Green Trichderma of generating ethylene and culturing method therefor

A technology of Trichoderma viride and a cultivation method, which is applied in the field of fungi to achieve the effects of improving ecological indicators and living environment quality, eliminating pollution and reducing imports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

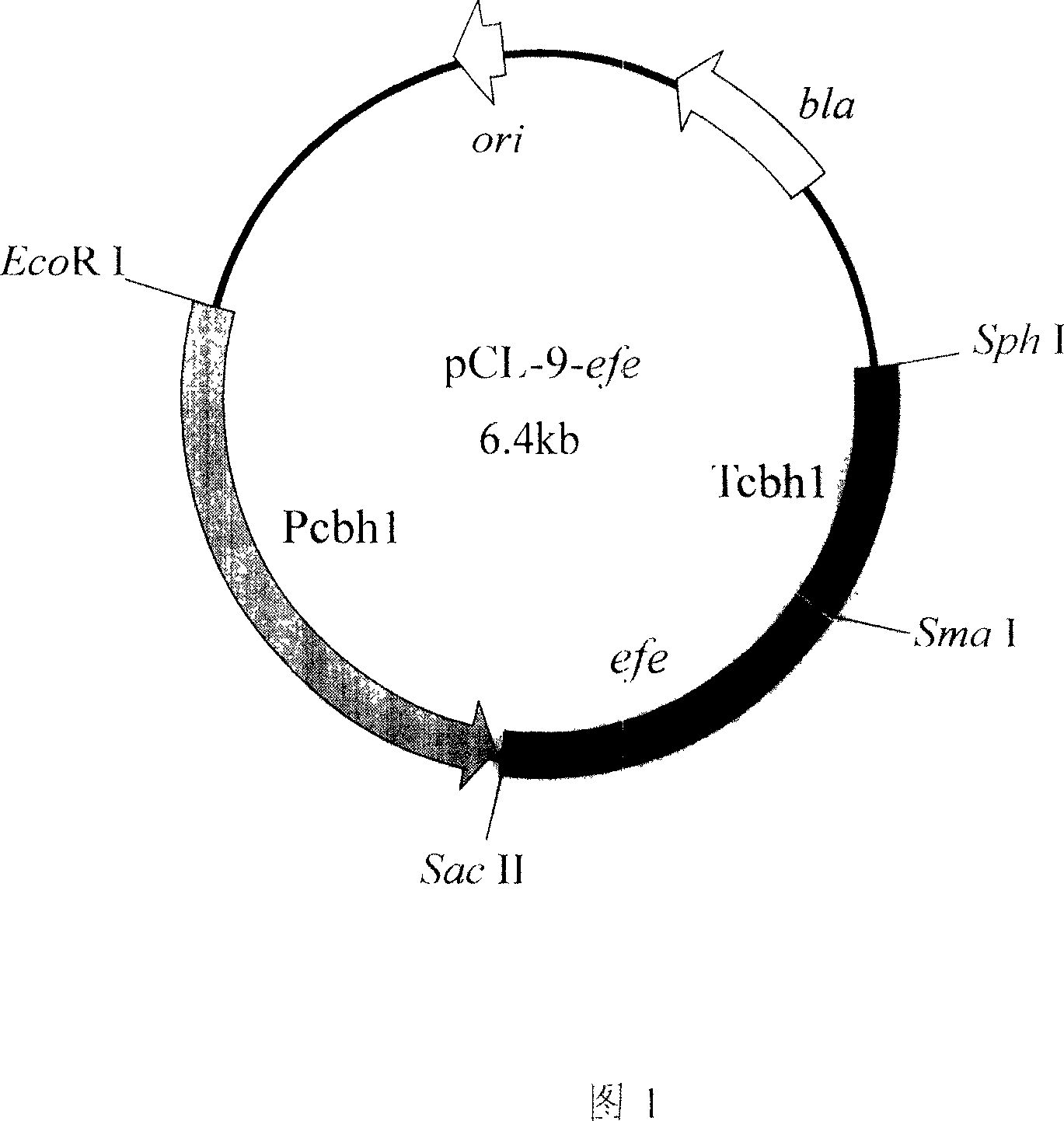

[0032] The construction of embodiment 1 Trichoderma viride (T.viride) CGMCC No.1918

[0033] The ethylene-forming enzyme gene efe (the gene sequence is reported in Fukuda H, Ogawa T, Ishihara K, et al. Molec μlar cloning in Escherichia coli, expression, and nucleotide sequence for the gene for the ethylene-forming enzyme of Pseudomonas syringae pv. phaseolicola PK2. Biochemical and Biophysical Research Communications, 1992, 188: 826-832.).

[0034] The sequence of primers used in PCR is: upstream primer P1: 5'-cc cccgcgg atgaccaacctacagactttc-3' (the underline is the Sac II site), downstream primer P2: 5'-tat cccggg aactcatgagcctgtcgcg-3' (the underline is the Sma I site).

[0035] PCR conditions were: 94°C pre-denaturation for 5 min, 94°C denaturation for 30 s, 62°C annealing for 30 s, 72°C extension for 1 min, 30 cycles, and finally 72°C extension for 10 min. The PCR machine model used is PTC200 (manufactured by MJ Company).

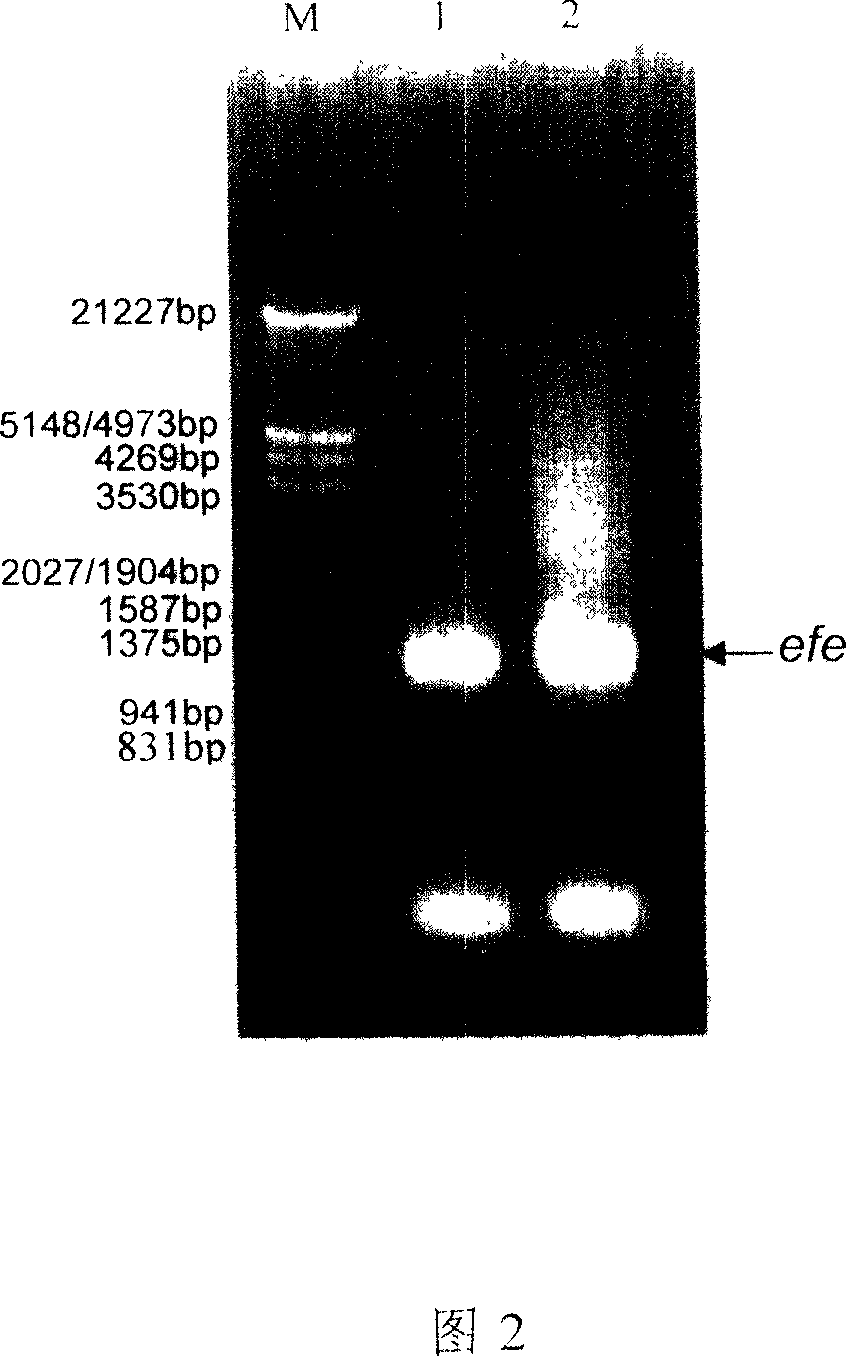

[0036] Then the PCR product was inserted in...

Embodiment 2

[0040] The cultivation of embodiment 2 Trichoderma viride (T.viride) CGMCC No.1918 and the determination of ethylene production

[0041] 1. Training:

[0042] (1) Inoculate the spores of the Trichoderma viride in the PDA medium, and cultivate for 1 week at 30°C;

[0043] (2) After the spores grow into green, scrape off the spores and suspend them in sterile water, then inoculate the spore suspension in the liquid basic medium at an inoculum volume of 1% by volume, seal the test tube with a cotton plug, and keep at 30°C, 200r / min shaking culture for 48h;

[0044] (3) Collect mycelia by centrifugation (centrifuge model TGL-16H, purchased from Zhuhai Heima Medical Instrument Co., Ltd., centrifugation parameter is 10000rpm 1min), then transfer the mycelium to liquid cellulose induction medium, test tube Seal with a rubber stopper and culture at 30°C for 36 hours with shaking.

[0045] 2. Determination of ethylene production:

[0046] Take 100 μl of gas at the top of the test t...

Embodiment 3

[0047] The measurement results are as follows: the average value of the measured peak area is 145.9, and the amount of ethylene produced by Trichoderma viride (T.viride) CGMCC No.1918 transformed cellulose powder after 36 hours of shaker fermentation is 2.075 μl / h / g dry cells. The cultivation of embodiment 3 Trichoderma viride (T.viride) CGMCC No.1918 and the determination of ethylene production

[0048] One, culture: (1) inoculate the mycelia of described Trichoderma viride in PDA medium, cultivate 1 week at 30 ℃;

[0049] (2) After the spores grow into green, scrape off the spores and suspend them in sterile water, then inoculate the spore suspension in a solid fermentation medium at an inoculum size of 10% by volume, and cultivate it statically at 30°C for 48h, then inoculate The sealing cotton plug of the test tube was replaced with a rubber stopper, and the culture was continued at 30°C for 48 hours.

[0050] Two, ethylene production is measured: assay method and instrum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com