Modified polybutadiene anticorrosion paint for steel plate

A technology of polybutadiene and anti-corrosion coatings, which is applied in coatings, devices for coating liquids on surfaces, etc. It can solve the problems of basic resin performance limitations, difficulty in upgrading and replacement, etc., and achieve low cost and high and low temperature resistance Excellent, excellent high and low temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

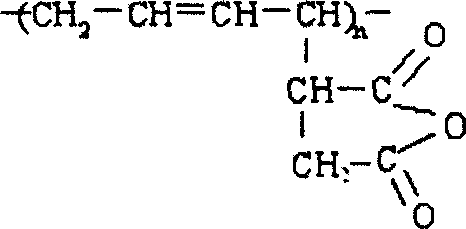

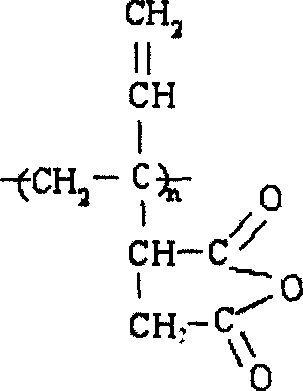

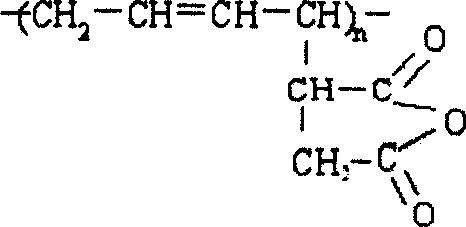

Method used

Image

Examples

Embodiment 1

[0047] In a four-necked glass reaction flask with a volume of 3 liters, add 1,000 g of 1,2-low molecular weight polybutadiene, with a number average molecular weight of 1030, a 1,2-structure of 72%, and a viscosity of 1,200 cp at 20°C. Add 300g of xylene, 165g of maleic anhydride, 2g of N-phenyl-N-isopropyl-p-phenylenediamine, pass through dry nitrogen, start stirring, and slowly heat up the reactant to 180°C, react for 9 hours, at 1, 2-Reaction between low molecular weight polybutadiene and maleic anhydride. After the reaction, the temperature is lowered to 150°C. Distillation under reduced pressure removes xylene and unreacted maleic anhydride. The resulting product has a viscosity of 38,000 cp (30°C). The acid value was 82.5 mgKOH / g.

[0048] Take 300 g of the above-mentioned reactant, place it in a four-necked glass reaction flask with a volume of 1 liter, add 1 g of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexyne-3, 0.3 g of 1,4-bis(2-benzoxazolyl)naphthalene, add 301g xyle...

Embodiment 2

[0056] In a four-necked glass reaction flask with a volume of 1 liter, add the maleic anhydride polybutadiene prepared in 100 g of Example 1, 200 g of 1,2-low molecular weight polybutadiene with a number average molecular weight of 1030, add 2 g tert-butyl peroxybenzoate, 0.1g of 4,4'-bis(2-disulfonate sodium styryl)biphenyl, 302g of xylene, under the protection of nitrogen, slowly raise the temperature to 80°C, and stir for 10 hours , to make a solid content of 50%, a varnish with a viscosity of 160cp (20°C).

[0057] Take 300g of the above-mentioned varnish, add 75g of titanium dioxide, mix 125g of xylene, grind in a small sand mill to a particle size of ≤30 μm, and make a color paint with a solid content of 45% and a viscosity of 70cp (20°C).

[0058] Dip the cleaned 0.2mm thick tinplate sheet into varnish and color paint respectively, take it out, put it in an oven at 200°C and bake for 10 minutes, make samples of varnish and color paint, and test it. The test results are ...

Embodiment 3

[0064] In a glass reaction bottle with a volume of 1 liter, add 300 g of 1,2-low-molecular polybutadiene with a number average molecular weight of 1200, 3 g of benzoyl peroxide, and 303 g of cyclohexane, and slowly heat up to 80 °C under nitrogen protection. ℃, and reacted for 6 hours to prepare a varnish with a solid content of 50% and a viscosity of 85 cp (20 ℃).

[0065] Take 300g of the above-mentioned varnish, add 75g of titanium dioxide and 125g of cyclohexane, grind it in a small sand mill to a particle size of ≤30 μm, and make a color paint with a solid content of 45% and a viscosity of 55cp (20°C).

[0066] Dip the cleaned 0.2mm thick tinplate sheet into varnish and color paint respectively, take it out, and bake it in an oven at 220°C for 5 minutes to make samples of varnish and color paint for testing. The test results are as follows:

[0067] Sample Thickness / μm Hardness Adhesion Impact Strength / kg / cm Salt Spray Resistance / hour

[0068] Varnish 21 2H Level 2 ≥50 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com