Integrated bubble-free aeration biological composite film film-separation biological reactor

A bioreactor, bubble-free aeration technology, applied in sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve problems such as inability to guarantee biofilm, poor operational stability, and inability to guarantee treatment effects. , to achieve the effect of convenient and accurate control of aeration volume, improvement of oxygen transfer efficiency, and reduction of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

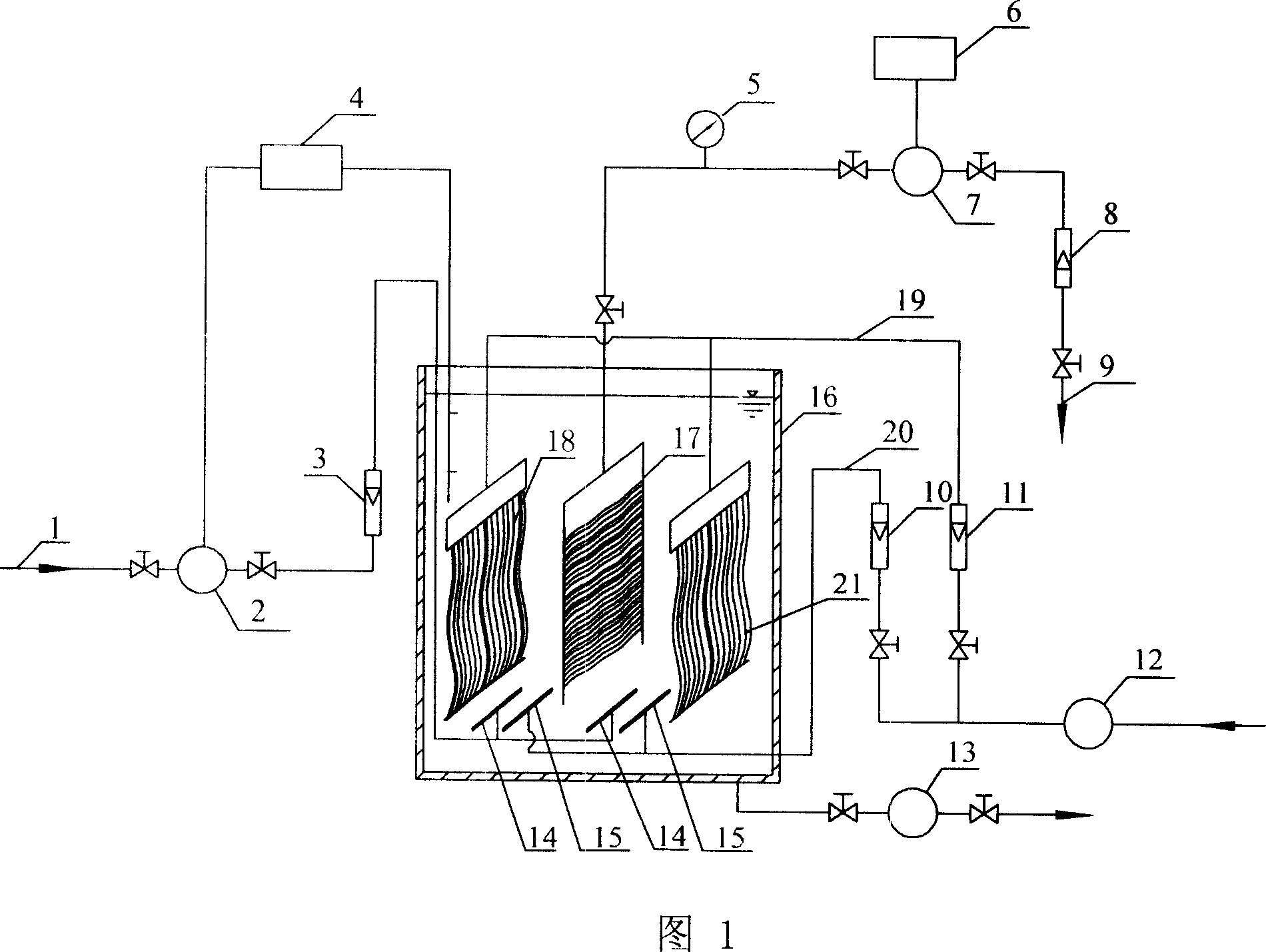

[0007] Specific embodiment one: (referring to Fig. 1) present embodiment consists of water inlet pipe 1, water inlet pump 2, suction pump 7, water outlet pipe 9, air blower 12, mud discharge pump 13, perforated water distribution pipe 14, perforated aeration pipe 15, The biochemical reactor 16, the solid-liquid separation membrane module 17, the first bubble-free aerated biofilm module 18, the air inlet pipe 19 and the aeration connecting pipe 20 are composed of the solid-liquid separation membrane module 17 and the first bubble-free aerated biofilm The components 18 are vertically arranged in the biochemical reactor 16 respectively, the solid-liquid separation membrane component 17 and the first bubble-free aerated biofilm component 18 are parallel to each other, the solid-liquid separation membrane component 17 is connected with the outlet pipe 9, and the suction pump 7 Connected in series on the water outlet pipe 9, the perforated water distribution pipe 14 and the perforate...

specific Embodiment approach 2

[0008] Specific embodiment two: (see Fig. 1) The difference between this embodiment and specific embodiment one is that a second non-bubble aerated biofilm assembly 21 is added in the biochemical reactor 16, and the second non-bubble aerated biological The membrane module 21 is arranged in the biochemical reactor 16 and arranged symmetrically with the first bubble-free aerated biofilm module 18 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific embodiment three: (see Fig. 1) the upper ends of the solid-liquid separation membrane module 17, the first bubble-free aerated biofilm module 18 and the second bubble-free aerated biofilm module 21 of this embodiment are respectively lower than the biochemical reactor 16 The inner water surface is 30-40 cm. Other compositions and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com