Bound-type composite heat-insulation wall with support body

A composite thermal insulation and binding technology, applied in thermal insulation, walls, pins, etc., can solve the problems of affecting thermal insulation effect, reducing thermal resistance, and high cost, achieving the effects of strong construction feasibility, reliable connection and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

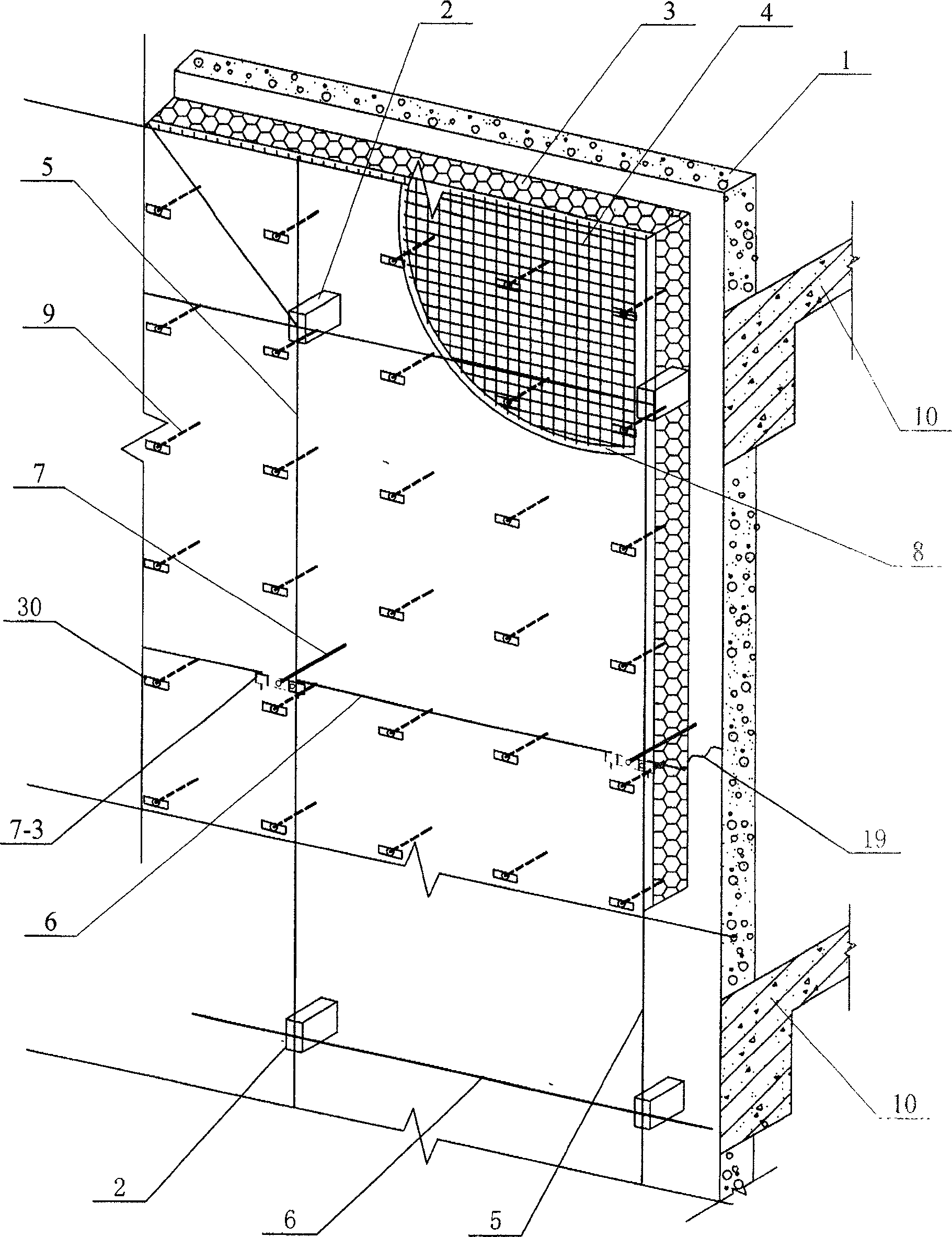

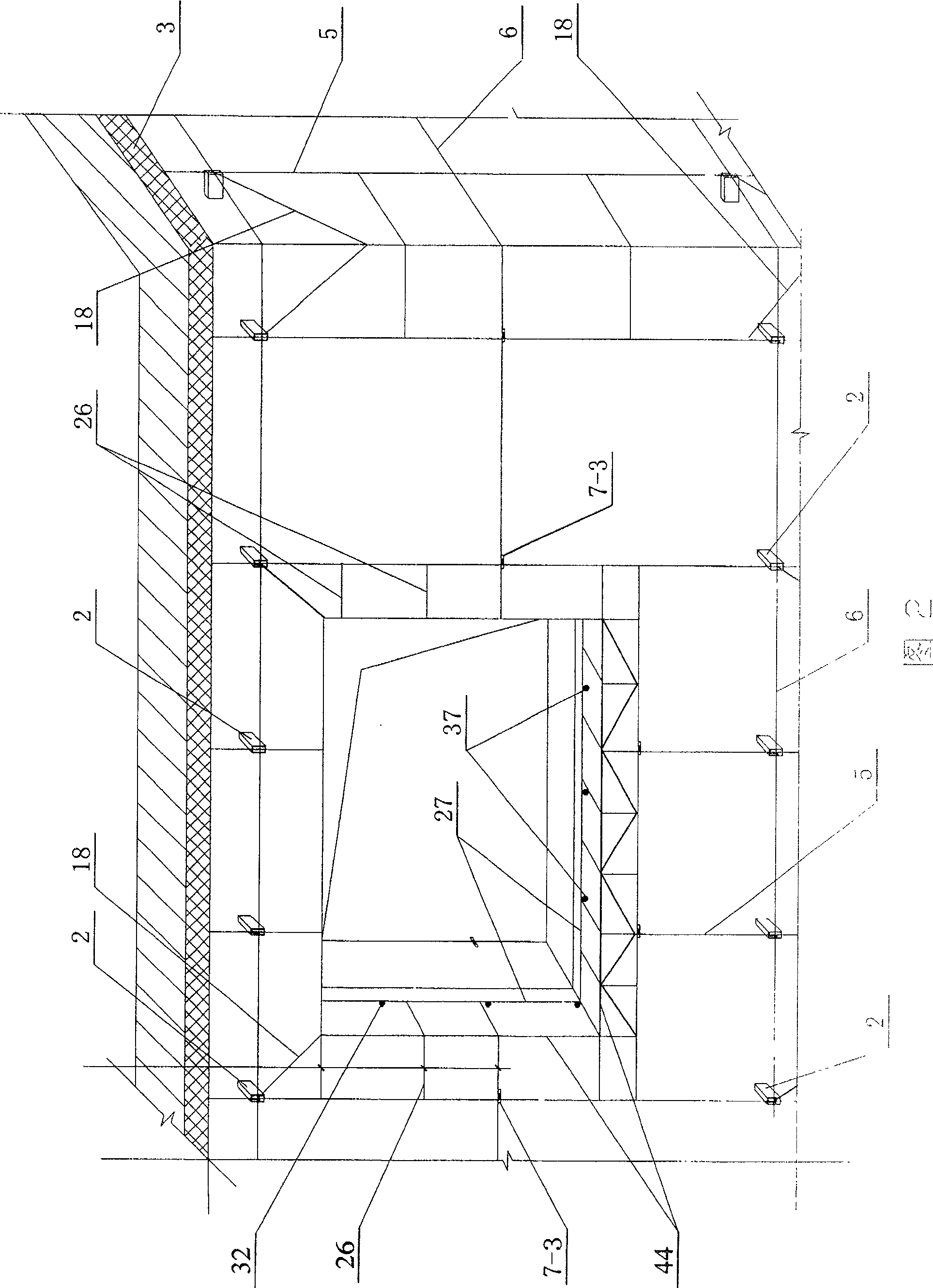

[0013] Specific embodiment one: (see figure 1 , Figure 2, Figure 6, Figure 8, Figure 16, Figure 17, Figure 19 , Figure 20, Figure 27) This embodiment is composed of a base wall 1, a concrete cantilever beam support 2, an insulation layer 3, a metal mesh 4, a vertical steel bar 5, an outer protective layer 8 and a concrete member 10 of the main structure of the building The concrete component 10 of the main structure of the building includes concrete ring beams, concrete beams, concrete pillars, concrete walls, concrete lintels, concrete foundations, concrete balcony slabs, and window side concrete walls connected to the concrete on the upper and lower floors. Column or concrete window sill, the inner end of the concrete cantilever beam support 2 is fixed on the inner or outer surface of the concrete member 10 of the main structure of the building and connected with steel members, or fixed in the base wall 1 of the load-bearing masonry, The outer side of the base wall 1 and the c...

specific Embodiment approach 2

[0015] Specific embodiment 2: In this embodiment, the thermal insulation layer 3 is a polymer mortar prepared with adhesive or plastic expansion nails 9 and fixed on the base wall 1 or on the main structure of the building, or the thermal insulation layer 3 is fixed by sticking nails. , The inner end of the plastic expansion nail 9 is fixed in the base wall 1, and the outer end of the plastic expansion nail 9 is clamped and fixed to the heat preservation board. At present, the commonly used adhesives are adhesives made of polyacrylate emulsion or vinyl acetate-ethylene emulsion and added cellulose, preservatives and other materials to bond with cement and sand to prepare polymer mortar. Polyacrylate emulsions include pure acrylic emulsion, Styrene-acrylic emulsion, silicon-acrylic emulsion, etc., are adhesives with good durability and good bonding performance. When the material of the insulation layer 3 is different, the selected adhesive should match it.

specific Embodiment approach 3

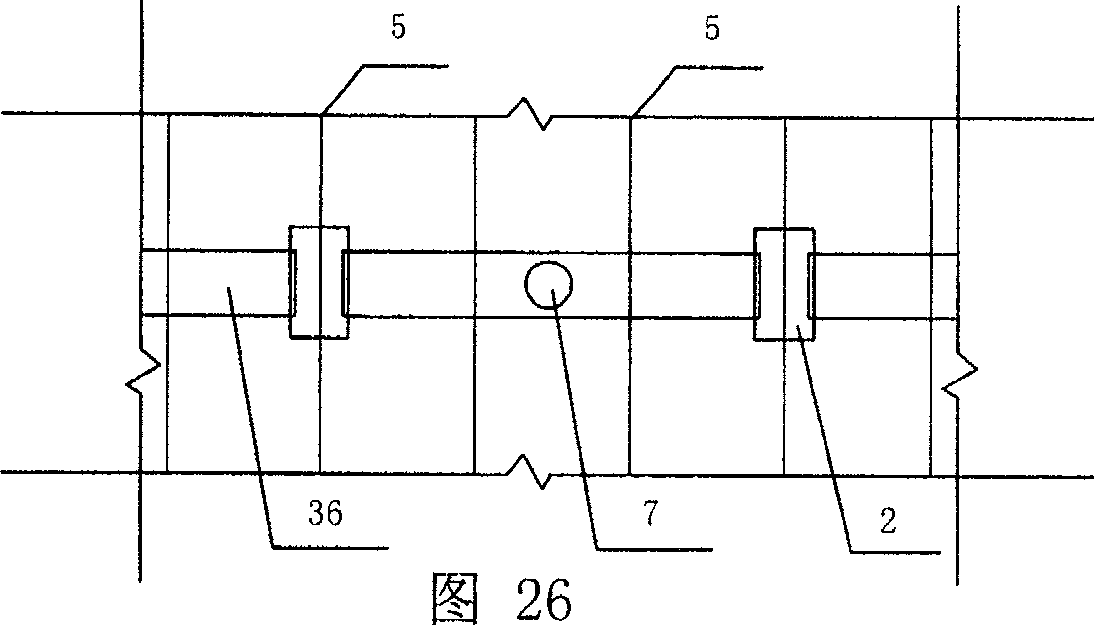

[0016] Specific implementation mode three (see figure 1 , Figure 2, Figure 6-8, Figure 10-17): This embodiment is different from the first embodiment in that an inner and outer pull connection member 7 is added, and the inner end of the inner and outer pull connection member 7 is connected to the base wall 1 Or the concrete members 10 of the main structure of the building are fixedly connected, and the outer ends of the inner and outer pull-connecting pieces 7 are connected and fixed with the vertical steel bars 5 in the outer protective layer 8. The function of the internal and external pull connectors is to reliably tie and fix the vertical steel bars with the base wall or with the concrete members of the main structure of the building at a certain distance on the vertical steel bars. The installation of the internal and external pull connectors can reduce the support of the concrete cantilever beams. The distance between the upper and lower parts reduces thermal bridges and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com