3.0 parts by weight of foam stabilizer, 2.5 parts by weight of composite foam catalyst, 3.0 parts by weight of composite gel catalyst, and 4.5 parts by weight of water.

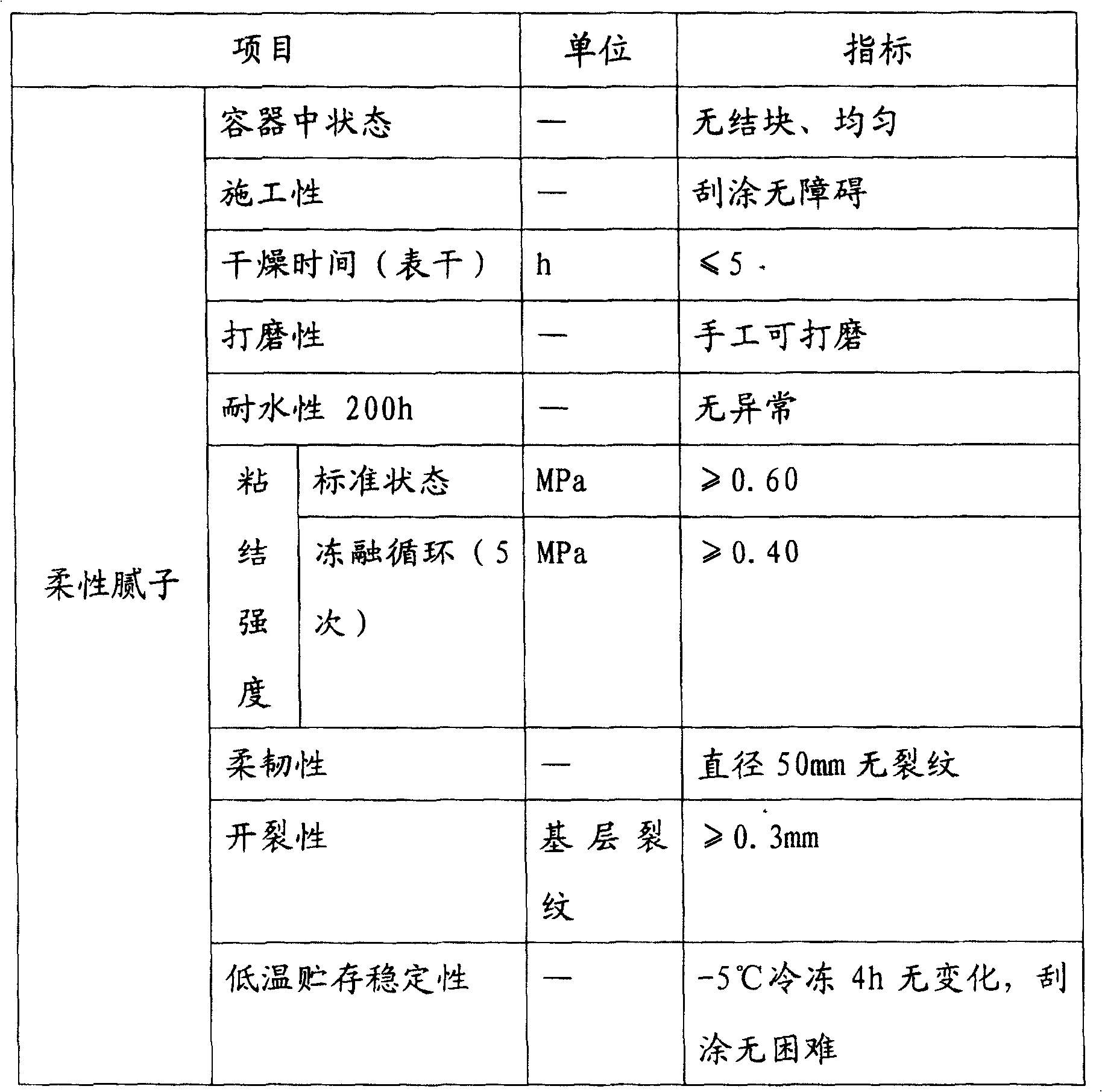

[0032] In another embodiment of the present invention, on the basis of the above embodiments, the grid cloth adopts reinforced alkali-resistant mesh cloth to increase the corrosion resistance of the mesh cloth and play a better reinforcing role. The mesh center distance of the grid cloth is selected as 10mm×10mm to improve the overall tensile strength.

[0033] In another embodiment of the present invention, on the basis of the first embodiment, the corner protector uses a plastic corner protector to replace the metal corner protector in the prior art to enhance its corrosion resistance.

[0034]In another embodiment of the present invention, on the basis of the first embodiment, a phase change energy storage material is added in the lightweight protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com