Glucokinase preparing process

A technology of staphylokinase and enterokinase, which is applied in the field of bioengineering pharmaceuticals, can solve the problems of high cost, long production cycle, and can not be used for it, and achieve the effect of low pyrogen, low cost, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

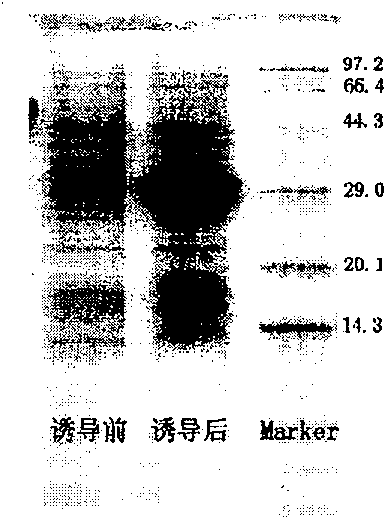

[0049] [Example 1] Construction of engineering bacteria and expression of fusion protein

[0050] With the patent application publication number being CN1807603A engineering bacterium complete DNA as template, with primer 1, 2 as doing PCR amplification (primer 1:

[0051] 5'-AAAGGTACCGACGACGACGACAAGTCAAGTTCATTCGACAAAGGA-3'

[0052] Primer 2: 5'-AAAGAGCTCTCATTATTTTCTTTCTATAACAACCTT-3', primer 1 contains the KpnI site, primer 2 contains the SacI site) to obtain a fusion protein gene containing staphylokinase such as SEQ NO.1, after the obtained gene is sequenced and analyzed, cloned On the pET32(a) vector, the insertion site is KpnI / SacI, and the plasmid pET32(a) / Sak is constructed. The specific construction is shown in Figure 3.

[0053] The sequencing results are as follows: GGT ACC GAC GAC GAC GAC AAG TCA AGT TCA TTCGAC AAA GGA AAA TAT AAA AAA GGC GAT GAC GCG AGT TAT TTT GAACCA ACA GGC CCG TAT TTG ATG GTA AAT GTG ACT GGA GTT GAT GGTAAA GGA AAT GAA TTG CTA TCC CCT CAT TAT ...

Embodiment 2

[0056] [Example 2] Preparation of Staphylokinase

[0057] 1. Materials and equipment

[0058] Bacteria-breaking tools: homogenizer;

[0059] SDS-PAGE electrophoresis scanner: DS-700Bio-Rad;

[0060] Chromatography column: 50×300mm, 100×300mm Shanghai Yarong Biochemical Instrument Factory;

[0061] Chromatography medium: Chelating-Sepharose Fast Flow and Q-Sepharose Fast Flow are both products of Pharmacia Biotech, and the particle diameter is 90 μm.

[0062] Chromatographic detection system: UV detector (HD-93-1 type) Shanghai Jinda Biochemical Instrument Factory.

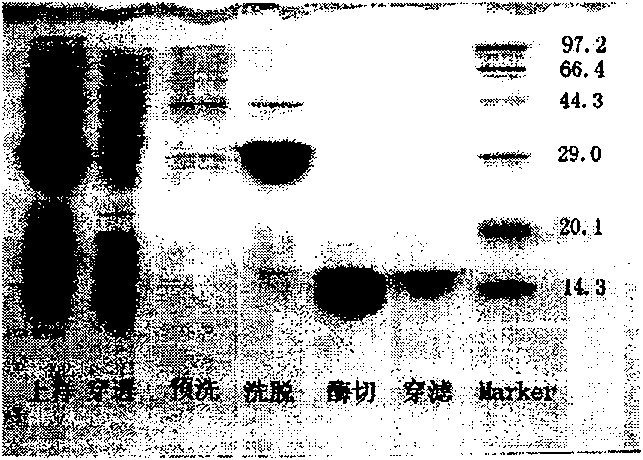

[0063] 2. Preparation process

[0064] 1) Broken engineering bacteria

[0065] Get the engineering bacteria with a wet weight of 500g from the fermentation, suspend the bacteria with 2500ml pH8.0 10mM phosphate buffer, break the bacteria, centrifuge to obtain 2300ml of supernatant, filter through 0.45 μm, put on a metal chelation column to extract the fusion protein, and The sequence is shown in SEQ NO.2.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com