Technology for extracting dihydrogalanthamine from lycoris radiata genus plant

A technology of Amaryllis genus plants and process steps, applied in the direction of drug combination, muscular system diseases, neuromuscular system diseases, etc., can solve problems such as not seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

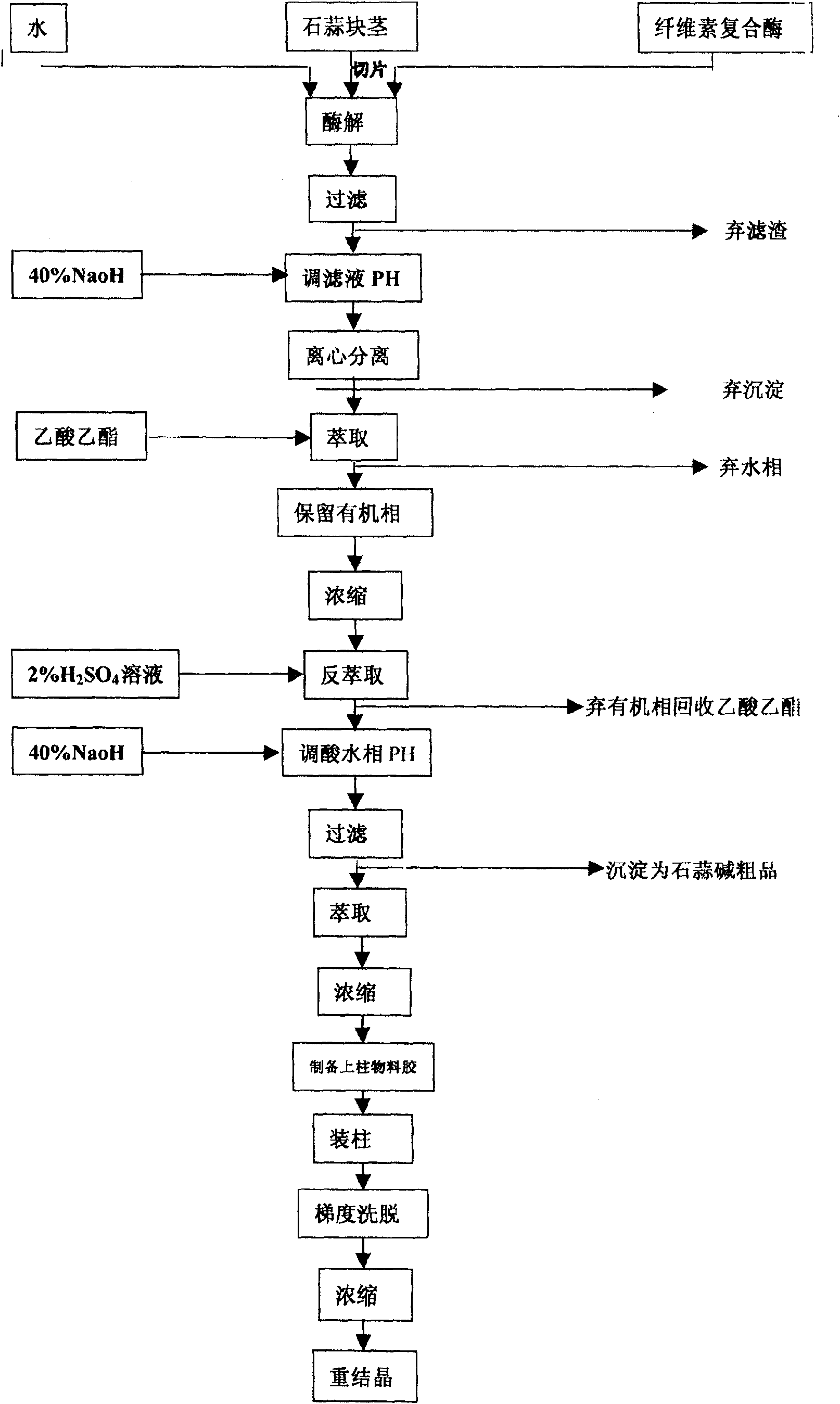

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: get 200Kg cleaned fresh amaryllis bulb slices, soak in the multifunctional extraction tank, add 1.3L liquid cellulase (enzyme activity is not less than 2000u / ml), add 800Kg water again, at a temperature of 55 ℃, PH=5, enzymatic hydrolysis for 6 hours. After the enzymolysis is completed, filter and discard the filter residue (the filter residue can be used as fertilizer) to obtain 900Kg of filtrate, and adjust the pH of the enzymolysis solution to 9-10 with 40% aqueous sodium hydroxide solution until the enzymolysis solution becomes turbid. Use the GQ75 high-speed tubular separator to centrifugally separate and remove the slag (the slag is used as fertilizer) to obtain 880Kg of centrifugate, get the centrifugate, and use 2540L ethyl acetate to extract on average in 6 times, and the extraction operation is carried out in the extraction tower for continuous extraction. Organic phase, discarding water phase, waste water phase can be discharged to sedimentation...

Embodiment 2

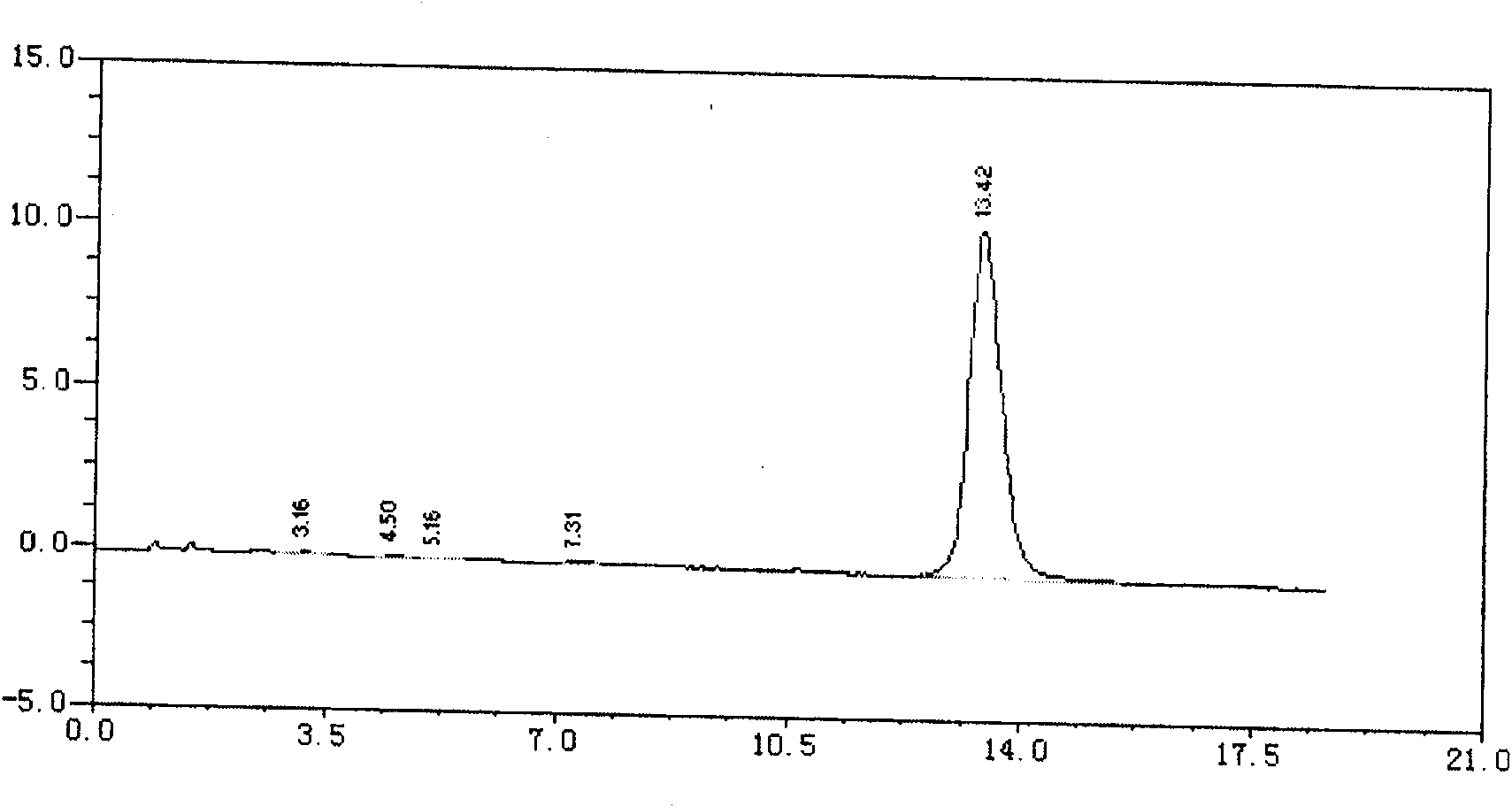

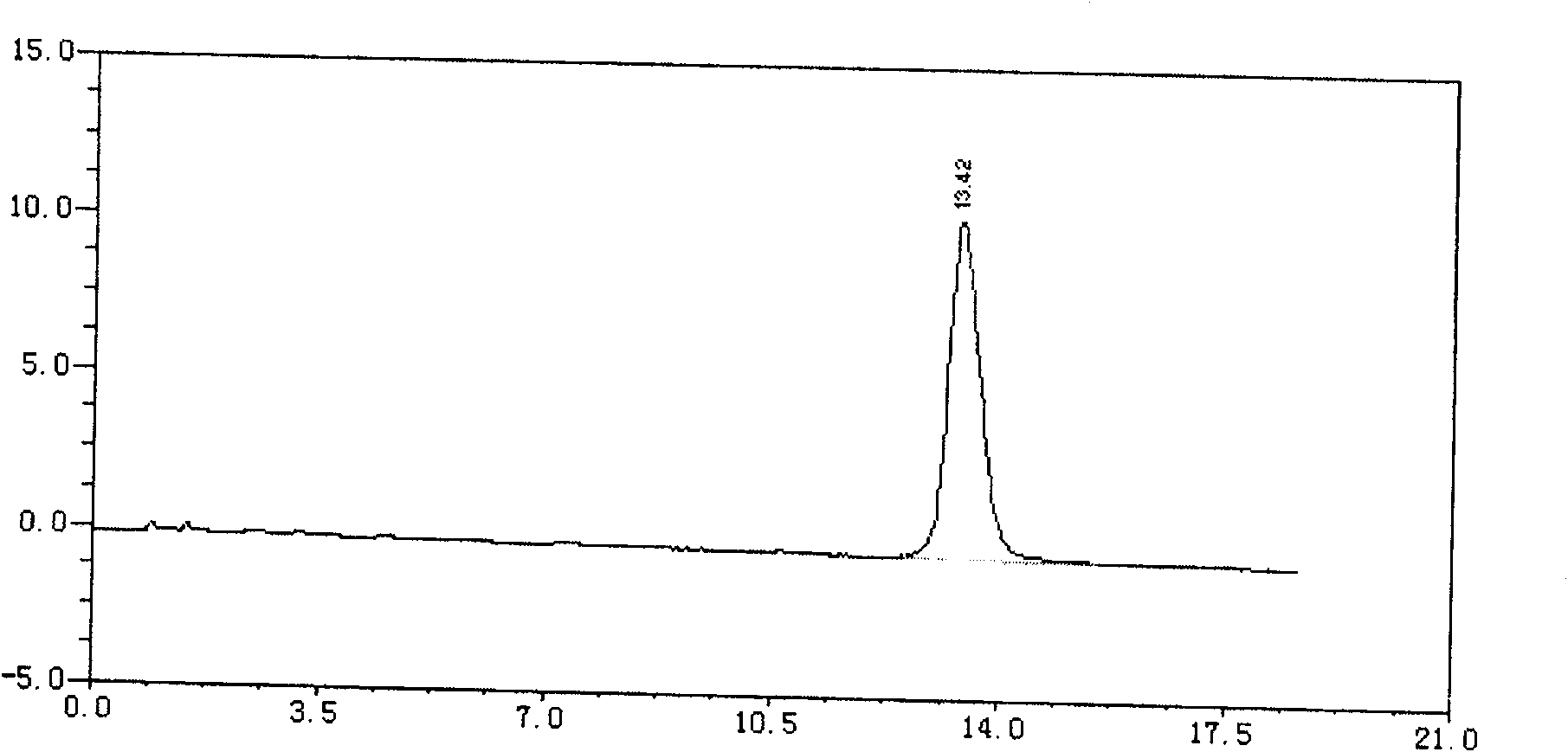

[0055] Embodiment 2: get the 115g extractum of lycoris through pre-processing gained, after analyzing the content of lycopene is 40%, galantamine 58%, in the aluminum oxide (ratio is 1: 1.2, Granularity 180-200 mesh) grind and mix evenly, add water to be 6% of the weight of alumina, mix well, make the upper column material, take 1725g of basic alumina whose activity level is III grade 7 times the weight and add 6% of the weight of alumina Mix well with water (ratio: 1:7, particle size 180-200 mesh) and put it into a chromatography column (alumina particle size: 180-200 mesh, φ is 8cm, length 82cm), beat and compact it and load it into the upper column material, compact Finally, cover the top with a layer of quartz sand with a thickness of about 0.5cm (or replace it with a piece of filter paper slightly smaller than the diameter of the column) and then use the eluent to elute. Analysis and follow-up detection, collecting the eluent containing Licolamin, evaporated to dryness at...

Embodiment 3

[0056] Embodiment 3: get the 115g extract of lycoris through pre-processing gains, grind and mix with 138g basic alumina of activity level III (ratio is 1: 1.2, particle size 180-200 mesh), add alumina weight 6% Mix well with water to make the upper column material, take 7 times the weight of basic alumina 1725g with activity level III and add 6% water of alumina weight and mix thoroughly, (ratio is 1: 7, particle size 180-200 mesh ) into a chromatographic column (alumina particle size: 180-200 mesh, φ is 8cm, length 82cm), beating and compacting and loading the upper column material, and covering the top with a layer of quartz sand (or Use a piece of filter paper slightly smaller than the diameter of the column instead) and then use the eluent to elute. The eluent formula is ether-methanol-ammonia (100:10:0.5), and the eluent is tracked and detected by thin-layer chromatography. Collect the eluate containing delicolamine and evaporate to dryness at 65°C under reduced pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com