Foam-producing ecological toilet needing no water flushing

A foaming and ecological technology, applied in the field of sanitary equipment, can solve problems such as unavailable, chaotic microbial components, unstable biochemical degradation of feces and urine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Preparation of microbial agent

[0019] Purchase Aminobacteraminovorans ZL-1006 (preservation number CGMCC No. 1728), Bacillus megaterium ZL-1010 (preservation number CGMCC No. 1724), and subtilis from Beijing Zhongkelongtai Biotechnology Co., Ltd. Bacillus subtilis ZL-1007 (preservation number CGMCC No.1725), Bacillus sphaericus ZL-1008 (preservation number CGMCC No.1726) and Bacillus circulans ZL-1009 (preservation number) CGMCC No. 1727), the above-mentioned strains purchased were cultured on a slant medium.

[0020] Pick the above strains on the slant medium and inoculate them into 1 ml liquid medium (preparation of liquid medium: 10 g glucose, 1.36 g potassium dihydrogen phosphate, 2.13 g disodium hydrogen phosphate, 0.2 g magnesium sulfate heptahydrate, 0.05 g of ferrous sulfate heptahydrate, 0.1 g of calcium chloride and 2 g of ammonium sulfate, distilled water to make the volume to 1 liter, sterilize at 115 degrees Celsius for 30 minutes), shake at 35 degr...

Embodiment 2

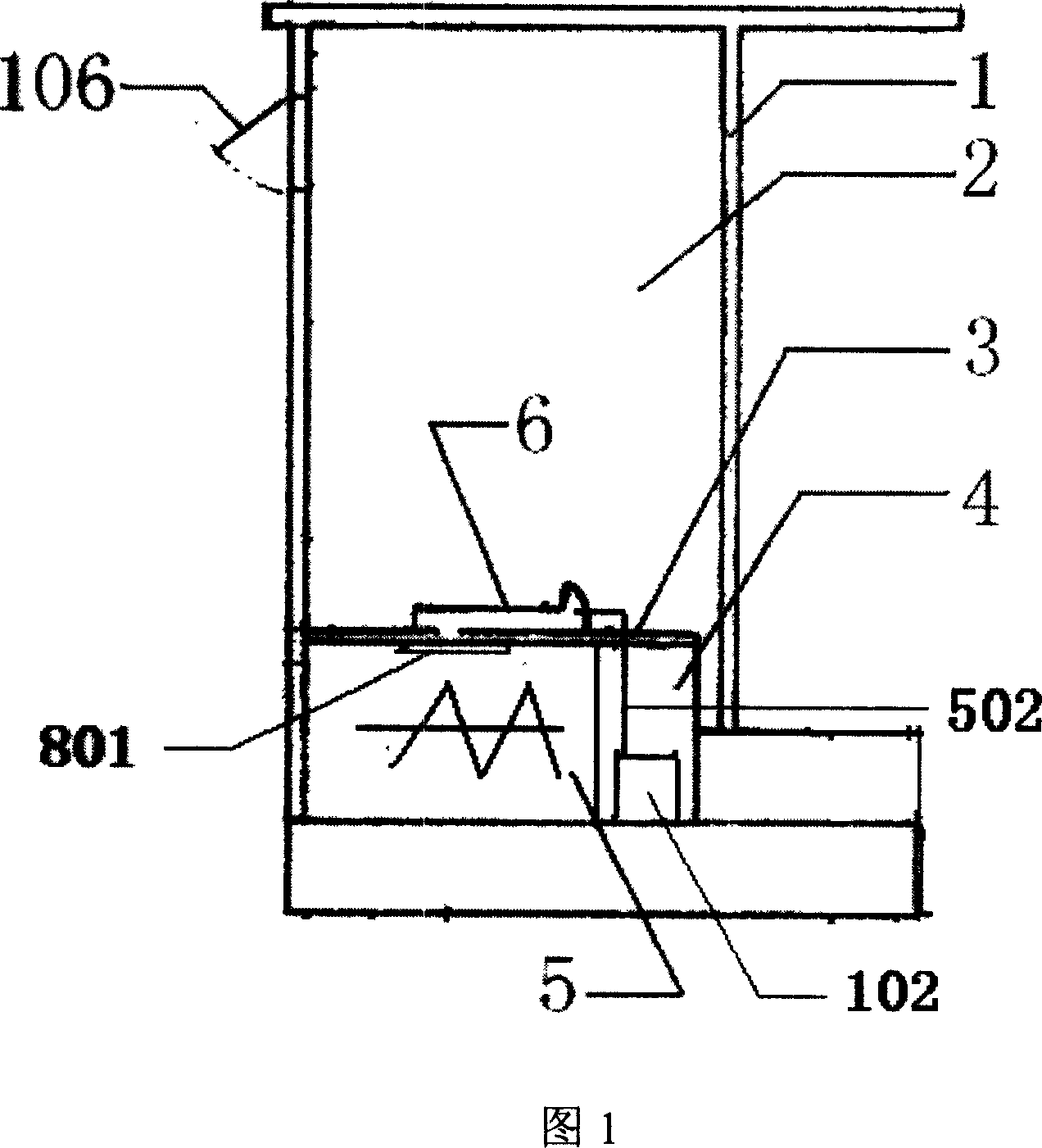

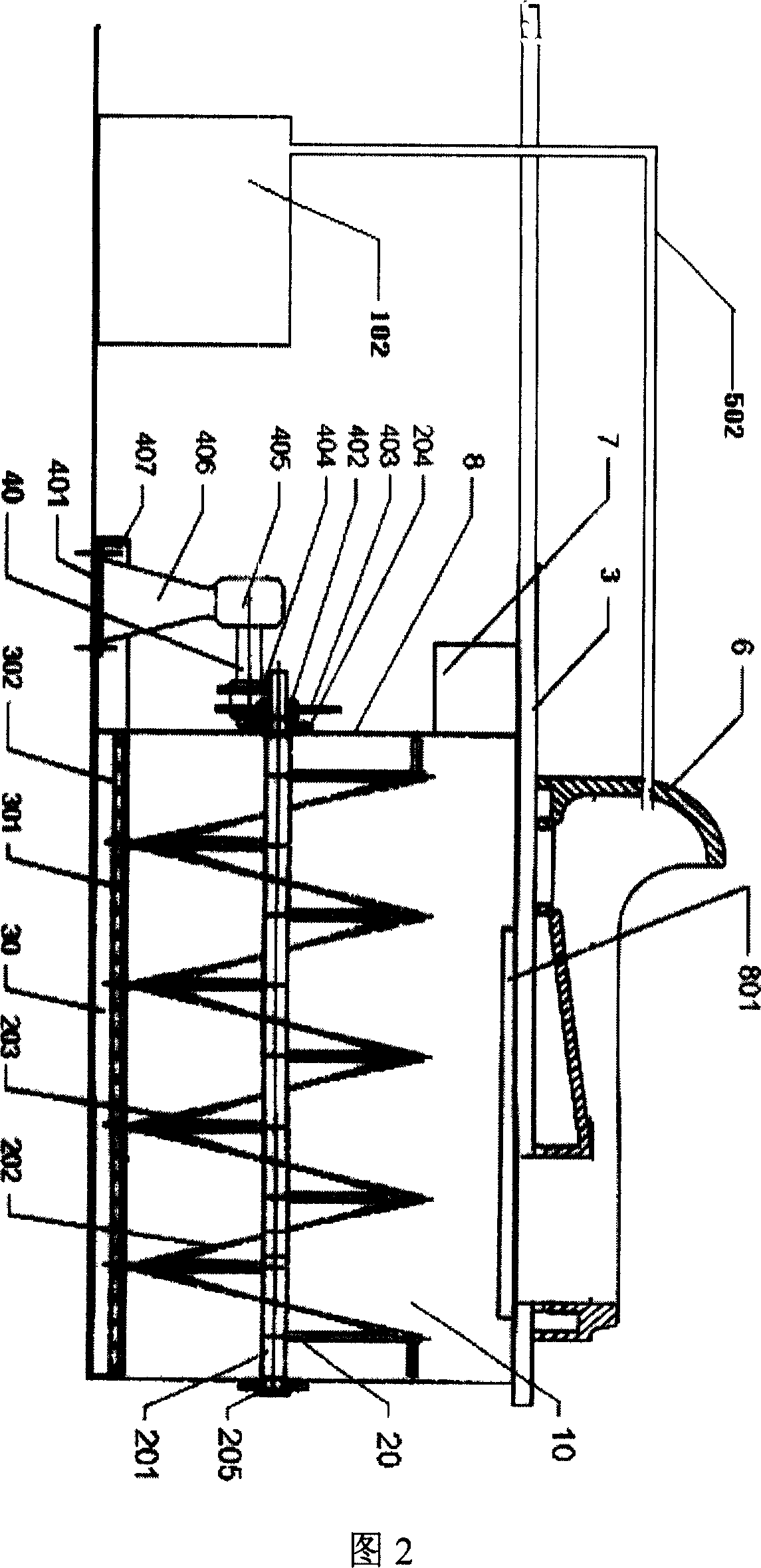

[0021] Example 2 toilet example

[0022] As shown in Figs. 1-2, the foaming ecological non-flushing toilet 1 includes a squatting room 2 arranged on a base surface 3 and a processing room 4 arranged below the base surface 3. Preferably, the toilet 1 has a toilet door on the front. Among them, a squatting pan 6 is installed in the squatting pan 2 and the squatting pan 6 is installed on the base surface 3; the processing chamber 4 is provided with a host machine 5; the host machine 5 includes a fermentation tank 8 and a mechanical transmission installed outside the fermentation tank 8. The device 40, the mechanical transmission device 40 is connected to the agitator 20 in the fermentation tank 8. The fermentation tank is equipped with the microbial agent 10, the outer bottom of the fermentation tank 8 is provided with a heating device 30; the upper part of the fermentation tank 8 is provided with the squatting pan The movable baffle 801 corresponding to the bottom opening of 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com