Method for separation of components and separation unit

A separation method and separation device technology, applied in the separation method, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of unstable separation of components, poor acid resistance, etc., and achieve the effect of inhibiting capillary condensation and long-term stable component separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

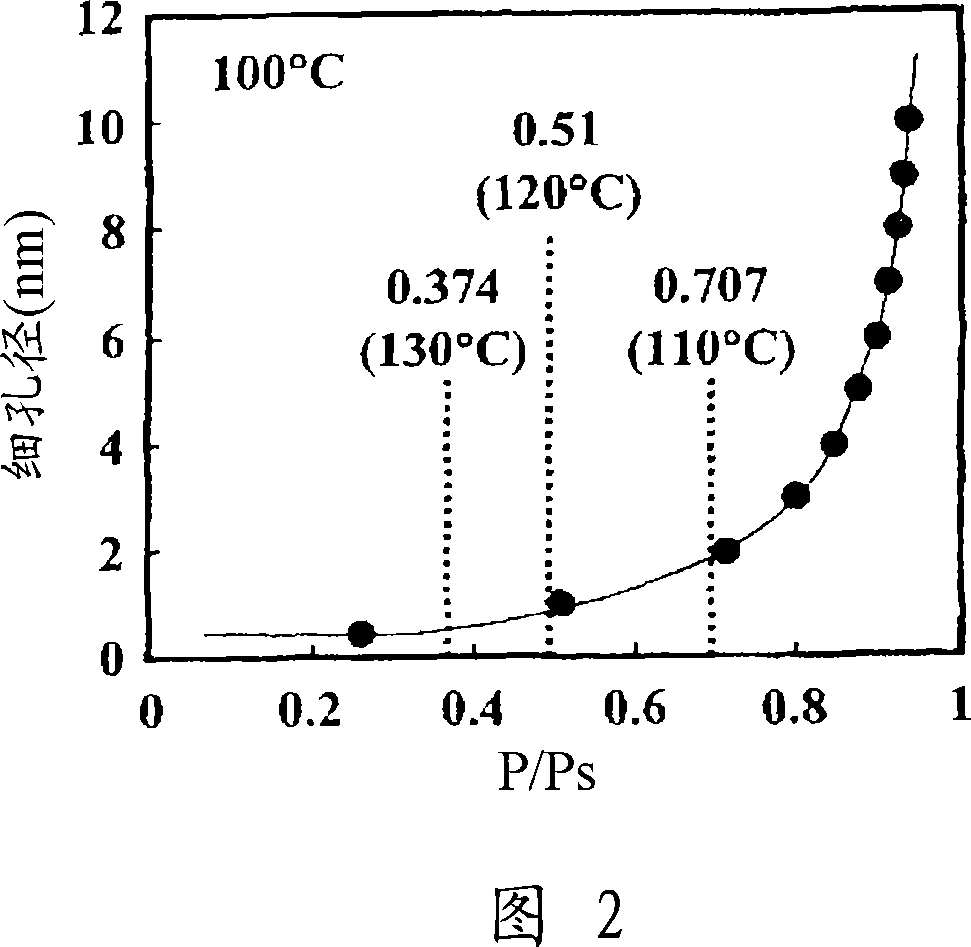

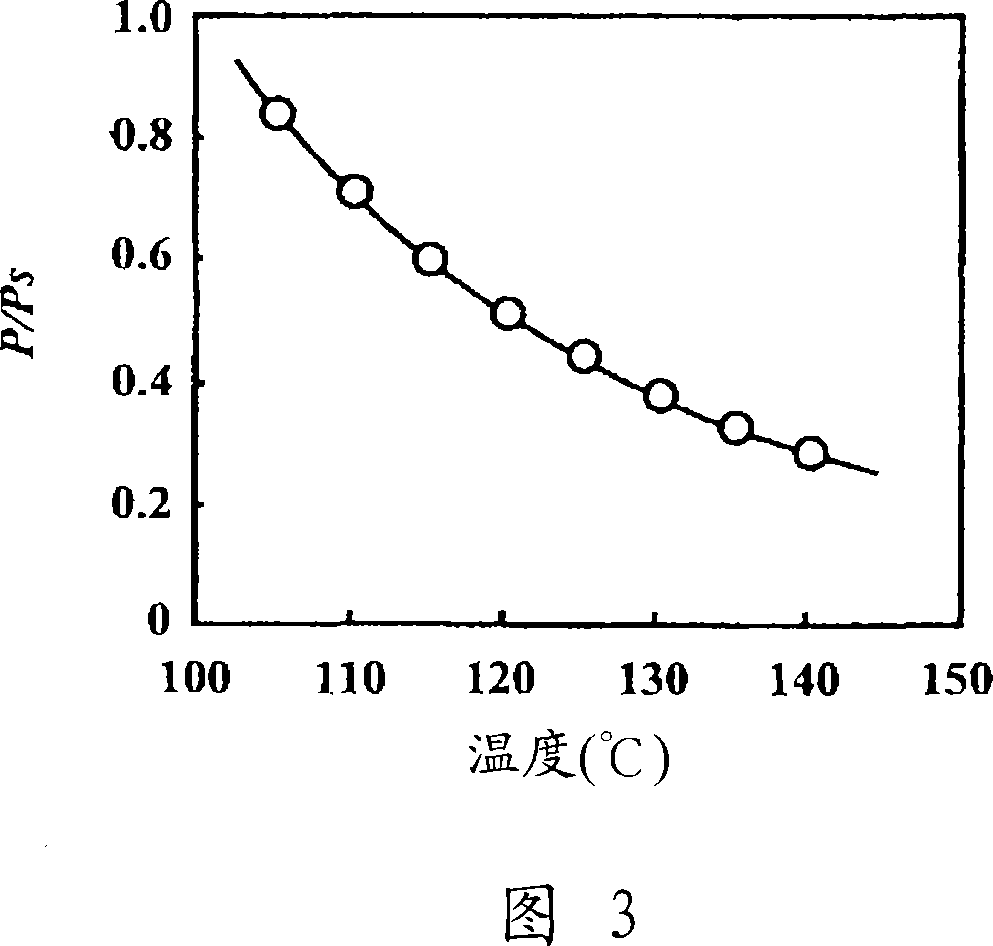

[0086] First, LTA-type zeolite powder is made into granules. Then, the pH 4 aqueous solution of acetic acid is boiled under normal pressure, the steam and zeolite particles are heated to 130°C which does not cause capillary condensation, and the generated steam is brought into contact with the zeolite particles. Next, the LTA-type zeolite particles were treated at this temperature for 20 hours as Example 1. In addition, the LTA-type zeolite particles were treated for 100 hours in the same manner as Example 2.

[0087] The sample treated under the above conditions was taken out from the sample tube and dried overnight at room temperature, and then the particles were powdered. The crystal structure of the particles was analyzed by XRD (X-ray Diffraction). In addition, the crystal structure of the LTA-type zeolite powder before the above treatment was also analyzed by XRD. In FIG. 6 , the analysis results are shown with the angle on the horizontal axis and the intensity on the...

Embodiment 3

[0092] A zeolite membrane densely formed of LTA-type zeolite crystals is formed on a tubular alumina porous support. Specifically, this zeolite membrane was produced as described below.

[0093] First, fine particles of type A zeolite (100 nm in particle diameter) were added to water and stirred to prepare a slurry having a concentration of 0.5% by mass. A tubular porous support made of α-alumina (average pore diameter 1.3 μm, outer diameter 10 mm, inner diameter 6 mm, length 13 cm) was immersed in the slurry for 3 minutes, and then lifted at a speed of about 0.2 cm / s. Then, after drying in a 25 degreeC thermostat for 2 hours, it dried in a 70 degreeC thermostat for 16 hours. Then mix sodium silicate, aluminum hydroxide and distilled water so that the molar ratio of each component is SiO 2 / Al 2 o 3 = 2, Na 2 O / SiO 2 = 1, H 2 O / Na 2 O=75, make a hydrothermal reaction solution. The porous support provided with the seed layer was immersed in the reaction solution, and k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com