Polyamide copolymer/clay nano composite material, its preparing and use

A nanocomposite material and composite material technology, applied in the field of exfoliated polyamide copolymer/clay nanocomposite material and its preparation, can solve the problems of increased film haze, poor film appearance and transparency, and decreased impact toughness of composite materials, etc. Achieve the effect of improving breaking strength and modulus, improving transparency and flexibility, and improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

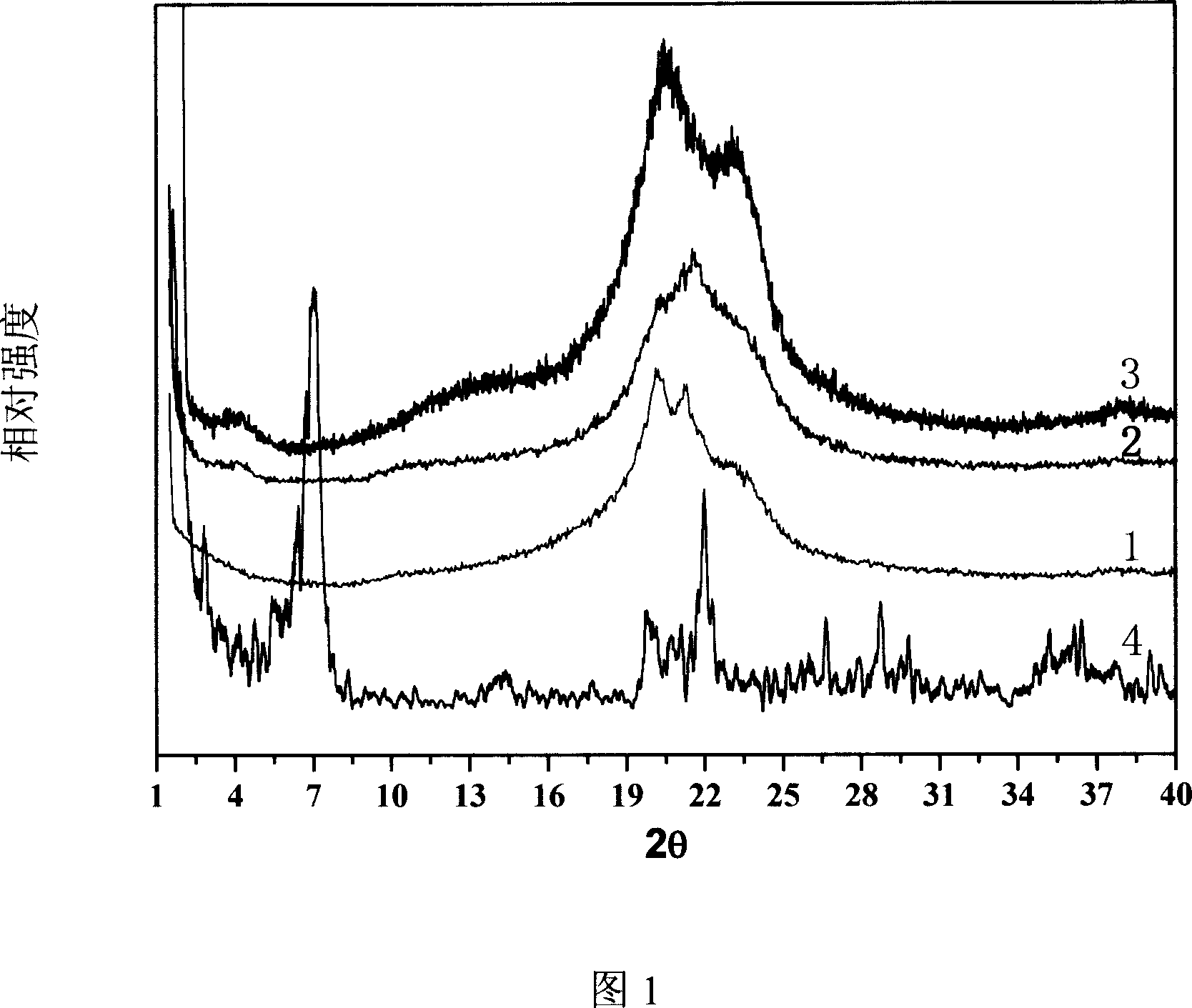

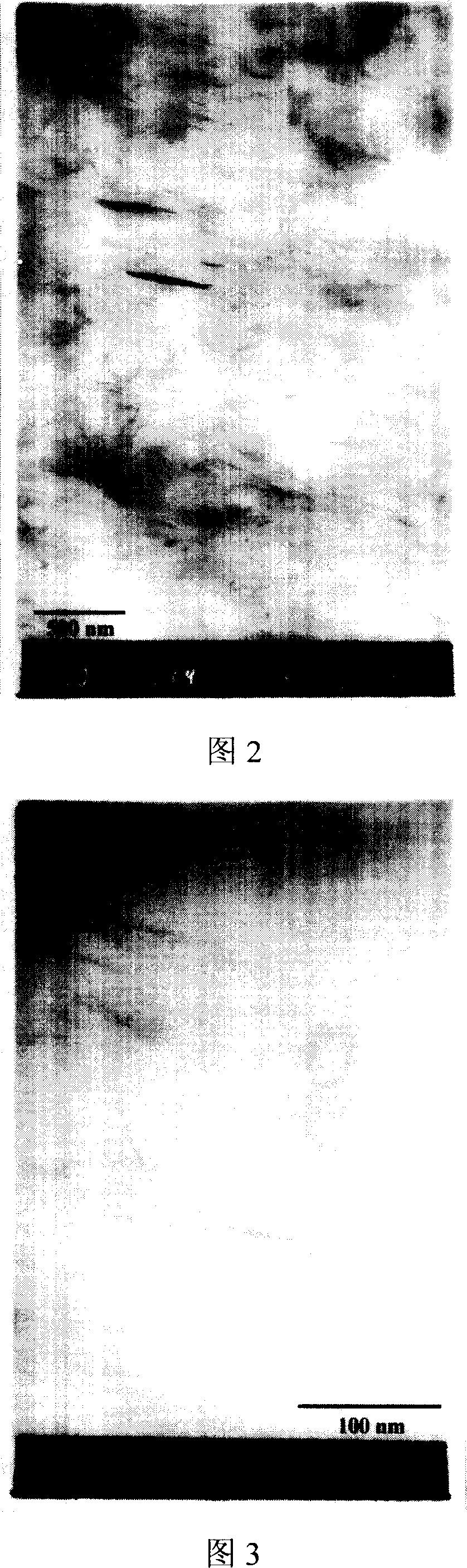

Embodiment 1

[0051] (1) Add 2.5 kg of montmorillonite and 0.2 kg of trimethyl phosphate into 25 kg of deionized water with a total capacity of cation exchange of 100meq / 100g, a particle size of 200 mesh, and stir at a high speed for 0.5 hour to obtain the aqueous suspension A of montmorillonite . (2) 0.5 kg of aminocaproic acid, 1.1 kg of octadecyltrimethylammonium bromide, and 0.5 kg of phosphoric acid were dissolved in 50 kg of deionized water to obtain organic solution B. (3) Add B dropwise to A under stirring, keep the temperature at 80° C., stir and react for 6 hours, cool to room temperature naturally, separate and wash by pressure filtration to obtain about 6.25 kg of a filter cake with a water content of 60%. (4) Then, the filter cake, 100kg of caprolactam, 3kg of nylon 66 salt and 40g of adipic acid were stirred and mixed in a melting tank at 90-100°C for 6 hours, and then fed into a storage tank for polymerization. (5) Continuously feed into the pre-polymerization tube, and cond...

Embodiment 2

[0054] (1) Add 5 kg of Ili stone with a total cation exchange capacity of 60 meq / 100 g, a particle size of 200 mesh, and 0.4 kg of trimethyl phosphate into 25 kg of ethanol, and stir at high speed for 0.5 hour to obtain alcohol suspension A of Ili stone. (2) 2kg of caprolactam, 3kg of dioctadecyldimethylammonium chloride, and 0.7kg of hydrochloric acid were dissolved in 50kg of deionized water to obtain organic solution B. (3) Add B dropwise to A under stirring, keep the temperature at 90° C., stir and react for 6 hours, cool to room temperature naturally, separate and wash by pressure filtration to obtain about 10 kg of a filter cake containing 100% water. (4) Then, the filter cake, 100kg of caprolactam, 5kg of nylon 66, and 20g of adipic acid were stirred and mixed in a melting tank at 90-100°C for 6 hours, and then fed into a storage tank for polymerization. (5) Continuously feed into the pre-polymerization tube, and conduct ring-opening polymerization reaction at 270° C. a...

Embodiment 3

[0057] (1) Add 1.5 kg of montmorillonite, 1.5 kg of kaolinite, and 0.24 kg of triethyl phosphate into 25 kg of deionized water with a total capacity of cation exchange of 100meq / 100g and 20meq / 100g, and high-speed stirring for 0.5 hours, an aqueous suspension A of the clay was obtained. (2) 0.3kg of undecyl amino acid, 2.4kg of tri(dodecyl)methyl ammonium bromide, and 0.5kg of sulfuric acid were dissolved in 50kg of deionized water to obtain organic solution B. (3) Add B dropwise to A under stirring, keep the temperature at 100° C., stir and react for 6 hours, cool to room temperature naturally, separate and wash by pressure filtration to obtain about 6 kg of a filter cake containing 50% water. (4) Then, stir and mix the filter cake, 100kg caprolactam, 2kg nylon 66, 1kg laurolactam and 30g acetic acid in a melting tank at 90-100°C for 6 hours, and then discharge them into a storage tank for polymerization. (5) Continuously feed into the pre-polymerization tube, and conduct ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com