Reflection decreasing material, and electronic image displaying device using it

An anti-reflection layer and reflection curve technology, applied in the field of anti-reflection laminated films, can solve the problems of detrimental to the color reproducibility of the display device and the color rendering of the anti-reflection layer, reducing the quality of the display device, and detrimental to the appearance of the display device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

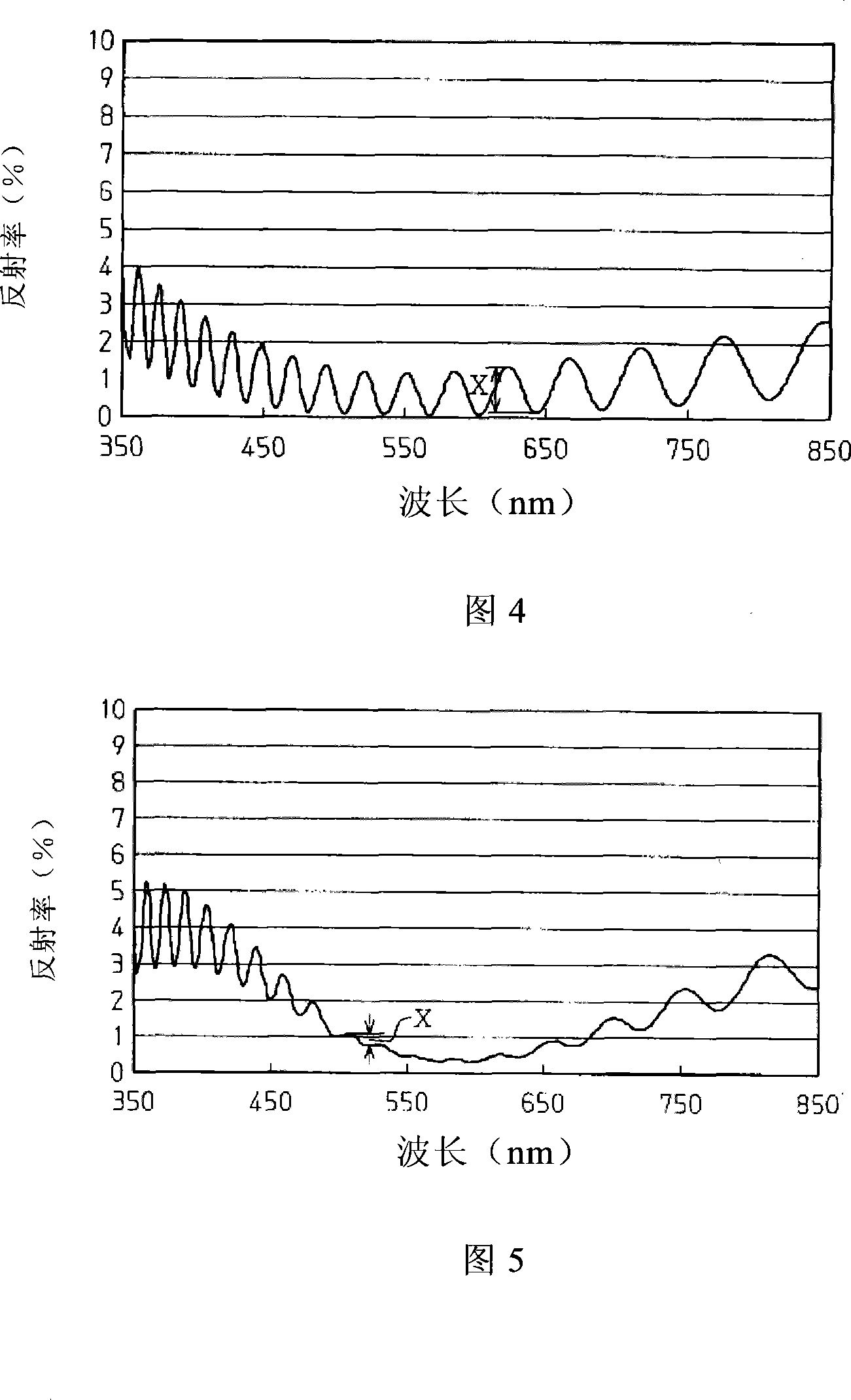

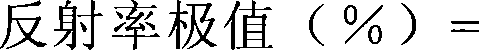

[0072] Preparation examples, examples, and comparative examples of the present invention will now be described. First, the measurement of the refractive index of the cured coating liquid forming the antireflection layer will be described.

[0073] (1) Using a dip coater (manufactured by Sugiyama Moto Rikaki Co., Ltd.), the coating liquid for forming the antireflection layer was applied to an acrylic plate with a refractive index of 1.49 (trade name: "Delaglas A", Asahi Kasei Industries, Ltd. Co., Ltd.) on. The amount of the coating liquid used was adjusted so that a layer having an optical film thickness of about 550 nm could be formed after drying.

[0074] (2) The solvent is removed from the coating liquid layer to form a dried coating film. If necessary, the coating liquid was cured by irradiating with 400 mJ of ultraviolet rays from a 120 W high-pressure mercury lamp in a nitrogen atmosphere using an ultraviolet radiation apparatus (manufactured by Iwasaki Electric Co., ...

manufacture example 1-1

[0094] [Manufacturing Example 1-1: Preparation of Coating Liquid for Interference Layer Formation (IF-1)]

[0095] By dissolving or dispersing 30 parts by mass of dipentaerythritol hexaacrylate, 20 parts by mass of tetramethylolmethane triacrylate, and 50 parts by mass of tin oxide with an average particle diameter of 0.05 μm in 1000 parts by mass of 2-butanol Microparticles and 2 parts by mass of a photopolymerization initiator (trade name: IRGACURE907, manufactured by Ciba Specialty Chemicals) were used to prepare a coating solution (IF-1) for forming an interference layer. The refractive index of the cured product of the coating liquid (IF-1) was 1.58.

manufacture example 1-2

[0096] [Manufacturing Example 1-2: Preparation of coating solution (HC-1) for forming a hard coat layer]

[0097] By adding 70 parts by mass of dipentaerythritol hexaacrylate, 30 parts by mass of 1,6-bis(3-acryloyloxy-2-hydroxypropoxy) hexane, 4 parts by mass of photopolymerization initiator (trade name : IRGACURE 184, manufactured by Chiba Specialty Chemical), and 100 parts by mass of isopropyl alcohol were mixed to prepare a coating liquid (HC-1) for forming a hard coat layer. The refractive index of the cured product of the coating liquid (HC-1) was 1.52.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com