Transition metal catalyst for oligomerization and polymerization of ethylene and its prepn process and use

A catalyst and complex technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as limiting the development of ethylene oligomerization and polymerization industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

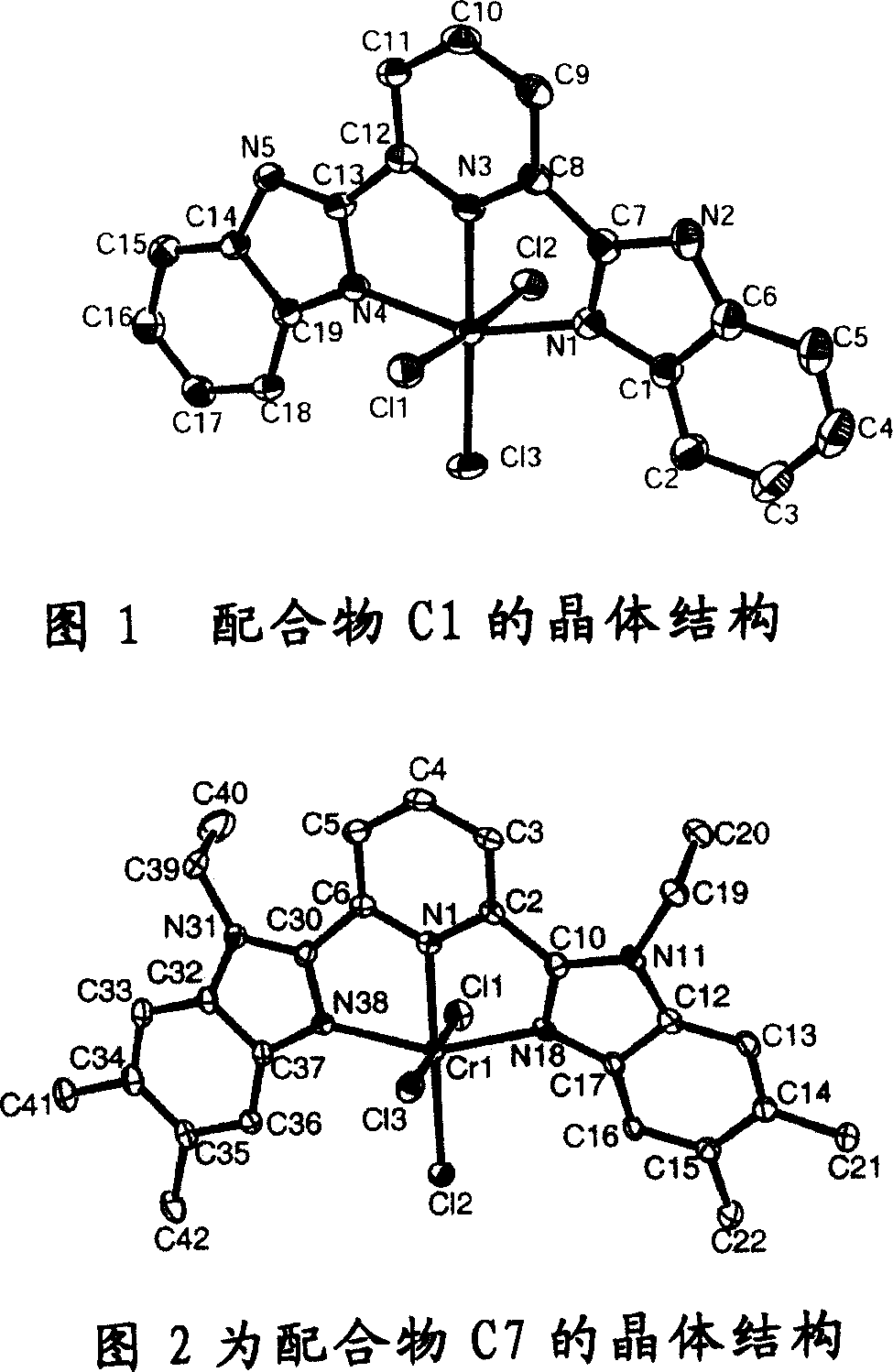

[0068] 1. The preparation of catalyst C1: Chromium chloride tetrahydrofuran (0.1315g, 0.35mmol) and corresponding benzimidazolpyridine L1 (0.1093g, 0.35mmol) are added in the Schlenk bottle, and the logical N 2 After three replacements, add treated dichloromethane (10ml), stir at room temperature for 24 hours, add anhydrous diethyl ether after concentration, and a green precipitate precipitates out. After filtering, vacuum-dry to obtain the complex 0.118g, C1 yield: 75.0 %. Elemental Analysis Theoretical Value C 19 h 12 C l3 CrN 5 : C, 48.59; H, 2.79; N, 14.91; Found: C, 48.30; H, 2.80; N, 14.54%. IR(KBr:cm -1 ): 3070 (v N-H ), 1609 (v C=C ), 1468(δ N-H ), 1321, 1147, 998, 826, 754 (δ N-H ).

[0069] 2. Ethylene oligomerization: Dry the 250ml polymerization bottle equipped with a magnetic stirrer at 130°C for 6 hours continuously, vacuumize while it is hot and use N 2 Air replacement 3 times. Catalyst C1 (2.3 mg, 5 μmol) was added, followed by evacuation and replac...

Embodiment 2

[0071] 1. The preparation of catalyst C1 is the same as in Example 1.

[0072] 2. Ethylene oligomerization: Vacuumize a 250 ml stainless steel kettle equipped with a mechanical stirrer and a thermocouple, replace it with nitrogen for 3 times, and then replace it with ethylene for 2 times. After cooling to 40°C, sequentially add the toluene solution of catalyst C1 (0.9mg, 2μmol) and a certain amount of toluene, and finally add a certain amount of methylaluminoxane (1.46mol / L, 3.4ml) to make Al / Cr=1000 , the total volume of toluene is 100ml. The ethylene pressure was immediately raised to 10 atm and stirred vigorously at 40°C for 60 minutes. After cooling, take out a little reaction solution, neutralize the MAO in it with dilute hydrochloric acid at 0°C, take a small amount of toluene layer, dry it with anhydrous sodium sulfate, and measure the content and distribution of oligomers by gas chromatography. Oligomerization activity: 14.0×10 6 g(oligomer)·mol -1 (Cr) h -1 . Ol...

Embodiment 3

[0074] 1. The preparation of catalyst C1 is the same as in Example 1.

[0075] 2. Ethylene polymerization: Dry the 250ml polymerization bottle equipped with a magnetic stirrer at 130°C for 6 hours continuously, vacuumize it while it is hot and use N 2 Air replacement 3 times. Catalyst C1 (2.3 mg, 5 μmol) was added, followed by evacuation and replacement with ethylene twice. A certain amount of toluene (29.6ml) was injected with a syringe, and a hexane solution of diethylaluminum chloride (0.375ml) was added. Make Al / Cr = 150, keep the ethylene pressure of 1 atm at 25°C, and stir vigorously for 60 minutes. Add 5% hydrochloric acid ethanol solution to the reaction solution for neutralization, and a white solid precipitates out. After filtration it was vacuum dried for 12 hours. Obtained product 0.075g, polymerization activity: 1.5×10 4 g·mol -1 (Cr) h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com