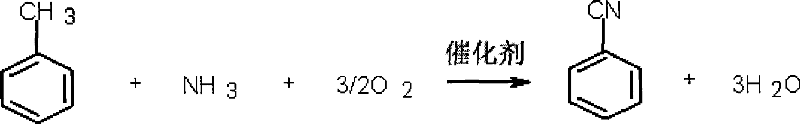

Production method of benzonitrile

A production method and technology of benzonitrile, applied in the direction of hydrocarbon ammoxidation preparation, organic chemistry, etc., can solve problems affecting fluidization quality, channeling, throttling, poor mechanical strength, etc., and achieve simple operation of the production process, increase Product yield, effect of improving fluidization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Heat the toluene and liquid ammonia materials separately, and vaporize them. The preheating temperature is 195°C. 3 / h flow and enter the fluidized bed reactor at a pressure of 0.032MPa, with a flow rate of 500m 3 / h hot air phase contact, react under the action of fine particle catalyst BN98 (produced by Shanghai Petrochemical Research Institute), the reaction temperature is 410-420 ° C, the catalyst load is 45 grams of toluene / liter catalyst hour, continuous Production. The temperature of the product gas flowing out from the top outlet of the fluidized bed reactor can reach about 300°C, and the air can be preheated through heat exchange to save energy. Then it is cooled by spraying water in the trapping tower, and condensed into benzonitrile and water in liquid phase. The uncondensed gas in the capture tower enters the absorption tower and continues to be cooled with spray water. The upper layer of benzonitrile enters the separator through overflow, and the produc...

Embodiment 2

[0032] Heat toluene and liquefied ammonia separately to vaporize. The preheating temperature is 190°C. 3 / h flow and enter the fluidized bed reactor at a pressure of 0.04MPa, with a flow rate of 400m 3 / h hot air phase contact, react under the effect of fine particle catalyst BN98 (produced by Shanghai Petrochemical Research Institute), the reaction temperature is 410-420 ℃, the catalyst load is 42 grams of toluene / liter catalyst hour, carry out continuous Production. All the other steps are the same as in Example 1. Crude benzonitrile was obtained with a content of 96.53%, and pure benzonitrile was obtained through vacuum distillation with a content of 99.8%. The water content of benzonitrile was 0.02%, and the yield was 73.12%.

Embodiment 3

[0034]Heat toluene and liquefied ammonia separately to vaporize. The preheating temperature is 200°C. 3 / h flow and enter the fluidized bed reactor at a pressure of 0.05MPa, with a flow rate of 300m 3 / h hot air phase contact, react under the action of fine particle catalyst BN98 (produced by Shanghai Petrochemical Research Institute), the reaction temperature is 410-420 ° C, the catalyst load is 37 grams of toluene / liter catalyst hour, continuous Production. The remaining steps were the same as in Example 1 to obtain crude benzonitrile with a content of 97.82%, and vacuum distillation to obtain pure benzonitrile with a content of 99.7%, a water content of 0.02%, and a yield of 64.23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com