Stator of motor

A motor stator and positioning structure technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, electrical components, etc., can solve problems such as uneven shrinkage, complex structure, assembly deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to achieve the above-mentioned purpose and effect, the technical means and the structure thereof adopted in the present invention are illustrated in detail in the form of an embodiment, and its features and functions are as follows, so that it can be fully understood.

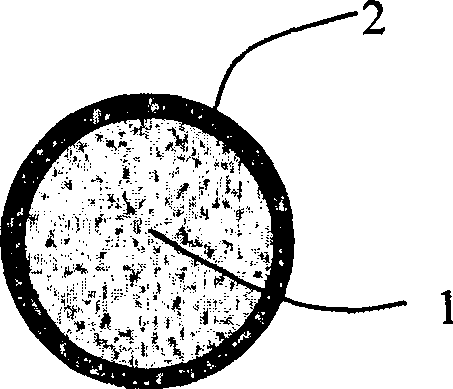

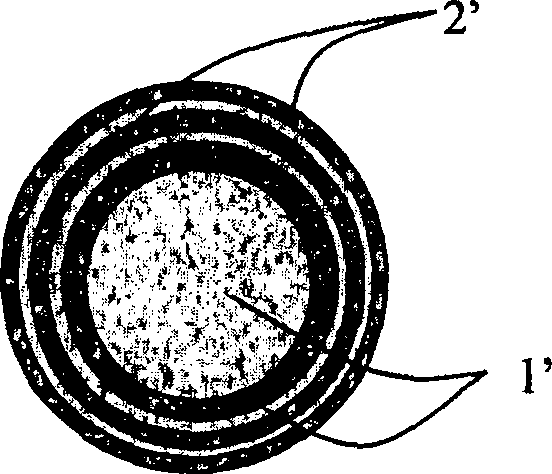

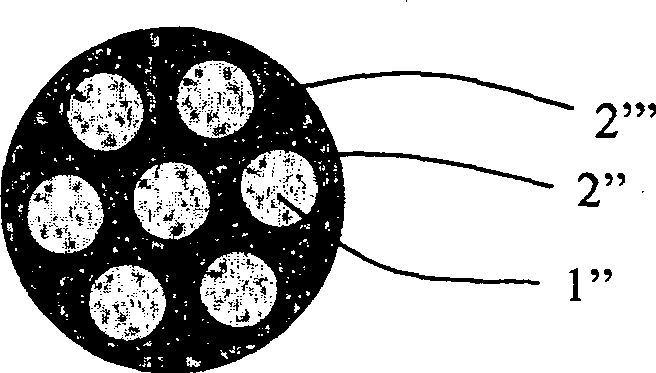

[0024] According to the embodiment of the present invention, the magnetic raw material of the magnetic pole plate of the motor stator adopts a composite soft magnetic metal material with a core-shell structure, which is very different from the conventional commercial iron core powder, mainly by adding low solid solution Or non-main phase materials without solid solution, and use the diffusion-precipitation mechanism of powder sintering theory or heterogeneous interface coating technology, and then use high (low) temperature treatment to make it between grains or between powder clusters and A core-shell structure is formed between the powder clusters.

[0025] see figure 1 , the core-shell stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com