Array type ultra-thin submissive force sensor and preparation method thereof

An array type sensor technology, applied in the field of force sensors, to achieve linear output, reduce the number of gating switches, high force sensitivity accuracy and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

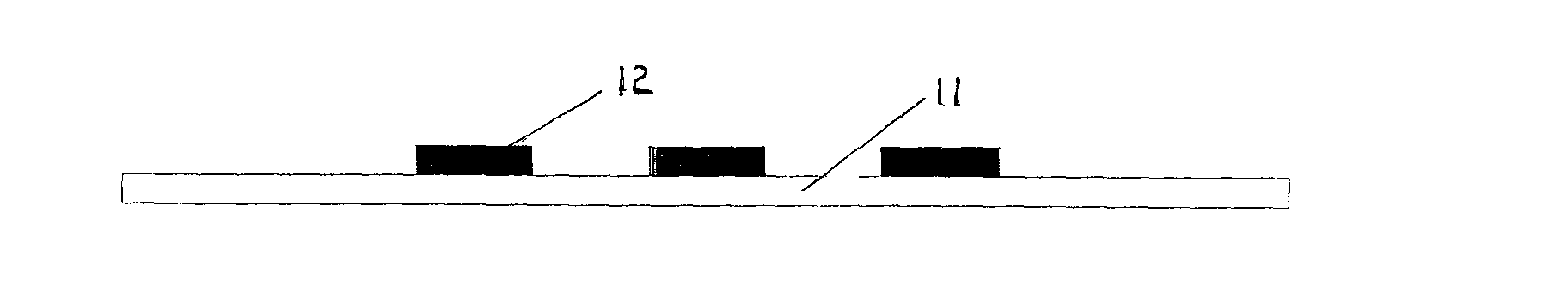

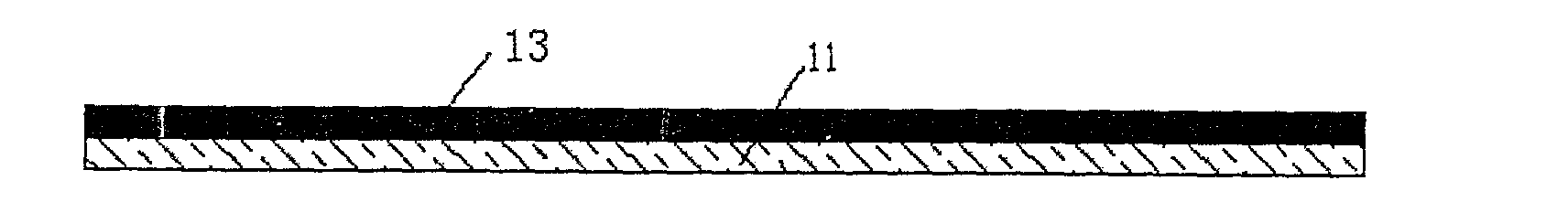

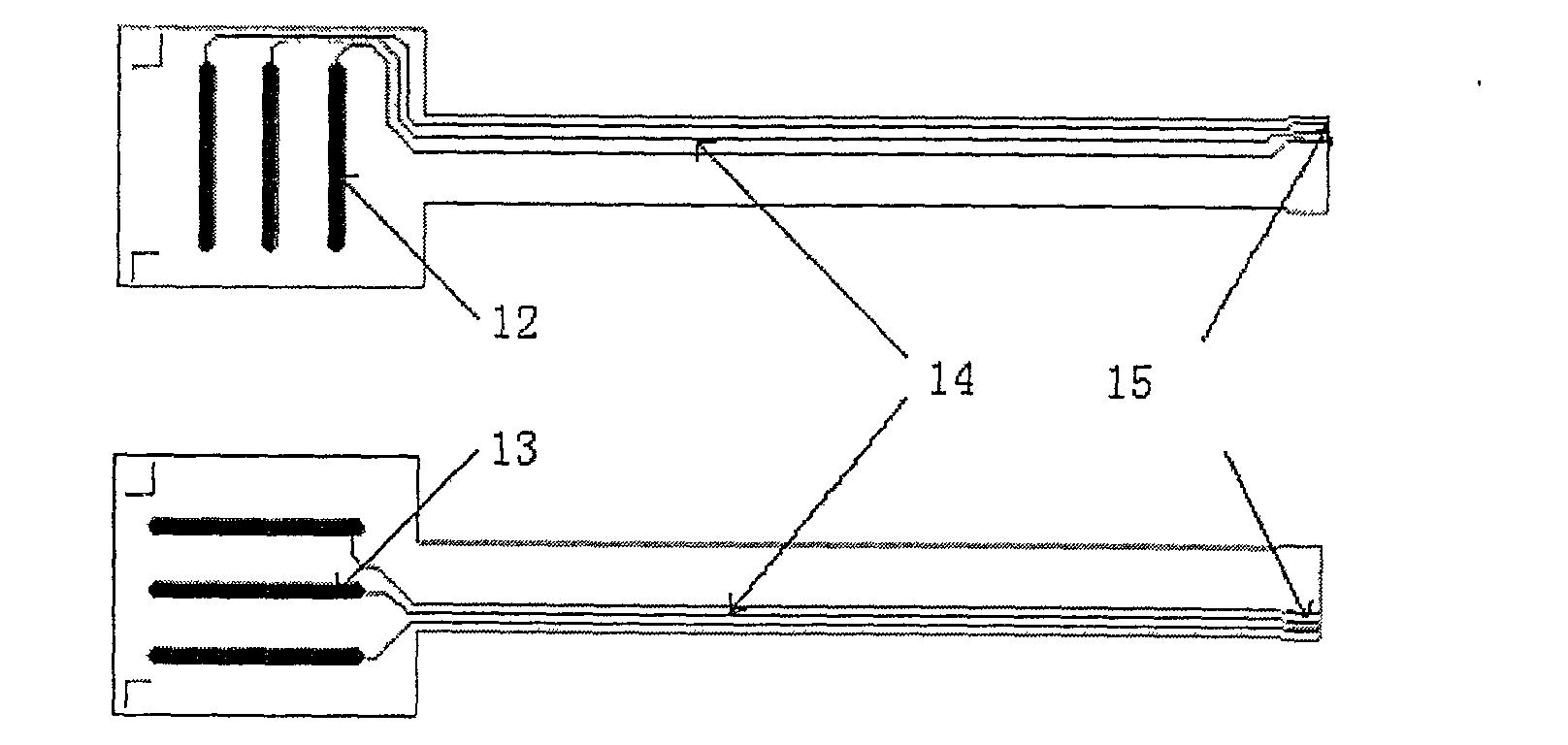

[0063] The preparation method of the array-type ultra-thin compliant force sensor proposed by the present invention includes two parts: the preparation of an ultra-thin compliant conductive polymer sensitive film and the preparation of an array-type compliant force sensor using the sensitive film. The ultra-thin compliant conductive polymer is sensitive The preparation of membrane comprises the following steps:

[0064] 11) Conductive carbon black powder with an average diameter of less than 1 μm, SiO with a diameter of 10-50 nm 2 Dispersant powder and liquid one-component silicone rubber are mixed in acetone organic solvent with a concentration of more than 95%; wherein, the volume concentration percentage of each component is: one-component silicone rubber: conductive carbon black powder: nano-SiO 2 Dispersant powder: acetone organic solvent = 100:10~15:1~3:300~500;

[0065] 12) Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environm...

Embodiment 1

[0079] 11) Conductive carbon black powder with an average diameter of less than 1 μm, SiO with a diameter of 10 nm 2 Dispersant powder and liquid one-component silicone rubber are mixed in acetone organic solvent with a concentration of more than 95%; wherein, the volume concentration percentage of each component is: one-component silicone rubber: conductive carbon black powder: nano-SiO 2 Dispersant powder: acetone organic solvent=100:10:1:300;

[0080] 12) Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environment is 40°C, and the stirring time is 2 hours, until the mixture is in a gel state;

[0081] 13) Add 3% butadiene rubber particles (10 μm) of the total volume of the mixture into the mixture, and continue mechanical stirring for 20 minutes to volatilize the acetone;

[0082] 14) Drop the volatilized mixture into the rotating platform, and spin-coat to form a conductive polymer film with a thickness of 70 μm;

[0083] 15) Vulca...

Embodiment 2

[0085] 11) Conductive carbon black powder with an average diameter of less than 1 μm, SiO of 50 nm 2 Dispersant powder and liquid one-component silicone rubber are mixed in acetone organic solvent with a concentration of more than 95%; wherein, the volume concentration percentage of each component is: one-component silicone rubber: conductive carbon black powder: nano-SiO 2 Dispersant powder: acetone organic solvent=100:15:3:500;

[0086] 12) Perform mechanical stirring under ultrasonic vibration, the temperature of the stirring environment is 60°C, and the stirring time is 4 hours, until the mixture is in a gel state;

[0087] 13) Add 5% butadiene rubber particles (30 μm) of the total volume of the mixture into the mixture, and continue mechanical stirring for 30 minutes to volatilize the acetone;

[0088] 14) Drop the volatilized mixture into the rotating platform, and spin-coat to form a conductive polymer film with a thickness of 100 μm;

[0089] 15) Vulcanize the conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com