Process for preparing notoginseng triol saponin and use thereof

A technology of triol saponin and alcohol saponin, which is applied in the preparation field of extracting notoginseng triol saponin from Panax notoginseng, to achieve the effect of convenient taking, fast absorption and increasing arterial blood flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

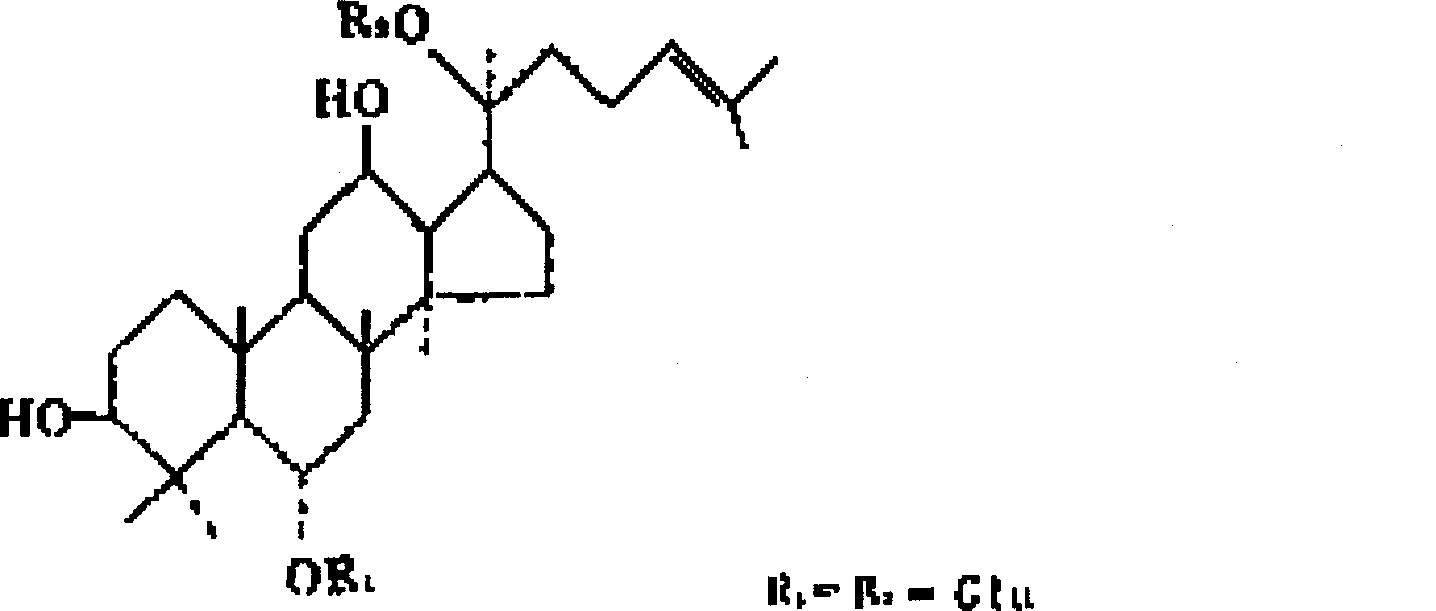

[0038] Example 1: Chemical composition of panaxtriol saponin (PTS)

[0039] ①, Notoginsenoside C 1 、D 1 separation

[0040] Thin-layer silica gel (10-40 μ produced by Qingdao Ocean Chemical Factory) dry packing ( 42*400mm). PTS is dissolved in dilute alcohol, mixed with a thin layer of silica gel, dried at low temperature, loaded on the top of the column, and the lower phase of chloroform-methanol-water (65:35:10) is the developing solvent, received by the automatic sampling receiver, each 20 ml . Thin-layer chromatography identification, spotting on high-efficiency thin-layer silica gel plate (produced by Qingdao Ocean Chemical Factory), and developing on the horizontal development tank, the developing solvent is the same as the developing agent system of column chromatography, drying in the air after development, spraying with sulfuric acid ethanol solution, 105 Bake at ℃ for 5 minutes, or bake with hot air with an electric hair dryer, take the fractions with the same ...

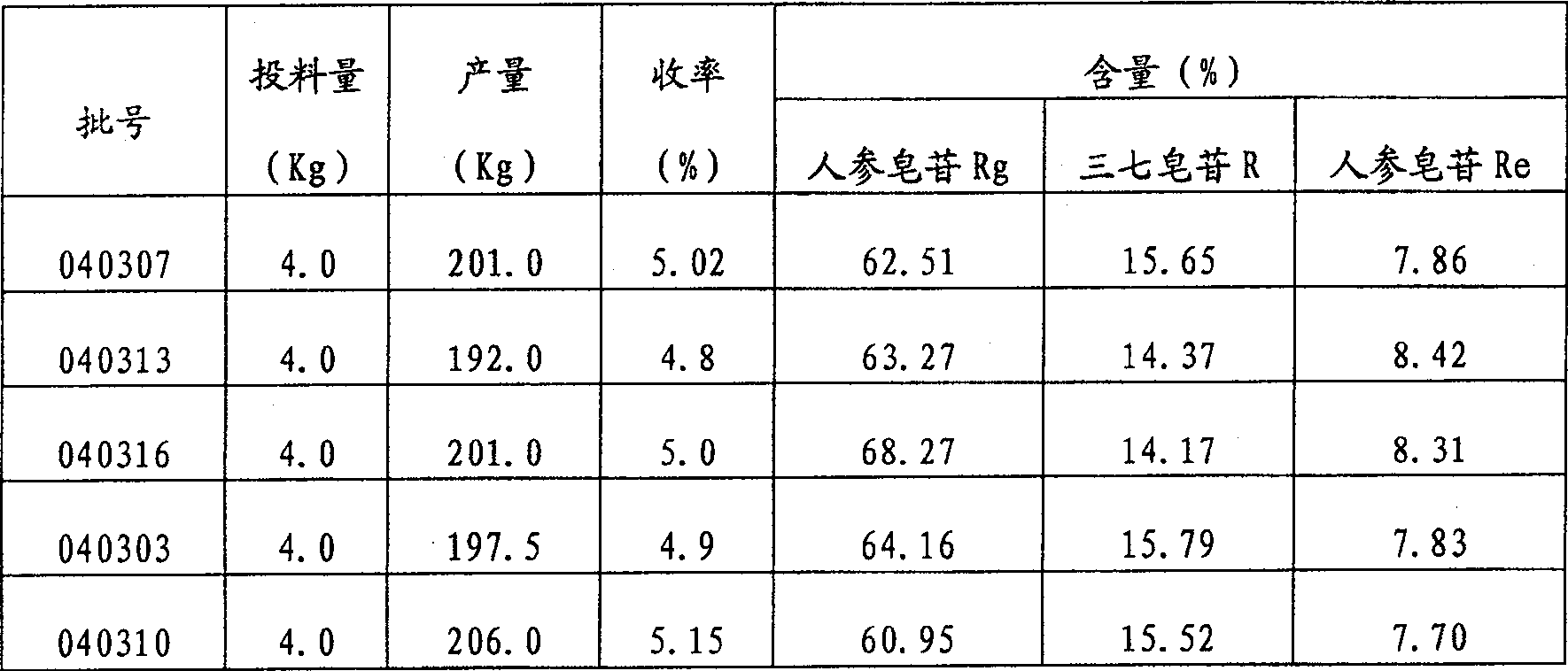

example 2

[0101] Example 2: Prepare notoginseng triol saponin according to the following steps:

[0102] A. Take notoginseng and crush it through No. 1 sieve, add 60% ethanol to soak for 14 hours, then evenly compact and fill it into the percolation barrel;

[0103] B. Percolation of 60% ethanol with 6 times the amount of medicinal materials until the effluent has no saponin reaction, and the flow rate is 3 ml / min per kilogram of medicinal materials. Control the upper and lower flow rates to be equal, and the column cannot be dried;

[0104] C. When the vacuum degree is 0.04Mpa and the temperature is 50-55°C, the percolation liquid is concentrated under reduced pressure, and ethanol is recovered. The concentrated liquid has no alcohol smell, and the relative density is 1.06-1.12;

[0105] D. Add water to 3 times the amount of the percolation liquid after being concentrated to no alcohol smell, centrifuge, take the clear liquid and put it on the column, the dropping speed is 3 ml / min pe...

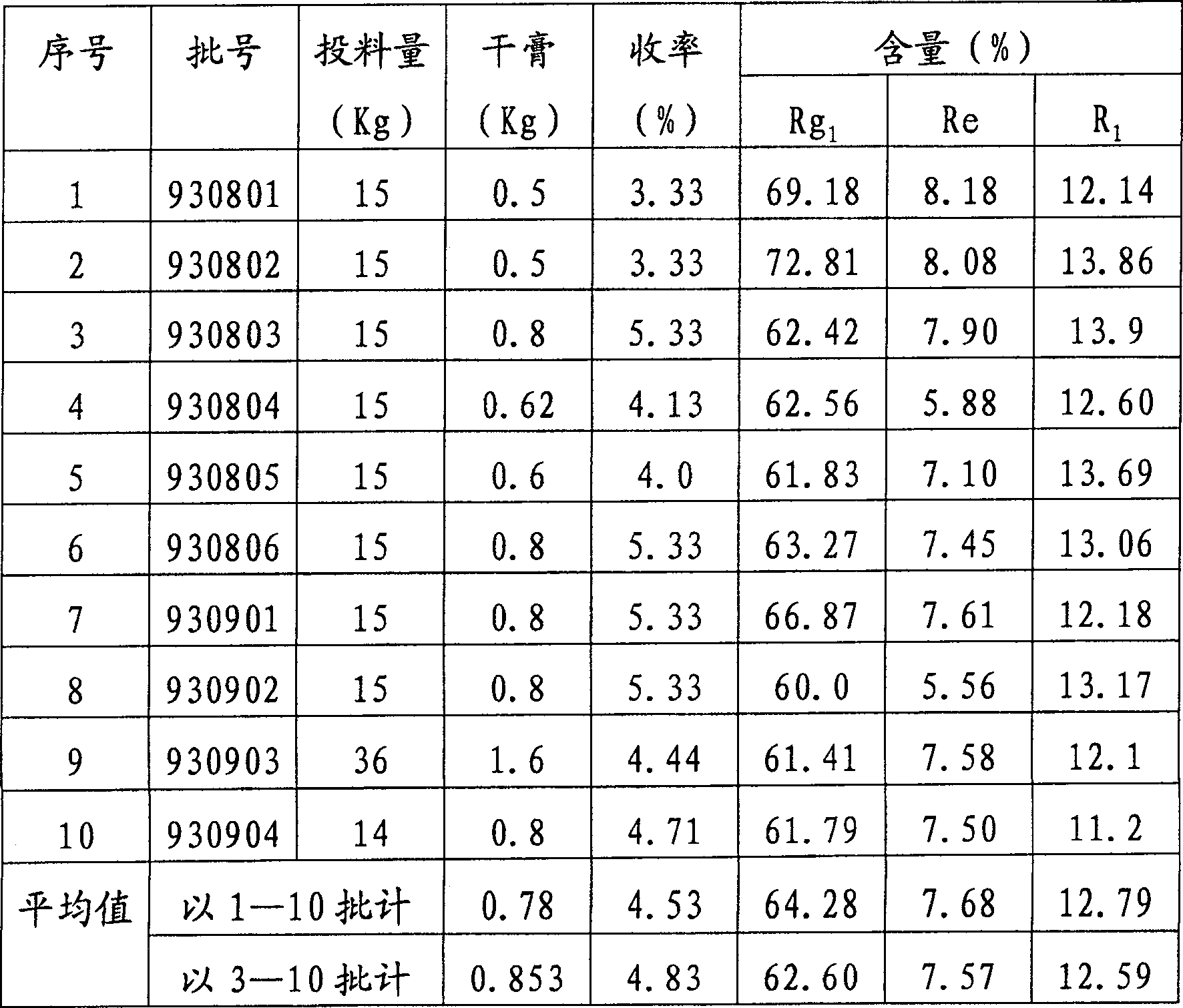

example 3

[0108] Example 3: Prepare notoginseng triol saponin according to the following steps:

[0109] A. Take notoginseng and crush it through No. 1 sieve, add 90% ethanol to soak for 28 hours, then evenly compact and fill it into the percolation bucket;

[0110] B. Percolation of 60% ethanol with 12 times the amount of medicinal materials until the effluent has no saponin reaction, the flow rate is 7 ml / min per kilogram of medicinal materials, the soaking liquid flows out to the full liquid level when percolating, and then 60% ethanol is added dropwise, Control the upper and lower flow rates to be equal, and the column cannot be dried;

[0111]C. When the vacuum degree is 0.08Mpa and the temperature is 50-55°C, the percolation liquid is concentrated under reduced pressure, and ethanol is recovered. The concentrated liquid has no alcohol smell, and the relative density is 1.06-1.12;

[0112] D. Add water to 6 times the amount of the percolation liquid after being concentrated to no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com