Process for disposing SOx in discharge gas

A technology for waste gas and waste water, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of large water evaporation, high water consumption and energy consumption, and achieve reduced evaporation, water consumption and energy consumption. , water consumption and energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Prepare the solution whose ammonium sulfate concentration is 90g / L, add sodium metaaluminate, make Al in the solution 2 o 3 The concentration of the solution is 9g / L, and then add ammonia water to adjust the pH value, so that the pH value of the solution is 13.

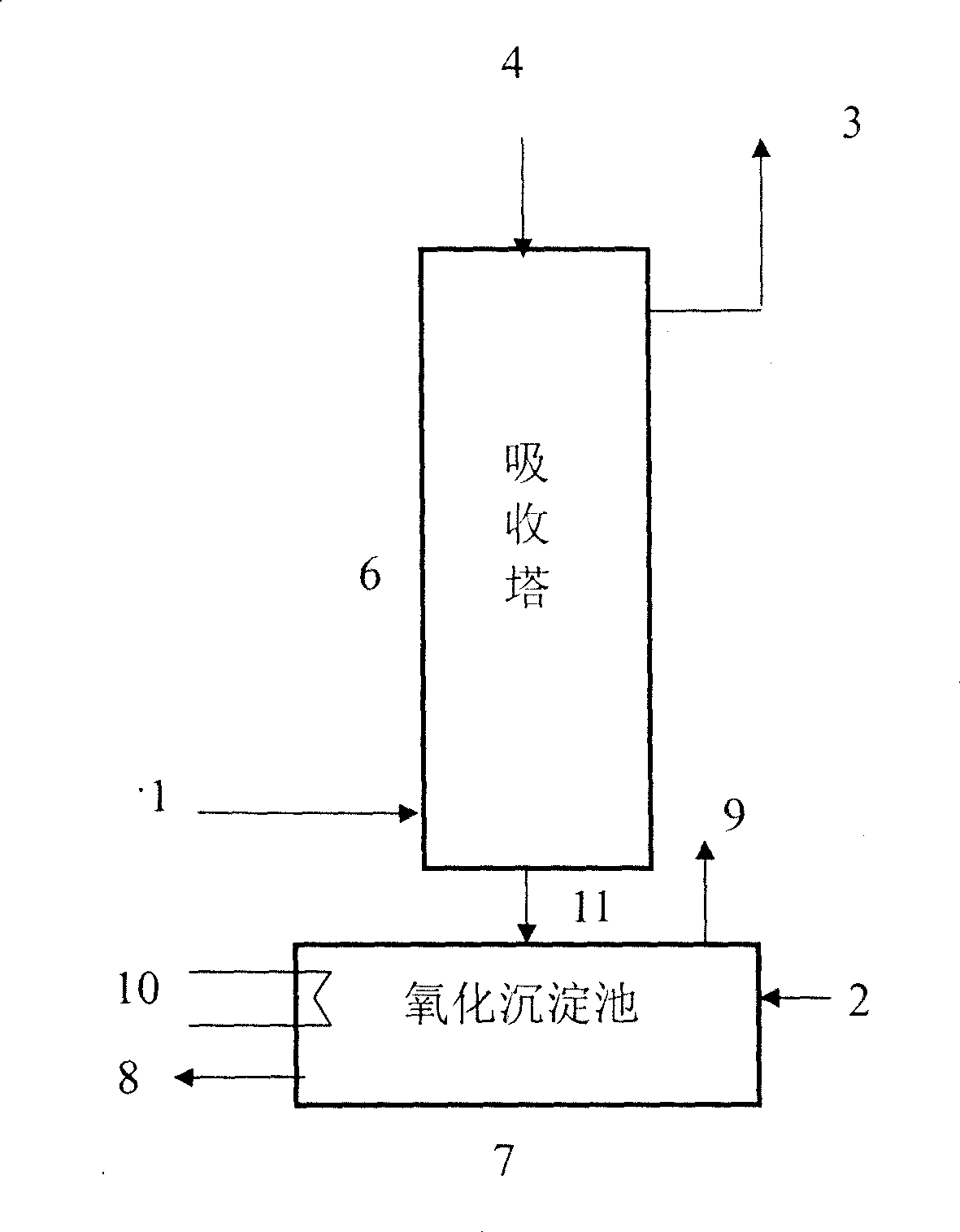

[0039] according to figure 1 In the process shown, in a laboratory small-scale absorption device (the ratio of height to diameter of the absorption tower is 5:1), the temperature of 130°C and SO x (the SO 2 with SO 3 The volume ratio is 9:1) the content is 2158mg / Nm 3 The FCC regenerated flue gas (taken from the catalytic cracking unit of Jinan Oil Refinery); the above prepared absorption liquid is heated to 60°C, sprayed from the top of the absorption device, and contacted with the waste gas rising from the bottom of the absorption tower, the gas and absorption liquid Volume ratio is 300Nm 3 / m 3 , the gas superficial velocity is 9000Nm 3 / (m 2 h); the contacted absorption liquid is collected in the s...

example 2

[0041] Absorption liquid uses catalyzer to produce molecular sieve to exchange and wash the wastewater containing ammonia nitrogen and silicon aluminum in this example (from Qilu Petrochemical Company Catalyst Factory molecular sieve device), wherein ammonium sulfate concentration is 18.1g / L, Al 2 o 3 The concentration is 3.6g / L, SiO 2 The concentration is 5.1g / L, and the pH value is 9.5.

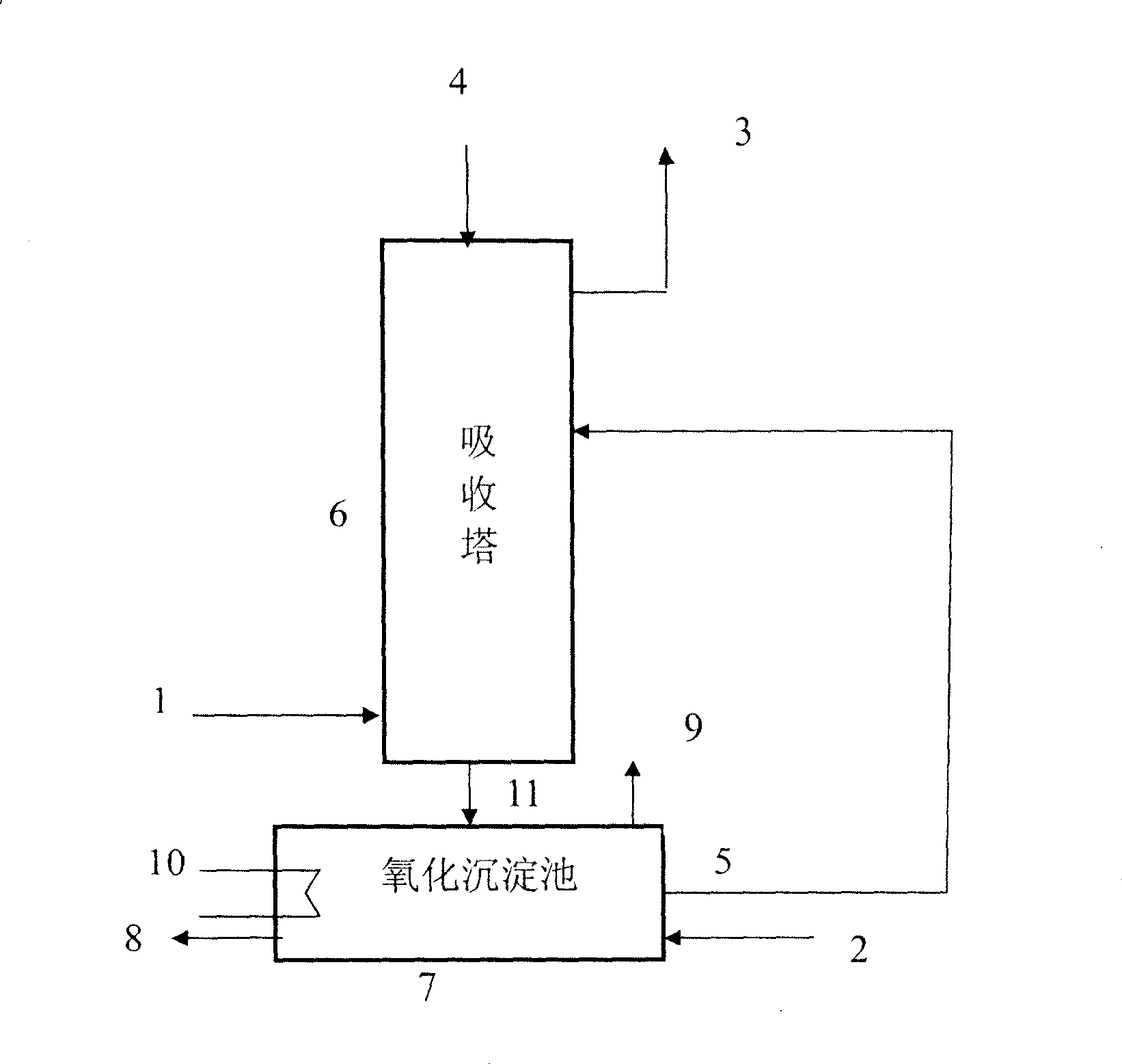

[0042] according to figure 2 In the process shown, in the laboratory small-scale absorption device, the temperature of 130 ℃, SO x The content is 2158mg / Nm 3 (the SO 2 with SO 3 The volume ratio is 9:1) of the FCC regenerated flue gas (taken from the catalytic cracking unit of Jinan Oil Refinery); the above-mentioned absorption liquid is heated to 80 ° C, sprayed from the top of the absorption unit and contacted with the waste gas rising from the bottom of the absorption tower; The contacted absorption liquid is collected in the storage tank at the bottom of the absorption tower, and...

example 3

[0044] Prepare a solution with an ammonium sulfate concentration of 150g / L, add sodium silicate, and make SiO in the solution 2 The concentration of the solution is 14g / L, then add ammonia water to adjust the pH value, so that the pH value of the solution is 11.

[0045] according to figure 1 In the process shown, in a laboratory small-scale absorption device (the ratio of height to diameter of the absorption tower is 5:1), the temperature of 130°C and SO x (the SO 2 with SO 3 The volume ratio is 9:1) the content is 2158mg / Nm 3 The FCC regenerated flue gas (taken from the catalytic cracking unit of Jinan Oil Refinery); the above prepared absorption liquid is heated to 90°C, sprayed from the top of the absorption device, and contacted with the waste gas rising from the bottom of the absorption tower, the gas and absorption liquid The volume ratio is 300Nm 3 / m 3 , the gas superficial velocity is 9000Nm 3 / (m 2 h); the contacted absorption liquid is collected in the stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com