Radiant stand, radiant polyurethane coating material and their production

A polyurethane coating and radioactive technology, which is applied in the field of preparation of radioactive stents, can solve problems such as restenosis of esophagus and other lumens, and achieve the effects of easy activity, easy protection, and simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

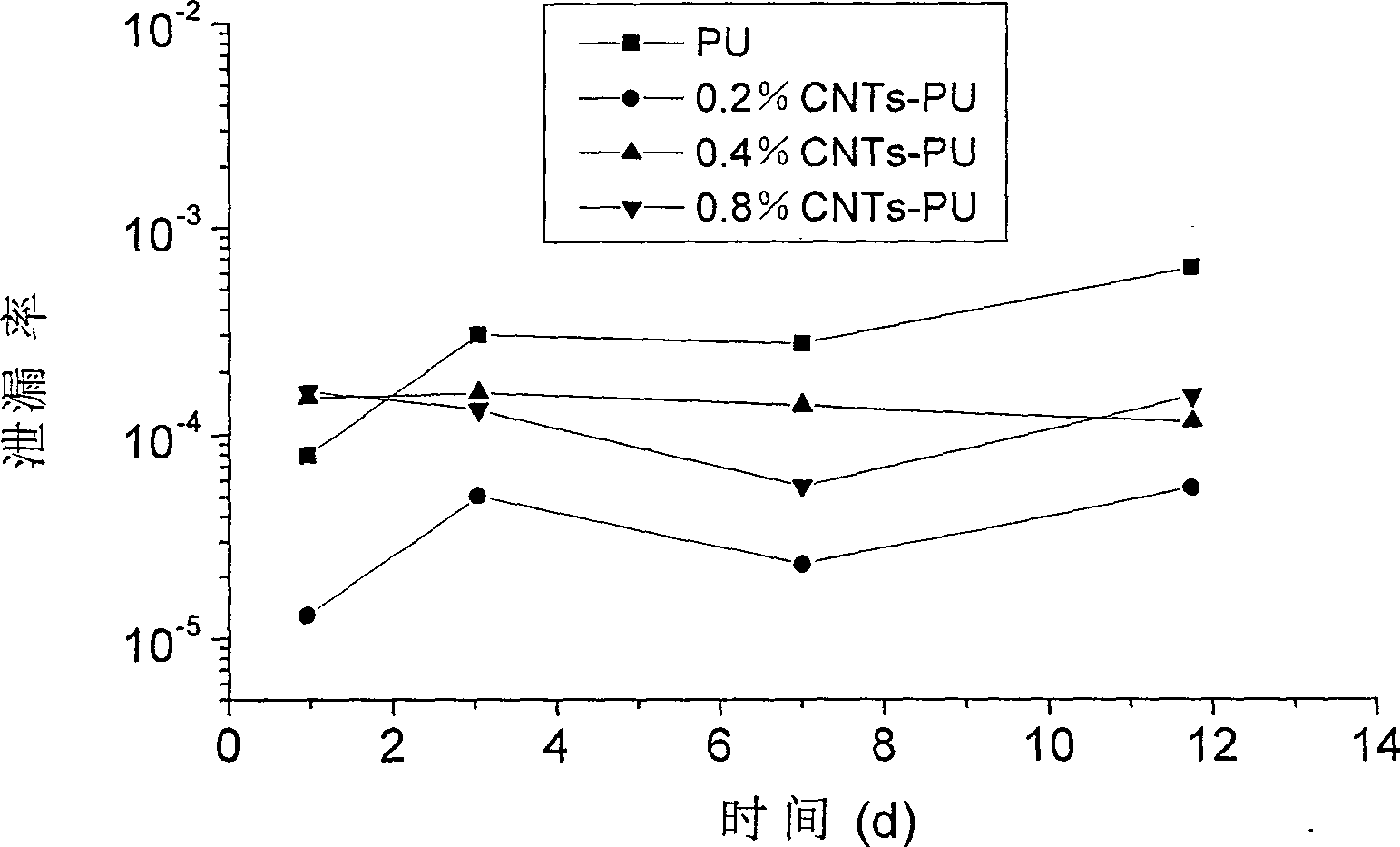

Image

Examples

Embodiment 1

[0023] Embodiment 1 Preparation of radioactive coating material

[0024] Polyurethane was dissolved in tetrahydrofuran to prepare an 8% (w / w) solution. Take medical use 32 P—sodium phosphate oral liquid, add 3 times (molar ratio) of non-radioactive Na 2 HPO 4 Solution and carbon nanotube solution, the admixture of carbon nanotube is 0.4% of polyurethane quality, adjust pH to be 9, then use CrCl 3 solution to precipitate it, CrCl 3 The number of moles of the solution is Na 2 HPO 4 2 times the solution. Centrifuge and wash with tetrahydrofuran for 4 times, and finally add these radioactive precipitates to the prepared polyurethane solution, and stir evenly to obtain the radioactive coating material.

Embodiment 2

[0025] Embodiment 2 Preparation of radioactive coating material

[0026] Polyurethane was dissolved in tetrahydrofuran to prepare a 6% (w / w) solution. Take medical use 32 P—sodium phosphate oral liquid, add 3 times (molar ratio) of non-radioactive Na 2 HPO 4 Solution and carbon nanotube solution, the doping amount of carbon nanotube is 0.2% of polyurethane quality, adjust pH to be 8, then use CrCl 3 solution to precipitate it, CrCl 3 The number of moles of the solution is Na 2 HPO 4 2 times the solution. Centrifuge and wash with tetrahydrofuran for 3 times, and finally add these radioactive precipitates to the prepared polyurethane solution, and stir evenly to obtain the radioactive coating material.

Embodiment 3

[0027] Example 3 Preparation of radioactive coating material

[0028] Polyurethane was dissolved in N,N-dimethylformamide to prepare a 5% (w / w) solution. Take medical use 32 P—sodium phosphate oral liquid, add 2 times (molar ratio) of non-radioactive Na 2 HPO 4 Solution and carbon nanotube solution, the doping amount of carbon nanotube is 0.6% of polyurethane quality, adjusts pH to be 12, then with CaCl 2 solution to precipitate it, CaCl 2 The number of moles of the solution is Na 2 HPO 4 3 times the solution. Centrifuge and wash with tetrahydrofuran for 5 times, and finally add these radioactive precipitates to the prepared polyurethane solution, and stir evenly to obtain the radioactive coating material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com