High performance aqueous emulsion of cypermethrin, and its preparing method

A high-efficiency cypermethrin, water emulsion technology, applied in the fields of botanical equipment and methods, insecticides, biocides, etc., can solve the problems of lax management, poisoning, phytotoxicity, etc., achieve obvious social benefits, reduce the use of agricultural costs, The effect of promoting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Raw material formula:

[0035] Beta-cypermethrin 1kg, solvent xylene or toluene 1kg, emulsifier polyoxyethylene alkylphenol 0.5kg, thickener polyvinyl alcohol or xanthan gum 0.5kg, antifreeze agent ethylene glycol or propylene glycol 0.5kg, defoamer silicone 0.1kg, the remaining water 96.4kg.

[0036] Preparation:

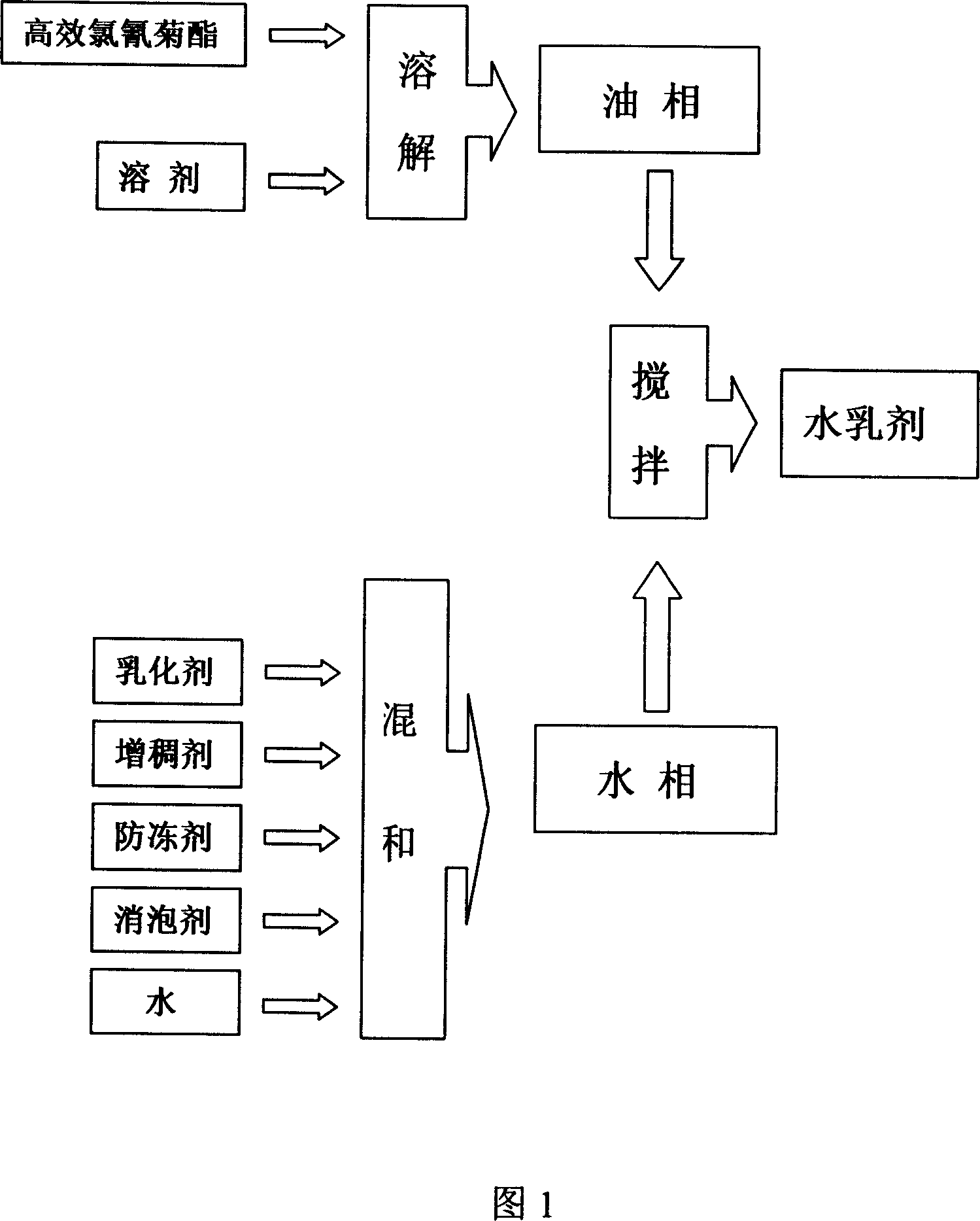

[0037] a. Add the active drug of beta-cypermethrin to the organic solvent xylene or toluene, and keep stirring until the beta-cypermethrin is completely dissolved, and use it as an oil phase for standby;

[0038] b. According to the above formula, add emulsifier, thickener, antifreeze and defoamer into the water in turn under stirring, and keep stirring until it completely dissolves into a uniform liquid, and use it as the water phase for later use;

[0039] c. First add the oil phase to the container of the shearing machine, start stirring, then gradually add the water phase to the oil phase under stirring, the speed is controlled at 1000 rpm, and stir fo...

Embodiment 2

[0041] Raw material formula:

[0042] Beta-cypermethrin 10kg, solvent xylene or toluene 5kg, emulsifier polyoxyethylene alkylarylphenol 8kg, thickener polyvinyl alcohol or xanthan gum 5kg, antifreeze agent ethylene glycol or propylene glycol 5kg, defoamer silicone 0.5kg , Surplus water 66.5kg.

[0043] Preparation:

[0044] a. Add the active drug of beta-cypermethrin to the organic solvent xylene or toluene, and keep stirring until the beta-cypermethrin is completely dissolved, and use it as an oil phase for standby;

[0045] b. According to the above formula, add emulsifier, thickener, antifreeze and defoamer into the water in turn under stirring, and keep stirring until it completely dissolves into a uniform liquid, and use it as the water phase for later use;

[0046] c. First add the oil phase to the container of the shearing machine, start stirring, then gradually add the water phase to the oil phase under stirring, the speed is controlled at 12000 rpm, and stir for 30 ...

Embodiment 3

[0048] Raw material formula:

[0049] Beta-cypermethrin 15kg, solvent xylene and toluene 12kg, emulsifier polyoxyethylene fatty alcohol and sorbitol ester mixture 10kg, thickener polyvinyl alcohol or xanthan gum 7.5kg, antifreeze agent ethylene glycol and propylene glycol 7.5kg, defoaming Agent silicone 0.7kg, balance water 47.3kg.

[0050] Preparation:

[0051] a. Add the active drug of beta-cypermethrin to the organic solvent xylene and toluene, and keep stirring until the beta-cypermethrin is completely dissolved, and use it as an oil phase for standby;

[0052] b. According to the above formula, add dimehypo technical, emulsifier, thickener, antifreeze and defoamer into the water in turn under stirring, and keep stirring until it completely dissolves into a uniform liquid, and use it as the water phase for later use;

[0053] c. First add the oil phase to the container of the shearing machine, start stirring, then gradually add the water phase to the oil phase under stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com