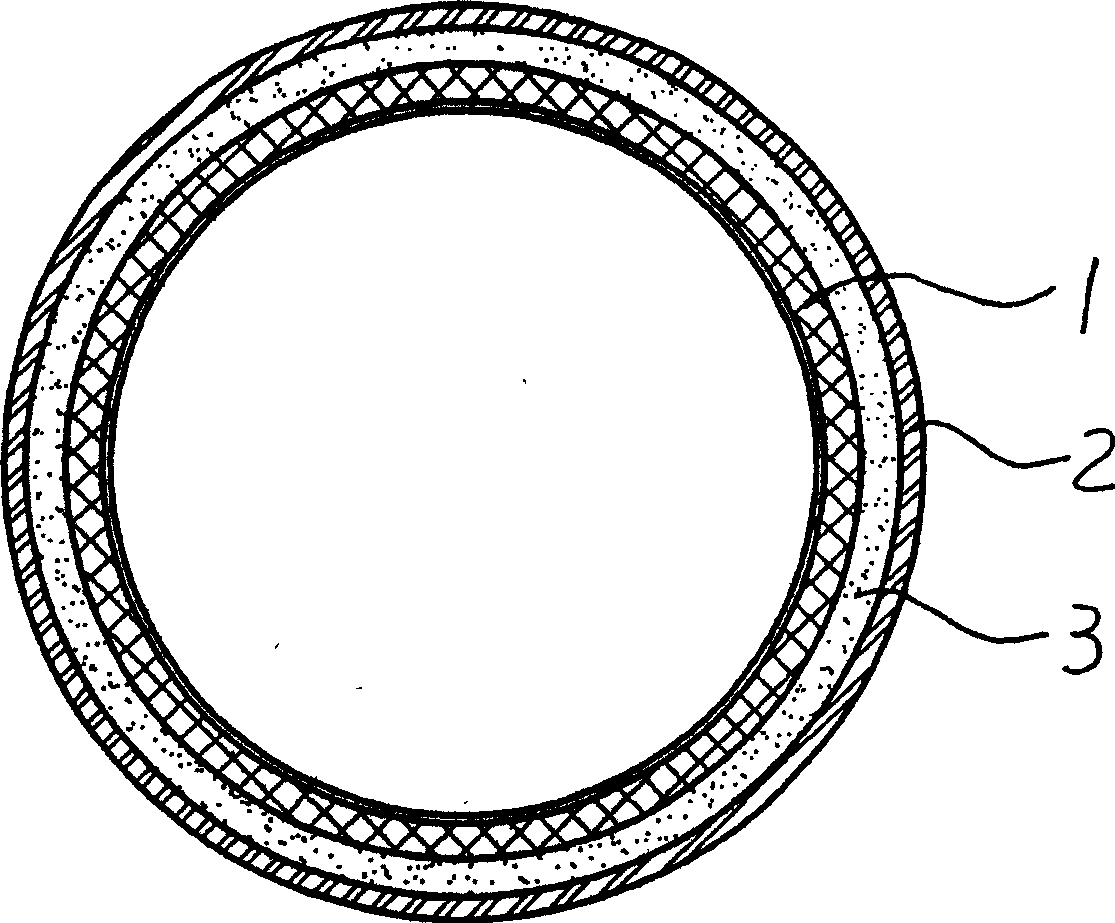

Glass reinforced plastic device for coal chemical industry engineering and method for preparing the same

A technology for coal chemical industry and glass fiber reinforced plastic is applied in the field of production technology for preparing the above-mentioned glass fiber reinforced plastic container device, which can solve the problems of corrosion of the inner wall surface, poor mechanical strength and bending resistance of the wall and bottom of the electrolytic tank, and achieves the improvement of mechanical strength and strength. Corrosion resistance and longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The first step: the preparation of the mold

[0037] Prepare tank (can) molds as required, and make the surface free of pits, dust, sundries and other attachments, and the surface of the mold should be smooth;

[0038] The second step: coating process

[0039] In order to facilitate demoulding and smooth the inner surface of the FRP device, first coat a layer of talcum powder or waxy release agent on the surface of the mold, and then coat a layer of polyester film on the surface of the mold, the overlapping width of the film is 1-2cm , the thickness is between 20 ~ 40um;

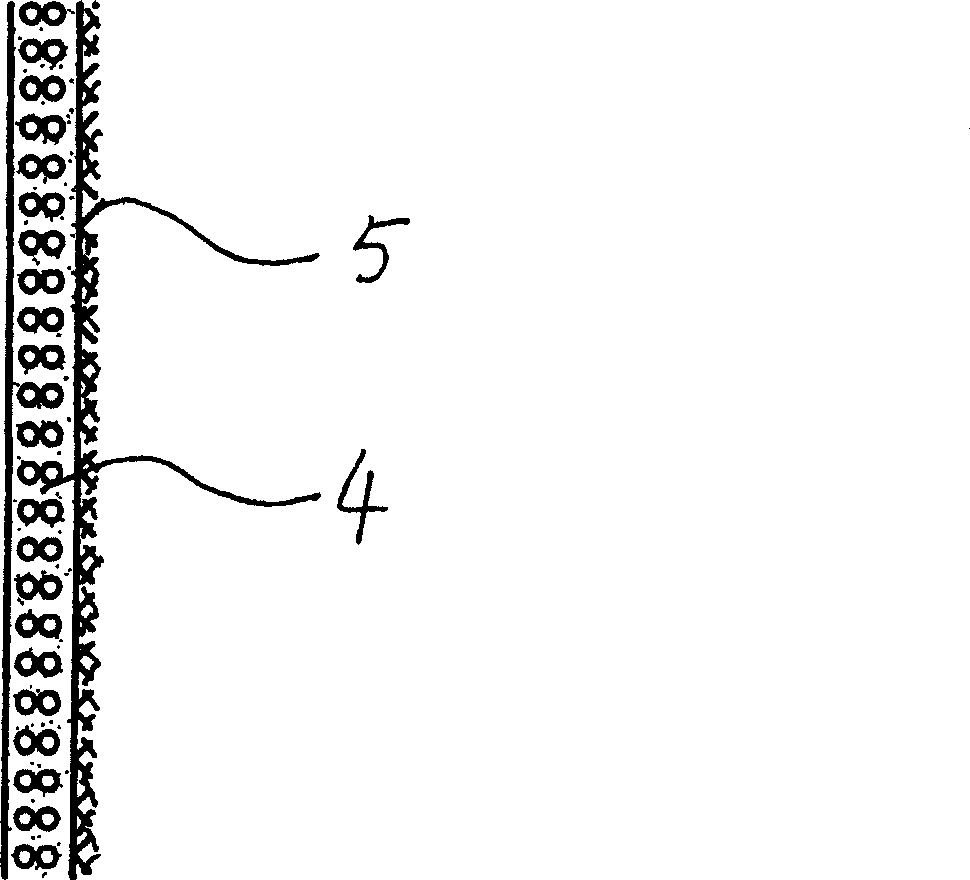

[0040] The third step: the spraying process of the inner anti-corrosion layer

[0041] The resin used to configure the inner anti-corrosion layer:

[0042]First get 100 parts by weight of SWANCOR901 type vinyl ester resin produced by Shangwei (Shanghai) Fine Chemical Co., Ltd., then add 1.2 parts by weight and 0.1% cobalt octanoate as catalyst;

[0043] Take 0.5 parts by weight and a concentration...

Embodiment 2

[0052] The preparation of the first step and the second step mold and the mold coating process are the same as in Example 1.

[0053] The third step: the spraying process of the inner anti-corrosion layer

[0054] The resin used to configure the inner anti-corrosion layer:

[0055] First get 100 parts by weight of SWANCOR901 type vinyl ester resin produced by Shangwei (Shanghai) Fine Chemical Co., Ltd., then add 1.5 parts by weight and 0.5% cobalt octanoate as catalyst;

[0056] Get 1.0 parts by weight, concentration of 60% methyl peroxide as curing agent and join in the above-mentioned vinyl ester resin by spray gun;

[0057] Stir the above-mentioned vinyl ester resin with catalyst and curing agent evenly, and spray it evenly on the mold coated with polyester film;

[0058] Evenly wind the glass fiber surface mat layer with a thickness of 0.1-0.5 cm on the sprayed inner anti-corrosion layer resin to form an inner surface mat layer with anti-leakage function;

[0059] The f...

Embodiment 3

[0065] The preparation of the first step and the second step mold and the mold coating process are the same as in Example 1.

[0066] The third step: the spraying process of the inner anti-corrosion layer

[0067] The resin used to configure the inner anti-corrosion layer:

[0068] First get 100 parts by weight of SWANCOR901 type vinyl ester resin produced by Shangwei (Shanghai) Fine Chemical Co., Ltd., then add 1.0 parts by weight and 0.3% cobalt octanoate as catalyst;

[0069] Get 3.0 parts by weight, concentration of 30% methyl peroxide as curing agent and join in the above-mentioned vinyl ester resin by spray gun;

[0070] Stir the above-mentioned vinyl ester resin with catalyst and curing agent evenly, and spray it evenly on the mold coated with polyester film;

[0071] Evenly wind the glass fiber surface mat layer with a thickness of 0.1-0.5 cm on the sprayed inner anti-corrosion layer resin to form an inner surface mat layer with anti-leakage function;

[0072] The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com