Ordered organic-inorganic hybrid mesoporous silica and loaded gold nanomaterials, and preparing method thereof

A technology of mesoporous silica and nano-gold, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the organic function The group distribution is not uniform, the size distribution of gold particles is difficult to control, etc., which is beneficial to environmental protection, good catalytic application prospects, and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

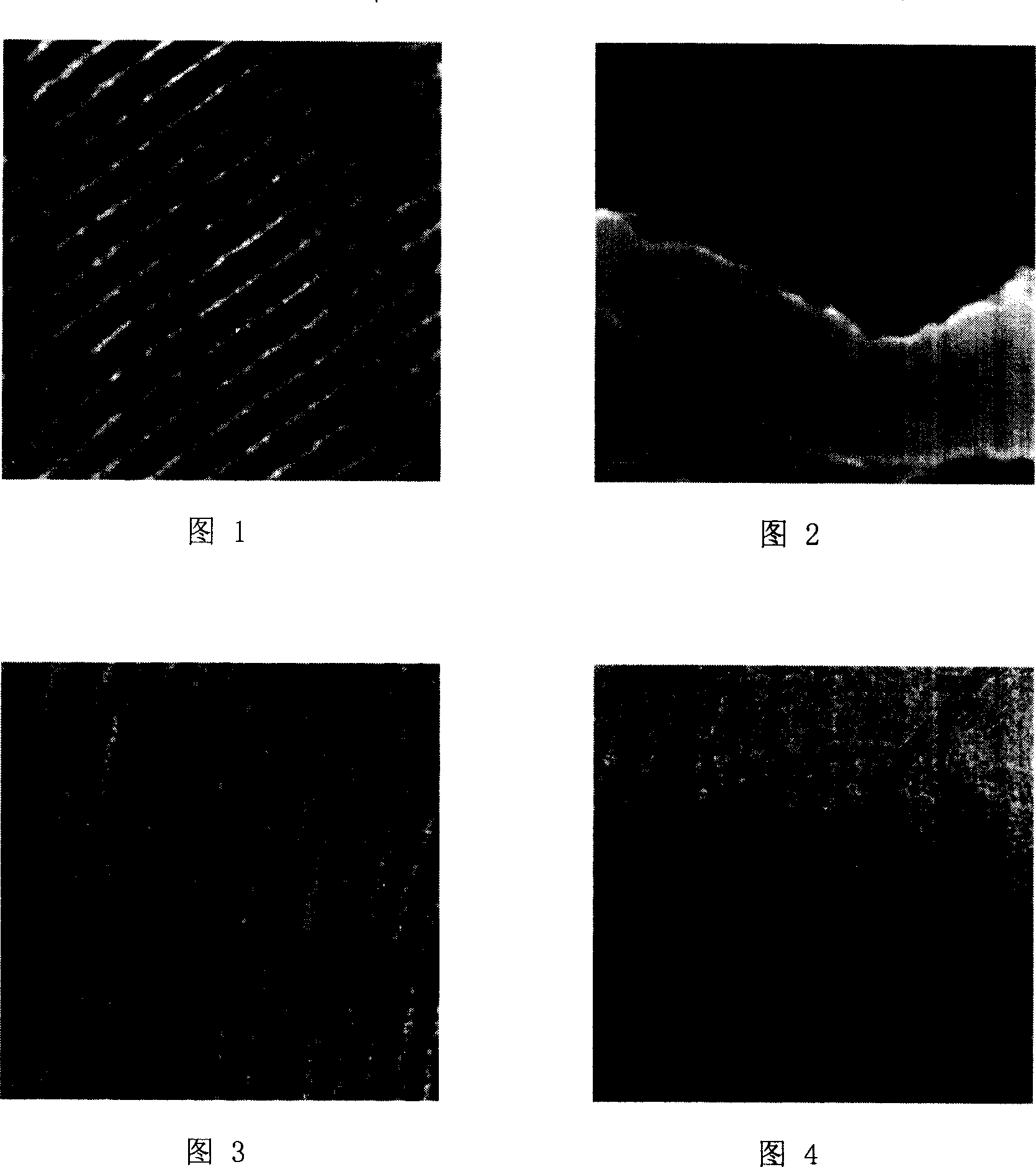

Image

Examples

Embodiment 1

[0038] 1. Dissolve 5ml of 6-mercapto-1-hexanol in 20ml of absolute ethanol with stirring at room temperature, then add 13.8g of iodine, and stir for 24 hours. After the solvent was removed by rotary evaporation, 30 ml of tert-butyl methyl ether was added, and then the iodine was extracted with 10 mg / ml sodium bisulfite solution, and the solvent was removed by rotary evaporation. Add 5 ml of thionyl chloride to the residue, stir at room temperature for 24 hours, and remove volatile substances by rotary evaporation. Finally, 5ml of 3-ethoxysilylpropyl-4,5-dihydroimidazolium ionic liquid was added to the residue, heated to reflux for 24 hours under the protection of N2, and the volatile matter was removed in vacuum to obtain a viscous liquid, which contained thioether The imidazole-based ionic liquid organofunctional siloxane precursor.

[0039] 2. Keep the temperature at 35°C, dissolve 4.0g P123 in 150ml 1.6M (M is mol / l) hydrochloric acid solution to make the pH of the solutio...

Embodiment 2

[0042] 1. Dissolve 5ml of 9-mercapto-1-nonanol in 20ml of absolute ethanol with stirring at room temperature, then add 13.8g of iodine, and stir for 24 hours. After the solvent was removed by rotary evaporation, 30 ml of tert-butyl methyl ether was added, and then iodine was extracted with 15 mg / ml sodium bisulfite solution, and the solvent was removed by rotary evaporation. Add 5 ml of thionyl chloride to the residue, stir at room temperature for 24 hours, and remove volatile substances by rotary evaporation. Finally, 5ml of 3-ethoxysilylpropyl-4,5-dihydroimidazolium ionic liquid was added to the residue, heated to reflux for 24 hours under the protection of N2, and the volatile matter was removed in vacuum to obtain a viscous liquid, which contained thioether The imidazole-based ionic liquid organofunctional siloxane precursor.

[0043] 2. With the temperature kept at 35°C, dissolve 4.0g of P123 in 150ml of 1.6M hydrochloric acid solution to make the pH of the solution reac...

Embodiment 3

[0046] 1. Dissolve 5ml of 3-mercapto-1-propanol in 20ml of absolute ethanol with stirring at room temperature, then add 13.8g of iodine, and stir for 24 hours. After the solvent was removed by rotary evaporation, 30 ml of tert-butyl methyl ether was added, and then iodine was extracted with 15 mg / ml sodium bisulfite solution, and the solvent was removed by rotary evaporation. Add 5 ml of thionyl chloride to the residue, stir at room temperature for 24 hours, and remove volatile substances by rotary evaporation. Finally, 5 ml of 3-ethoxysilylpropyl-4,5-dihydroimidazolium ionic liquid was added to the residue under N 2 Heating to reflux under protection for 24 hours, removing volatile matter in a vacuum to obtain a viscous liquid, that is, an imidazole-based ionic liquid organofunctional siloxane precursor containing thioether.

[0047] 2. With the temperature kept at 35°C, dissolve 4.0g of P123 in 150ml of 1.6M hydrochloric acid solution to make the pH of the solution reach 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com