Disappeared mould and water-based paint composite powder additive used for sand casting

A technology of sand casting and water-based coatings, which is applied to casting molding equipment, coatings, casting molds, etc. It can solve the problems of human body and environmental hazards, cumbersome preparation process, and high price, and achieve transportation cost savings, good benefits, and low prices. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The raw materials in the formula of the present invention, except the ripened fern potato powder, all other raw materials belong to commercialized purchased powder materials.

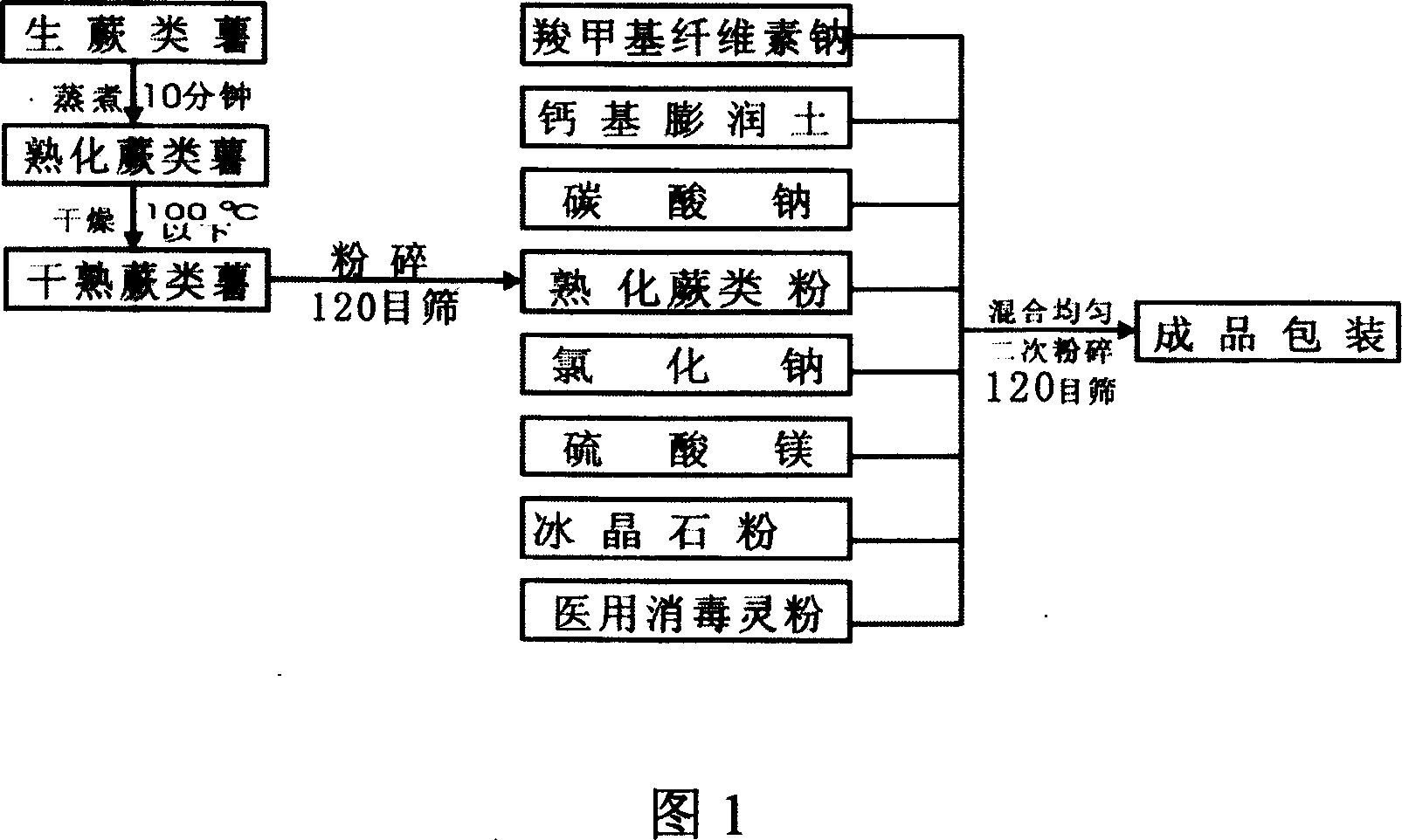

[0023] To produce 1000kg of the lost foam and sand casting water-based coating additives, weigh 250kg of fern potato powder made from fern root plant tubers or potato pieces, which are cooked, dried and crushed through a 120-mesh sieve below 100°C, Carboxymethylcellulose sodium 120kg, calcium-based bentonite 320kg, sodium carbonate 60kg, magnesium sulfate 80kg, sodium chloride 60kg, medical disinfectant powder 60kg, cryolite powder 50kg, mix evenly, crush through a 120-mesh sieve, and pack in separate bags. .

[0024] When using, mix 100 parts by weight of refractory base powder with 10 parts by weight of this powder, add 120 parts by weight of water, stir for 10 minutes, and then it can be used. You can also adjust the required concentration by adding water, and then stir for 5 minutes. Use or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com