Denitrification facultative type domestic refuse bioreactor landfill and leachate recirculation process

A bioreactor and domestic waste technology, applied in gas production bioreactors, aerobic and anaerobic process treatment, waste fuel, etc., to achieve the effects of reduced treatment costs, simple construction and construction of facilities, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: This example is a preferred example.

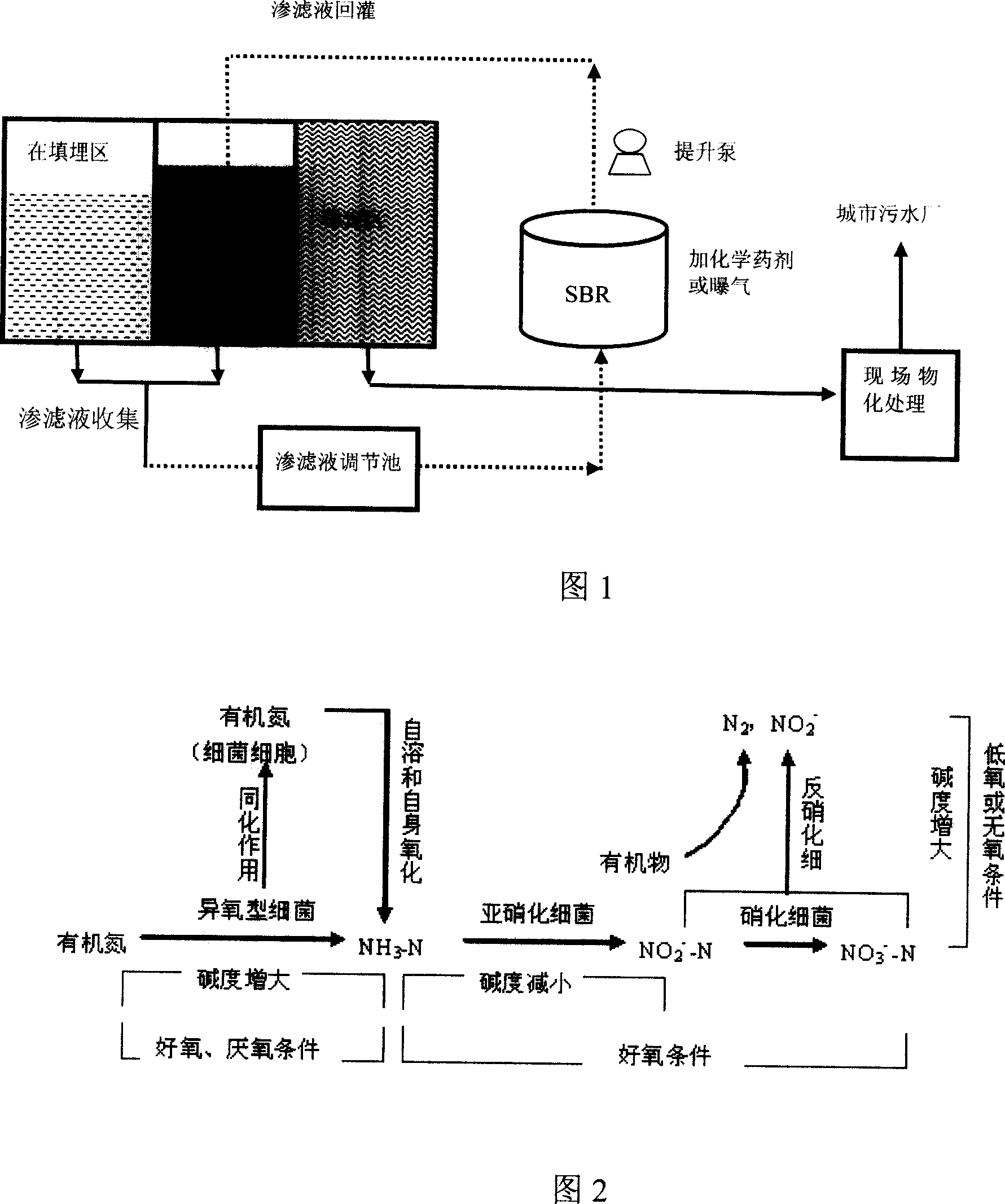

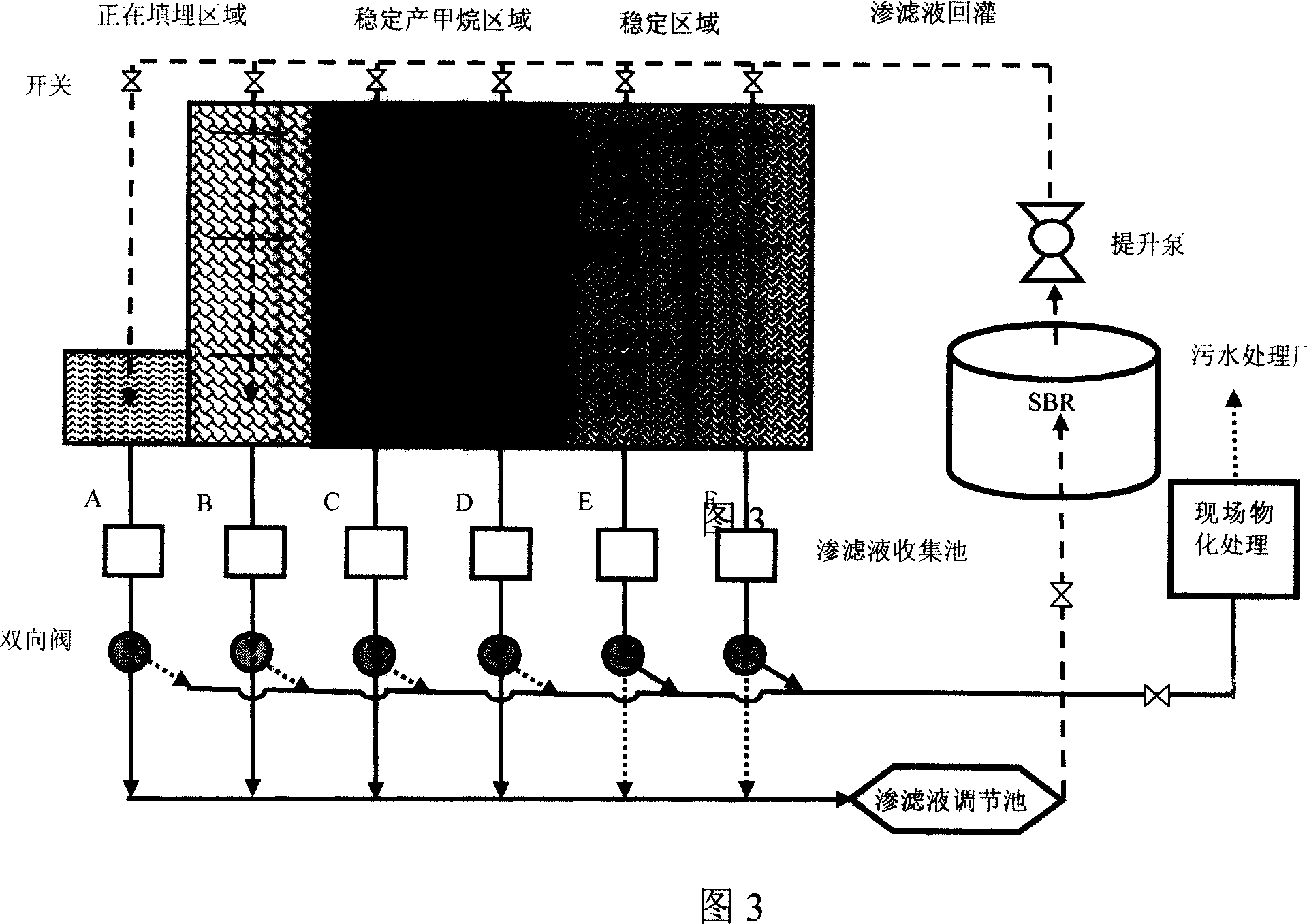

[0032]As shown in Figures 1 and 2, the waste stabilization time of the bioreactor landfill is 6 years, so 6 landfill units are set up, and the capacity of each landfill unit is designed according to the waste treatment capacity of one year. A leachate collection pipe is set at the bottom of the buried layer. The collection pipe can flow into the leachate adjustment tank through the two-way valve control through the leachate collection tank for refilling pretreatment or into the physical and chemical treatment facility for further treatment and discharge according to the standard. Next, you can also set the controller to realize automatic control of this function, reduce personnel input and improve later operation efficiency. At the same time, a 2m high garbage dam was built between each landfill unit to prevent leachate from flowing into other landfill units when the water level in the landfill is high. Starting from the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com