Ammonii chloridum caking-proof agent and its application in preparation of caking-proof ammonii chloridum

An anti-caking agent, ammonium chloride technology, applied in the direction of ammonium halide and other directions, can solve the problems of growth and improvement of fertilizer utilization rate and protection of soil environment without any promoting effect, difficult to degrade, secondary pollution, etc., and achieve the use method. Simple and practical, saving fertilizer and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

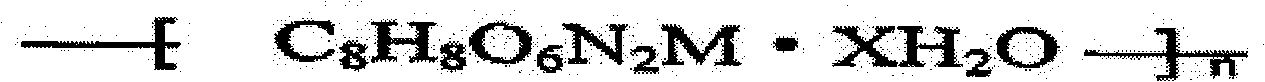

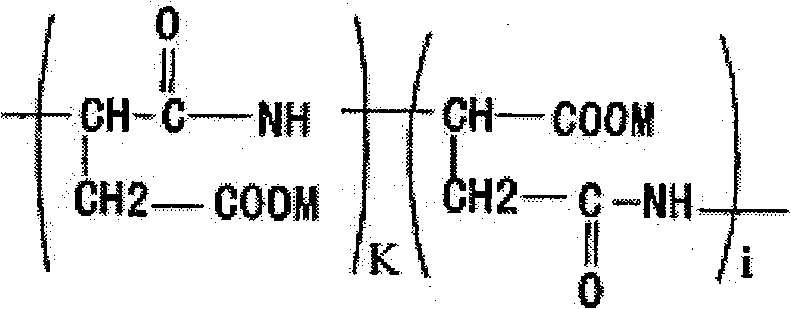

[0028] Synthesis of aspartic acid polymer

[0029] M is Na: add polysuccinimide (ie PSl) to a certain amount of water, then add an equimolar amount of solid NaOH to hydrolyze for half an hour, and dry to obtain sodium polyaspartate.

[0030] M is K: the same synthesis method as M is Na, but KOH is used instead of NaOH.

[0031] M is for NH 4 Synthesis of: the same as the synthesis of M for Na, just use NH 4 OH instead of NaOH.

[0032] Physicochemical performance parameters of aspartic acid polymer:

[0033] 1. State: amber liquid

[0034] 2. Polymer molecular weight: M: 2000-8000

[0035] 3. Density (20°C) g / cm: ≥1.05-1.22

[0036] 4. pH: 6.0-10.0

[0037] 1. Biodegradability: ≥65% for 30 days

Embodiment 2

[0039] Mn-SOD, Cu, Zn-SOD were synthesized according to the method disclosed in CN1803812A.

[0040] Physicochemical parameters of simulated SOD compounds:

[0041] 1. State: amber liquid

[0042] 2. SODm enzyme specific activity: ≥4000IU / mg

[0043] 3. Molecular weight: 1000-3000

[0044] 6. pH value (1% aqueous solution): 8.0-10.5

[0045] 7. Density (20°C): 1.2g / cm3

[0046] 8. Biodegradability: ≥65% / 30 days

[0047] 9. Heat resistance temperature: 180°C

Embodiment 3

[0049] Mix 1 kg of SODm (wherein n is 5, M is manganese) and 1000 kg of aspartic acid polymer (wherein z is 15, M is potassium) to obtain ammonium chloride anti-caking agent 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com