Cell culturing rack material and its preparation

A scaffold material and cell culture technology, applied in coating and other directions, can solve problems such as unfavorable cell growth and culture, low porosity, and poor penetration of pores up and down, achieve optimal tissue compatibility, overcome poor strength, and a good growth environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

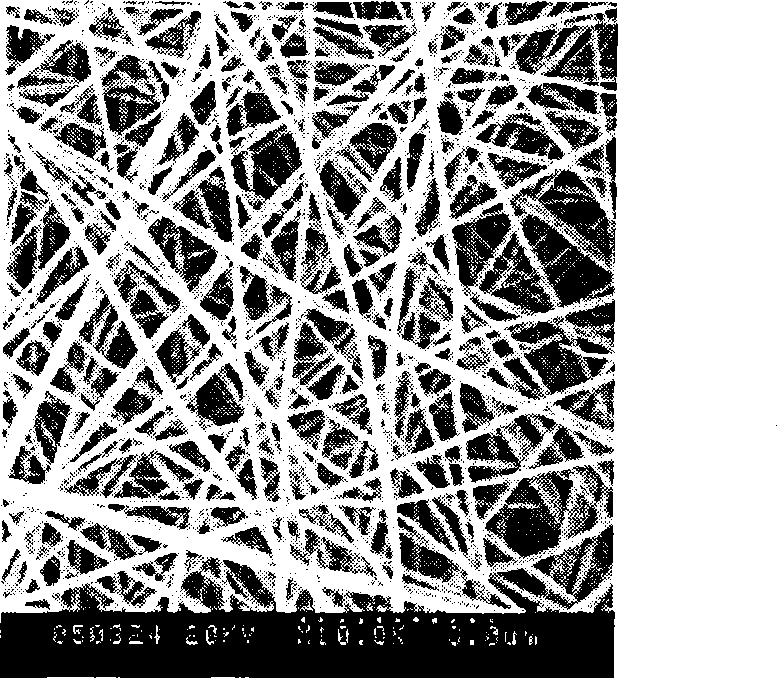

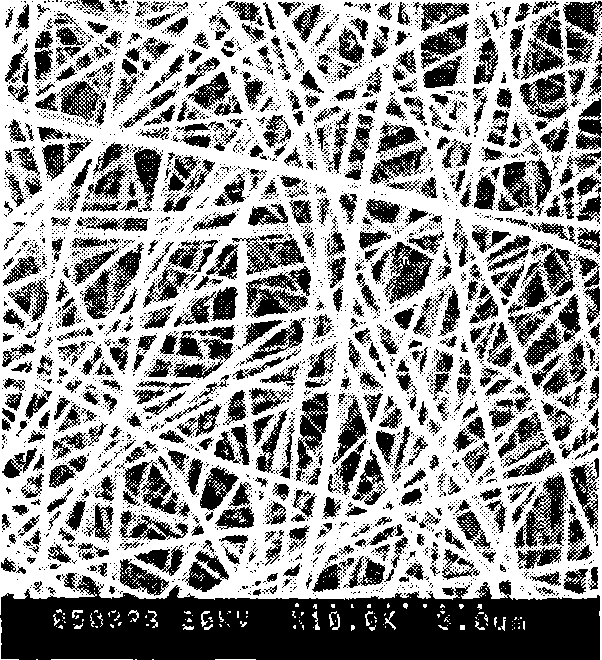

Image

Examples

Embodiment 1

[0026] 1. Put 0.2kg of waste mulberry silk into 6L of sodium carbonate aqueous solution with a concentration of 0.05%, boil for 0.5h, repeat the treatment three times, and remove the sericin around the silk to obtain silk fibroin, which is air-dried at room temperature;

[0027] 2. Use 1.2L of calcium chloride, water and ethanol solution with a molar ratio of 1:8:2 to dissolve the dried silk fibroin into a silk fibroin solution by heating at 78±2°C;

[0028] 3. Pour the silk fibroin solution prepared in step 2 into a cellulose dialysis bag, first dialyze with tap water, and then dialyze with deionized water to remove ethanol and calcium chloride small molecules in the solution, and then use multi-layer degreasing Filtration with gauze to obtain pure silk fibroin solution;

[0029] 4. Take 100ml of pure silk fibroin solution and pour it into an area of 20×20cm 2 In the polystyrene plastic tray, dry at constant temperature and humidity (25°C, RH65%) to form a film, remove the...

Embodiment 2

[0036]1. Put 0.1kg of lower leg silk into 3L of sodium carbonate aqueous solution with a concentration of 0.05%, boil for 0.5h, repeat the treatment three times, and remove the sericin around the silk to obtain silk fibroin;

[0037] 2. The dried silk fibroin obtained in step 1 is heated and dissolved into a silk fibroin solution with 0.6L of calcium chloride, water and ethanol solution with a molar ratio of 1:8:2 at 78±2°C;

[0038] 3. Pour the above silk fibroin solution into a cellulose dialysis bag, first dialyze it with tap water, and then dialyze it with deionized water to remove ethanol and calcium chloride small molecules in the solution, and then filter with multi-layer degreased gauze. Obtain pure silk fibroin solution;

[0039] 4. Take 100ml of pure silk fibroin solution and pour it into an area of 20×20cm 2 In a stainless steel plate, frozen at -20 °C for 8 h, and then placed in a freeze dryer for vacuum drying for 20 h to obtain a sponge-like regenerated silk f...

Embodiment 3

[0046] 1. Put 0.2kg of waste mulberry silk into 6L of sodium carbonate aqueous solution with a concentration of 0.05%, boil for 0.5h, repeat the treatment three times, and remove the sericin around the silk to obtain silk fibroin, which is air-dried at room temperature;

[0047] 2. Use 1.2L of calcium chloride, water and ethanol solution with a molar ratio of 1:8:2 to dissolve the dried silk fibroin into a silk fibroin solution by heating at 78±2°C;

[0048] 3. Pour the silk fibroin solution prepared in step 2 into a cellulose dialysis bag, first dialyze with tap water, and then dialyze with deionized water to remove ethanol and calcium chloride small molecules in the solution, and then use multi-layer degreasing Filtration with gauze to obtain pure silk fibroin solution;

[0049] 4. Take 100ml of pure silk fibroin solution and pour it into an area of 10×20cm 2 In the polystyrene plastic tray, dry at constant temperature and humidity (25°C, RH65%) to form a film, remove the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com