Chemical method for synthesizing palmitoyl chloride

A palmitoyl chloride and chemical synthesis technology, applied in the field of chemical synthesis of palmitoyl chloride, can solve the problems of high sealing requirements of reaction equipment, difficult handling, pollution, etc., and achieve great implementation value and social and economic benefits, advanced process route, and simple operation. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

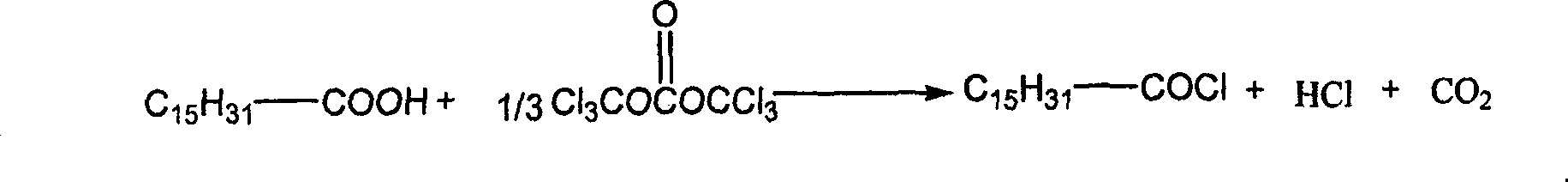

Method used

Image

Examples

Embodiment 1

[0018] The amount ratio of feed material is palmitic acid: bis (trichloromethyl) carbonate: catalyzer is 1:0.34:0.01, and catalyzer is tetramethylguanidine, and organic solvent is toluene, and its consumption is 2 times of palmitic acid quality.

[0019] In a 250mL three-neck flask equipped with a thermometer, reflux condenser and mechanical stirring, add 25.6g (100mmol) of palmitic acid, 10.1g (34mmol) of bis(trichloromethyl)carbonate, 59.5ml of toluene and 0.1g of tetramethylguanidine g (1 mmol). After the addition, heat up to 80°C and react at 80-85°C for 7 hours. After the reaction is completed, evaporate the solvent under normal pressure and distill at a vacuum of 2.3kpa to collect fractions at 190-192°C to obtain 25.4g of palmitoyl chloride, with a product yield of 92.5 %, purity 98.5%. 1 H NMR (CDCl 3 )δ: 2.8(3,2H), 1.6~1.8(m,2H), 1.2~1.4(m,24H), 0.9(3,3H).

Embodiment 2

[0021] The amount ratio of feed material is palmitic acid: two (trichloromethyl) carbonates: catalyst is 1:0.7:0.01, and palmitic acid charging capacity is 25.6g (100mmol), two (trichloromethyl) carbonate charging capacity is 20.5 g (70mmol), the catalyst is 1,3-dimethyl-2-imidazolidinone, and its consumption is 0.1g (1mmol), and the organic solvent is toluene, and its consumption is 2 times of palmitic acid quality.

[0022] The reaction temperature was 80-85° C., and other operations were the same as in Example 1 to obtain 25.1 g of palmitoyl chloride with a product yield of 91.5% and a purity of 99.0%. 1 H NMR (CDCl 3 )δ: 2.8(3,2H), 1.6~1.8(m,2H), 1.2~1.4(m,24H), 0.9(3,3H).

Embodiment 3

[0024] The amount ratio of the feed material is palmitic acid: two (trichloromethyl) carbonates: the catalyst is 1:1:0.02, the amount of palmitic acid is 25.6g (100mmol), and the amount of bis(trichloromethyl) carbonates is 29.7 g (100mmol), the catalyst is pyridine, and its consumption is 0.2g (2mmol), and the organic solvent is tetrahydrofuran, and its consumption is 2 times of palmitic acid quality.

[0025] The reaction temperature was 60-65° C., and other operations were the same as in Example 1 to obtain 26.1 g of palmitoyl chloride with a product yield of 95.0% and a purity of 99.0%. 1 H NMR (CDCl 3 )δ: 2.8(3,2H), 1.6~1.8(m,2H), 1.2~1.4(m,24H), 0.9(3,3H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com