Process for preparing biological active peptide for improving lactic acid bacteria proliferation and fermentation to produce acid

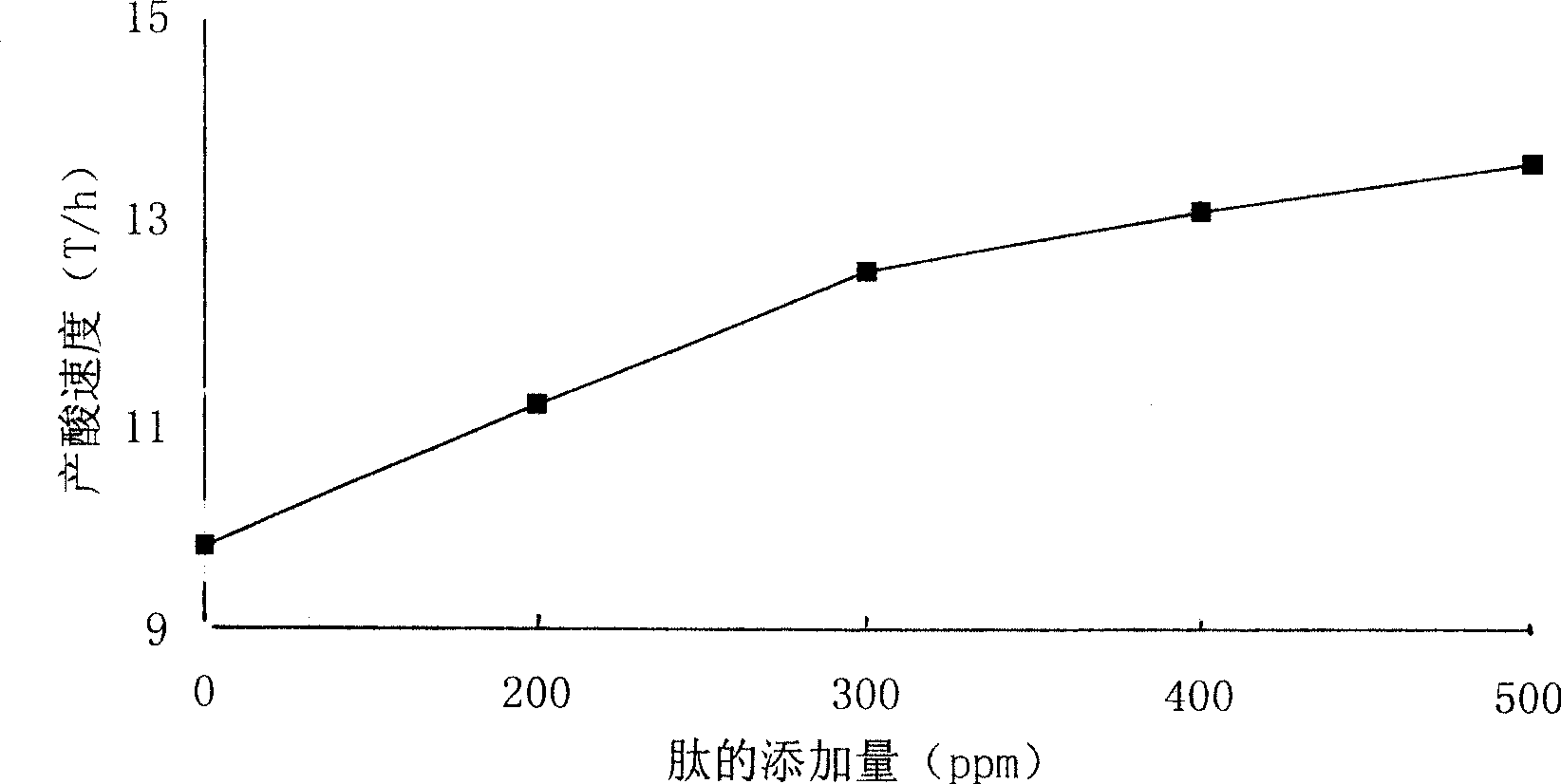

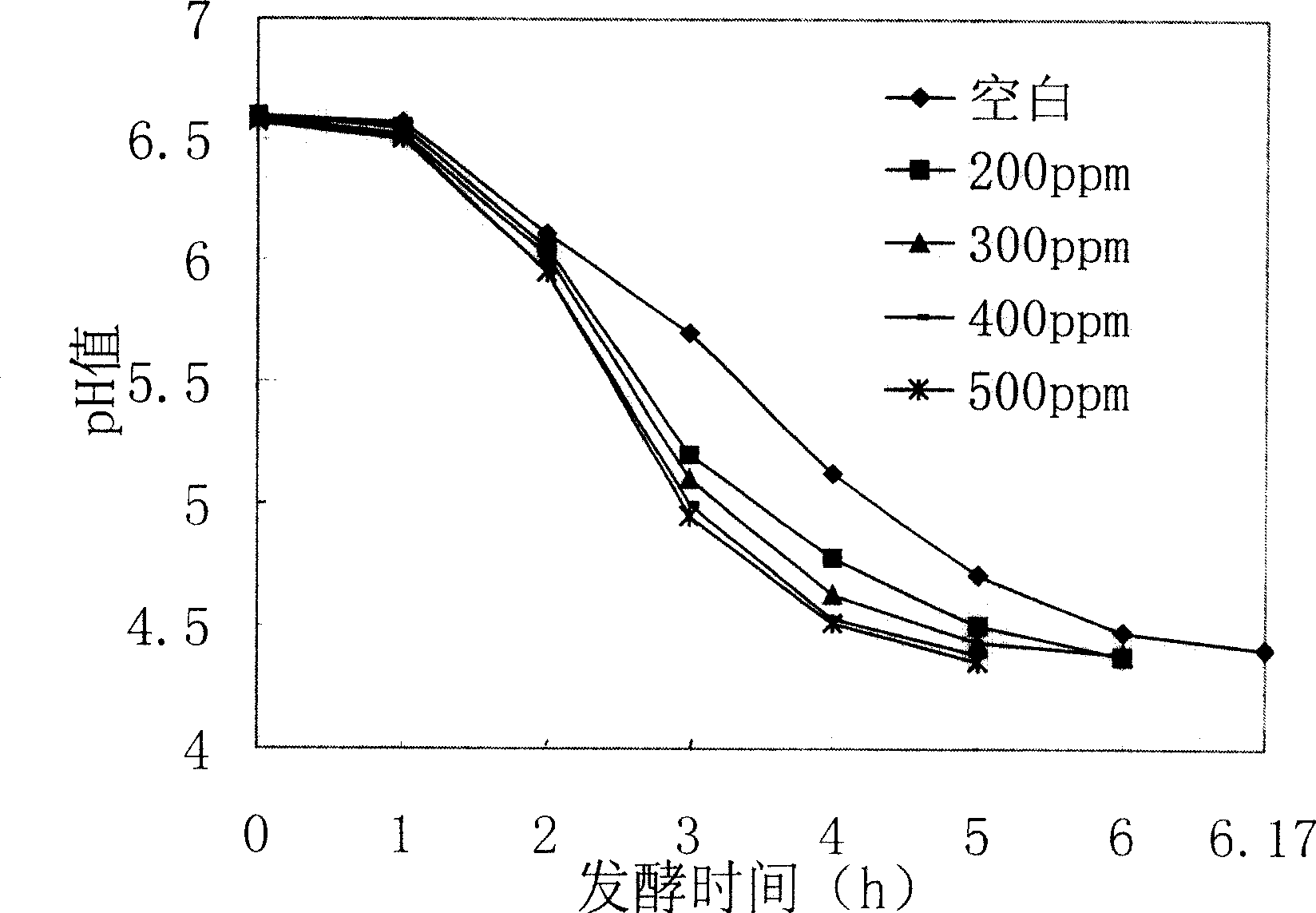

A bioactive peptide, lactic acid bacteria technology, applied in the directions of fermentation, dairy products, milk preparations, etc., can solve the problems of bad flavor, bad smell and high cost of yogurt, and achieve the goal of promoting the proliferation of lactic acid bacteria, high protein utilization rate and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Disperse 8% (w / v) soybean protein in water, heat at 90°C for 20min, cool to 60°C; add papain 3000U / g protein, pH 8.0, carry out enzymatic hydrolysis reaction at 55°C, use pH-Stat method to control the degree of hydrolysis to 5%; add trypsin 2000U / g protein, pH 8.0, carry out the enzymolysis reaction at 55°C, use the pH-Stat method to control the degree of hydrolysis to 10.2%; adjust the pH value of the enzymolysis solution to pH The value is 3, kept at 70°C for 30 minutes to inactivate the protease; adjust the pH value to neutral; pass the enzymolysis solution through a 5000 molecular weight ultrafiltration membrane to remove large molecular weight polypeptides and proteins, and obtain rich in lactic acid bacteria that promote the proliferation and fermentation of acid production The distribution of biologically active peptides is mainly concentrated in the range of 500-2000.

Embodiment 2

[0028] Disperse 8% (w / v) soybean protein in water, heat at 85°C for 15 minutes, cool to 60°C; add papain 2000U / g protein, pH 8.0, carry out enzymatic hydrolysis reaction at 55°C, use pH-Stat method to control the degree of hydrolysis to 5.6%; add chymotrypsin 2500U / g protein, pH 8.0, carry out the enzymolysis reaction at 55°C, use the pH-Stat method to control the degree of hydrolysis to 11.8%; adjust the pH value of the enzymolysis solution To pH 2, keep at 68°C for 25 minutes to inactivate the protease; adjust the pH to neutral; pass the enzymolysis solution through a 5000 molecular weight ultrafiltration membrane to remove large molecular weight polypeptides and proteins, and obtain rich lactic acid bacteria to promote proliferation and fermentation The molecular weight distribution of acid-producing bioactive peptides is mainly concentrated in the range of 500-2000.

Embodiment 3

[0030] Disperse 8% (w / v) soybean protein in water, heat at 80°C for 10min, cool to 55°C; add alkaline protease (Alcalase TM ) 2500U / g, pH 8.5, carry out enzymatic hydrolysis at 60°C, use pH-Stat method to control the degree of hydrolysis to 5.5%; add chymotrypsin 2500U / g protein, pH 8.5, carry out enzymatic hydrolysis at 55°C , using the pH-Stat method to control the degree of hydrolysis to 11.8%; adjust the pH value of the enzymatic solution to pH 2.5, and keep it at 60°C for 35 minutes to inactivate papain; adjust the pH value to neutral; The 5000 molecular weight ultrafiltration membrane removes large molecular weight polypeptides and proteins, and obtains bioactive peptides rich in promoting the proliferation of lactic acid bacteria and fermenting acid production. The molecular weight distribution is mainly concentrated in 500-2000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com