Process for preparing cellulose long-chain fatty acid ester

A long-chain fatty acid ester, cellulose technology, applied in the application field of ultrasound and microwave, can solve the problems of high price of long-chain acid chloride, difficult to popularize, large process, etc., and achieve strong reaction performance and interaction performance, and fast reaction speed. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

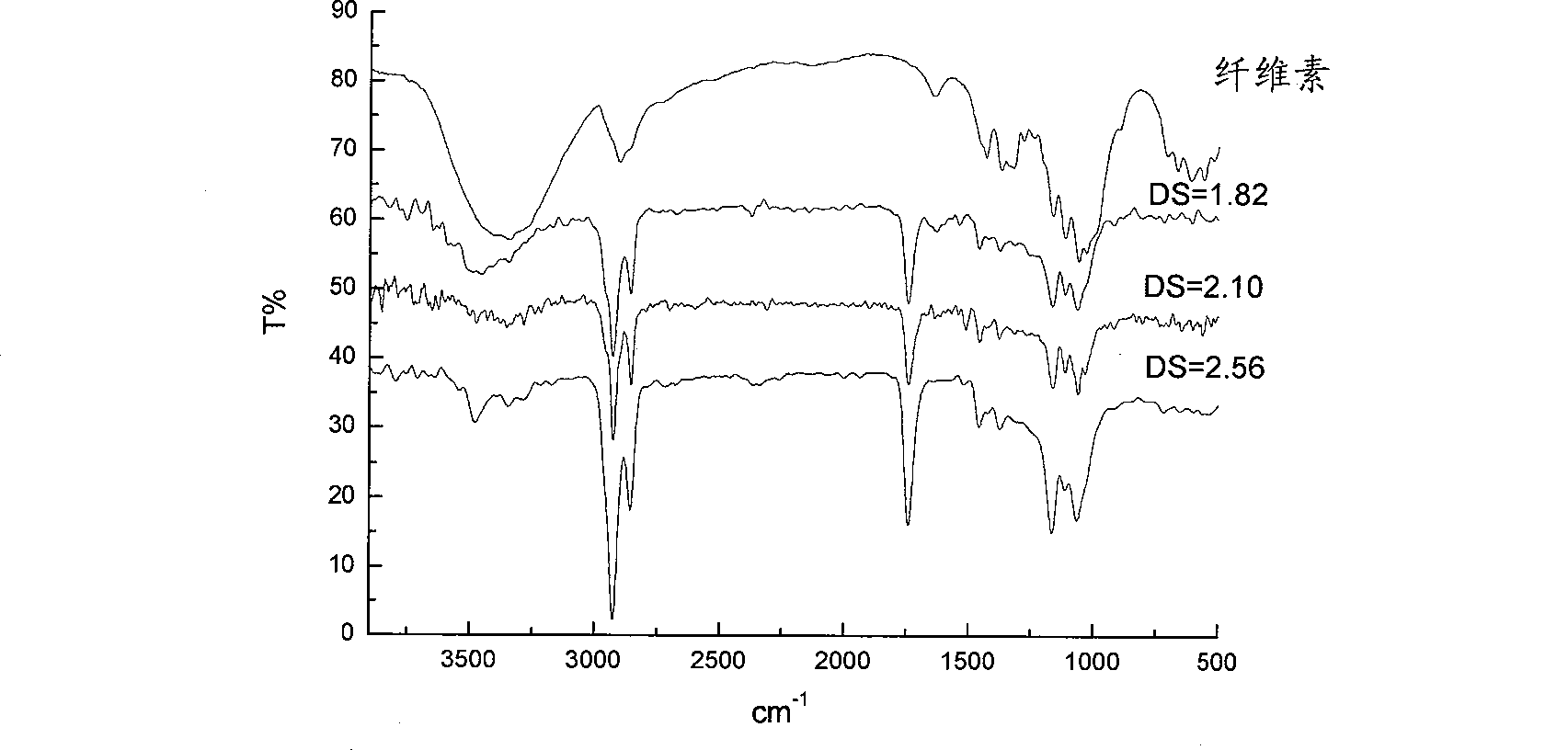

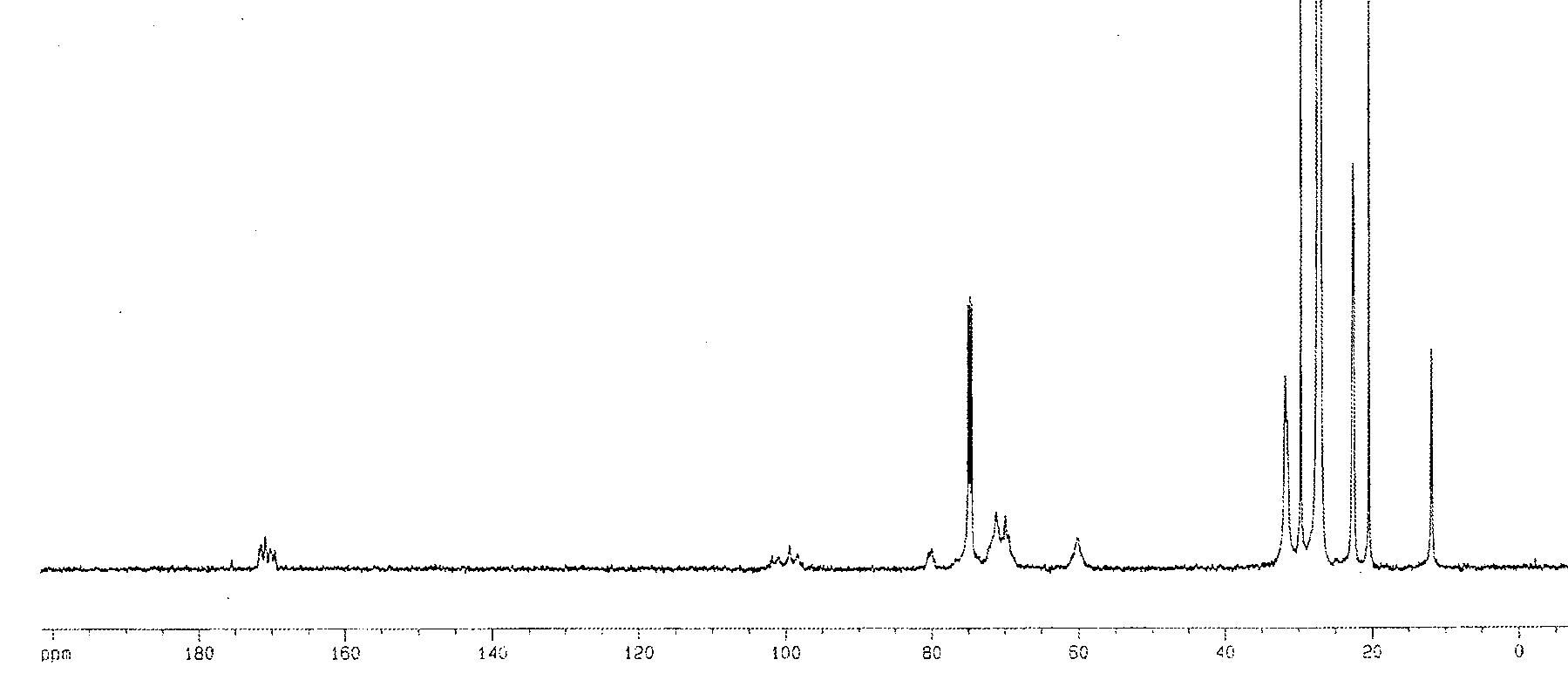

[0024] A preparation method for obtaining the above-mentioned cellulose long-chain fatty acid ester, which utilizes long-chain fatty acids and is synthesized by microwave-assisted technology, and is realized through the following steps:

[0025] a Add 2%-4% microcrystalline cellulose and 6%-9% lithium chloride into dimethylacetamide, and ultrasonicate for 5-13 minutes with a power of 400w-800w and a frequency of 20-25KHz , stirring at a speed of 250-500 / min at room temperature for 2-5 hours to obtain a colorless, transparent cellulose ion solution A;

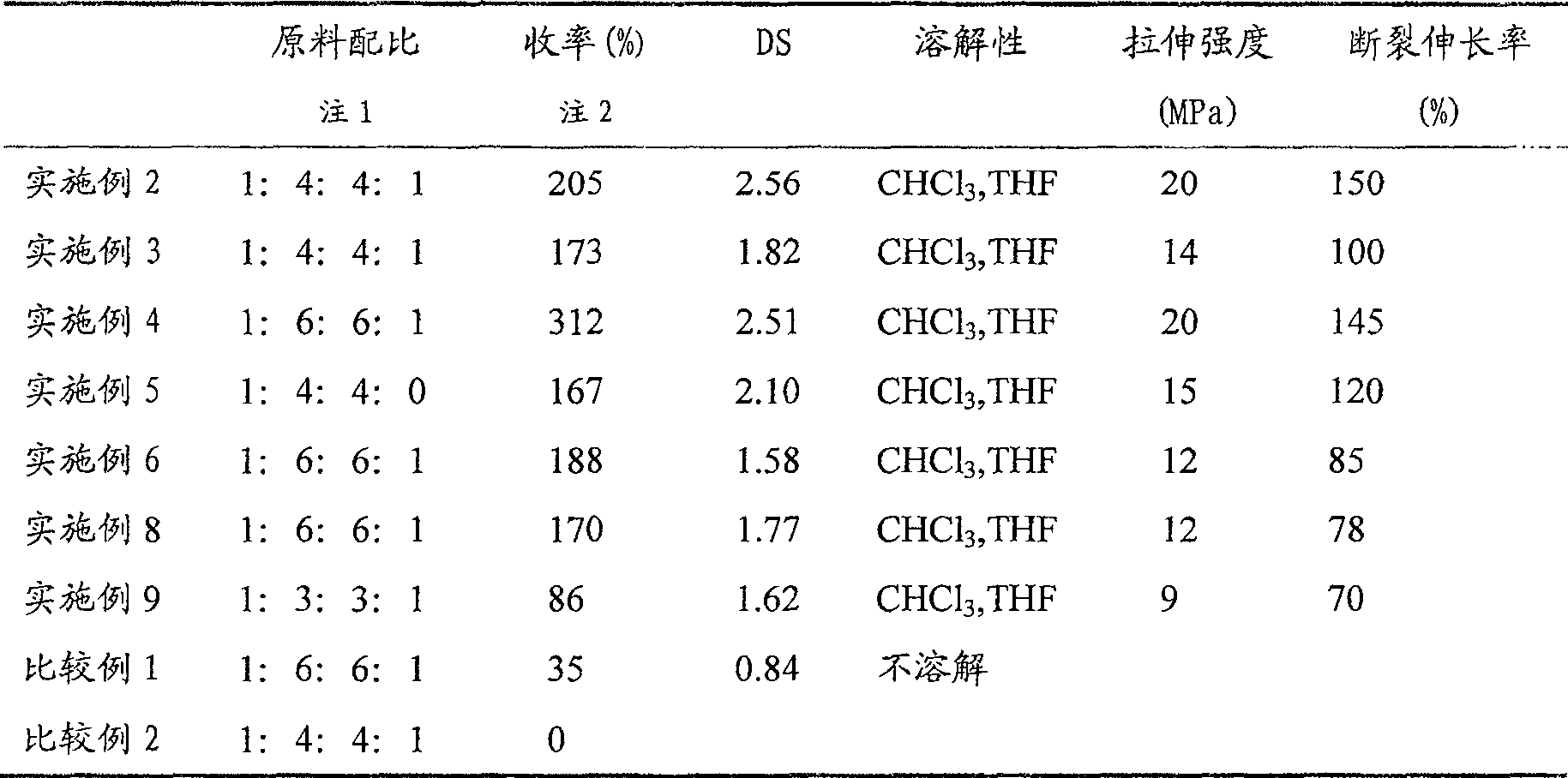

[0026] b Add cellulose, long-chain fatty acids, and co-reactants in solution A at a molar ratio of 1:2:2 to 1:6:6, and then irradiate in a microwave reactor for 60 seconds to 90 seconds with a power of 300w~400w, the frequency is 2450MHz, stirring under the protection of nitrogen at the same time, the stirring speed is 700-1500 / min, the reaction solution system is stirred by microwave for 1-3 hours, then precipitated and washed ...

Embodiment 2

[0029] Weigh 2g of microcrystalline cellulose and 8g of lithium chloride into a 150ml beaker filled with 100ml of dimethylacetamide, set the ultrasonic power at 600w and the frequency of 20KHz for 7 minutes, and then transfer it into a 250ml three-port Stir in the flask for 2 hours to obtain a transparent cellulose ion solution, add 9.46g toluene-sulfonyl chloride, 9.93g lauric acid, 1.52g p-methylaminopyridine was irradiated for 90 seconds under the conditions of microwave power 320w and frequency 2450MHz, then stirred for 3 hours, then precipitated with distilled water, filtered and washed, and then washed with NaHCO 3 The solution is washed, and the obtained cellulose laurate is vacuum-dried at 50°C for 12 hours. See the attached table for the results of the product properties.

Embodiment 3

[0031] Weigh 2g of microcrystalline cellulose and 8g of lithium chloride into a 150ml beaker filled with 100ml of dimethylacetamide, set the ultrasonic power at 400w and the frequency of 25KHz for 13 minutes, and then transfer it into a 250ml three-port Stir in the flask for 4.5 hours to obtain a transparent cellulose ion solution. Add 9.46g toluene-sulfonyl chloride, 9.93g lauric acid, and 1.52g p-toluene to this solution in a molar ratio of 1:4:4:1 to cellulose. Aminopyridine was irradiated at a microwave power of 300w for 86 seconds, followed by stirring for another 3 hours, then precipitated with distilled water, filtered and washed, followed by NaHCO 3 After washing with the solution, the obtained cellulose laurate can be vacuum-dried at 50°C for 12 hours, and the properties of the product are shown in the attached table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com