Medicine-loading sustained-release micro-capsule and preparing method thereof

A slow-release microcapsule and drug-carrying technology, which is used in pharmaceutical formulations, drug delivery, and non-active ingredients medical preparations, etc. Biocompatibility, good physical and chemical properties, smooth drug release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

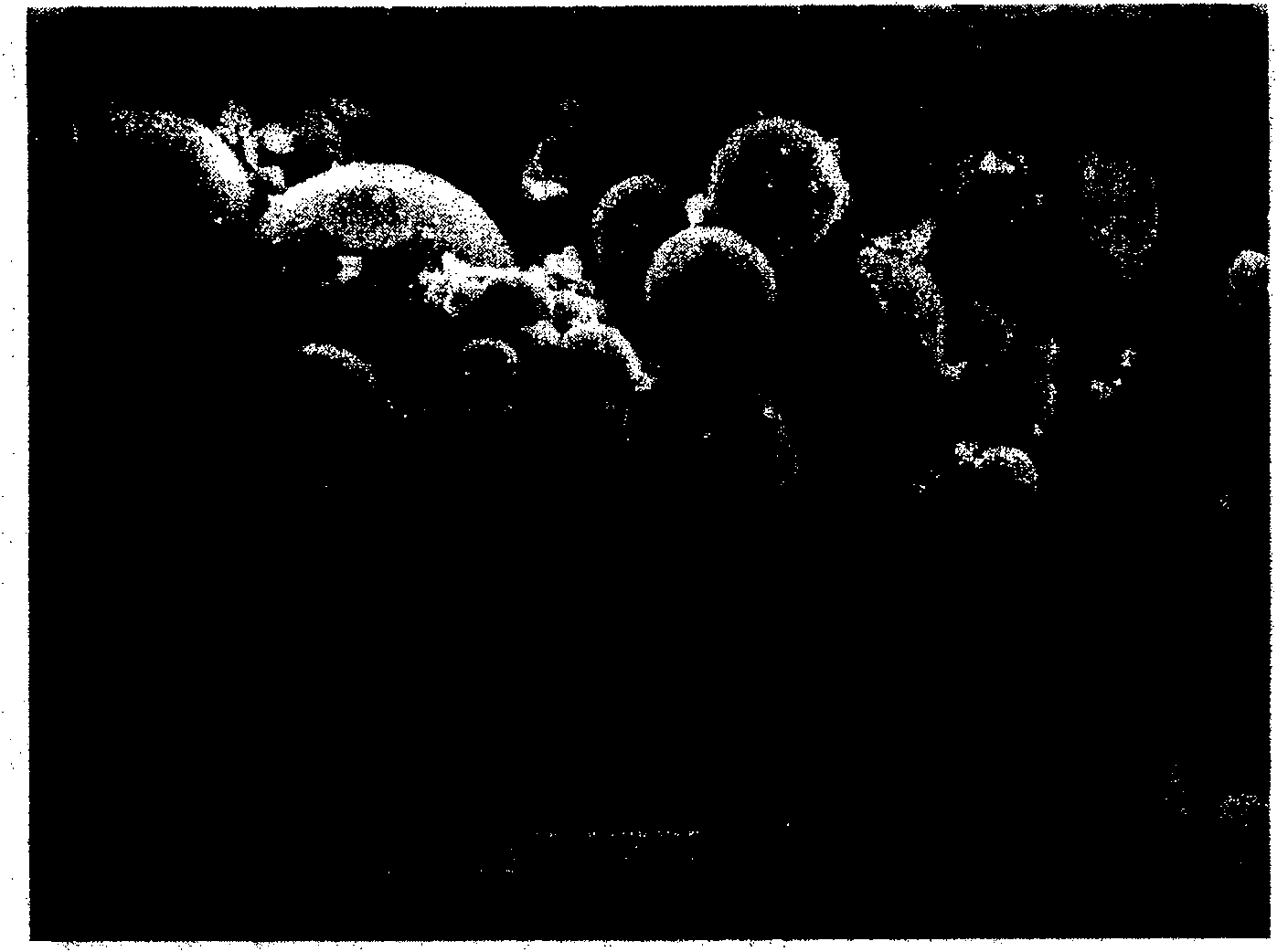

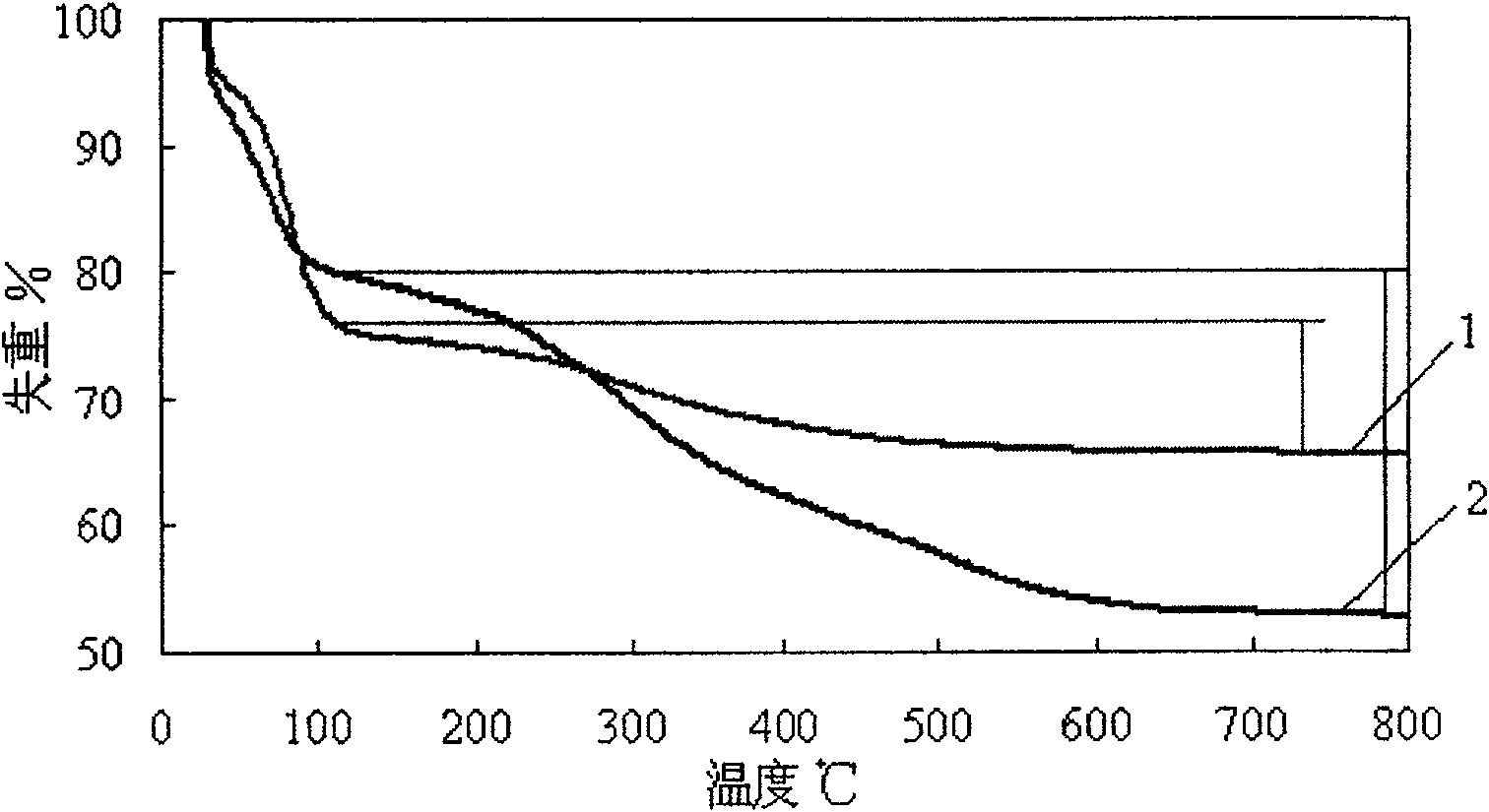

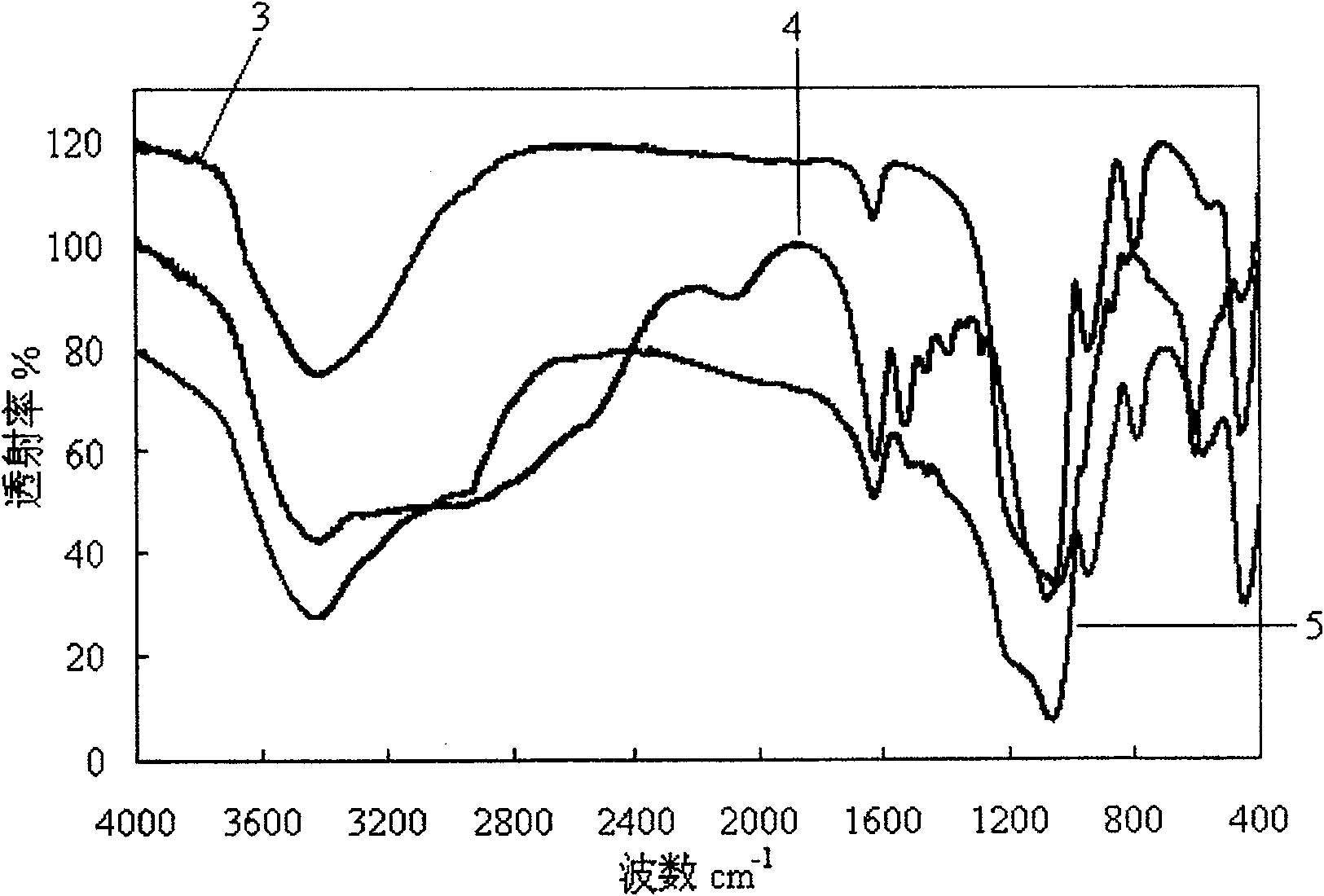

[0035] Embodiment 1: 0.2g drug gentamicin sulfate is dissolved in 2ml mass fraction and is 6% hydrochloric acid, and adds 0.04g water-soluble surfactant polyoxyethylene sorbitan monooleate, mixes uniformly to form drug- Aqueous solution A of surfactant-precipitating agent, wherein the drug concentration is about 100mg / ml, and the concentration of water-soluble surfactant is about 0.02g / ml; add 2.0g of oil-soluble surfactant sorbitan monooleate to 50ml In the water-insoluble non-polar oil solvent cyclohexane, mix uniformly to form a surfactant-oil solvent solution B, wherein the concentration of the oil-soluble surfactant is about 0.04g / ml; under stirring conditions, the solution A Slowly add in solution B, the volume ratio of solution A and solution B is 1:25, keep stirring until a stable water / oil type emulsion C is formed; 25% of the mass), and continued to stir for 24 hours, so that the silicon source material was fully hydrolyzed and polycondensed, and a silica coating lay...

Embodiment 2

[0036] Embodiment 2: Add 0.4g drug gentamycin sulfate and 0.04g water-soluble surfactant polyoxyethylene sorbitan monooleate to 2ml mass fraction of 6% hydrochloric acid, mix uniformly to form drug-surfactant Aqueous solution A of agent-precipitating agent, wherein drug concentration is about 200mg / ml, and water-soluble surfactant concentration is about 0.02g / ml; In 50ml of water-insoluble non-polar oil solvent cyclohexane, mix uniformly to form surfactant-oil solvent solution B, wherein the concentration of oil-soluble surfactant is about 0.04g / ml; under stirring conditions, the solution A is slowly added to solution B, the volume ratio of solution A to solution B is 1:25, and the stirring is continued until a stable water / oil emulsion C is formed; 2ml of tetraethyl orthosilicate, a silicon source material, is added to emulsion C (according to aqueous solution 25% of the mass of A), and continued to stir for 30 hours, so that the silicon source material was fully hydrolyzed a...

Embodiment 3

[0037] Embodiment 3: 0.2g drug salbutamol sulfate is dissolved in 2ml mass fraction and be in the hydrochloric acid of 6%, and add 0.04g water-soluble surfactant polyoxyethylene sorbitan monooleate, mix uniformly to form drug-surfactant Aqueous solution A of agent-precipitating agent, wherein drug concentration is about 100mg / ml, water-soluble surfactant concentration is about 0.02g / ml; 2.0g oil-soluble surfactant sorbitan monooleate is added into 50ml insoluble In the non-polar oil solvent cyclohexane of water, mix evenly to form a surfactant-oil solvent solution B, in which the concentration of oil-soluble surfactant is about 0.04g / ml; under stirring conditions, slowly add solution A In solution B, the volume ratio of solution A to solution B is 1:25, and the stirring is continued until a stable water / oil emulsion C is formed; 25% meter), and continue to stir for 24 hours, so that the silicon source material is fully hydrolyzed and polycondensed, and a silica coating layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com