Heat resistant adhesive film and electromagnetic steel sheet with said heat resistant adhesive film, iron core using said electromagnetic steel sheet, and process for manufacturing the same

A technology of insulating coating and electrical steel plate, applied in the direction of bonding method, metal material coating process, coating, etc., can solve the problems of abrasive die hole, deterioration of bonding strength, hard coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Aqueous suspensions mixed with glass frits having a softening point of 450° C. and having various particle sizes were prepared, the aqueous suspensions each containing 20% by mass (based on the mass of 100% total solids) composed of acrylic resin:epoxy resin:phenol resin= A resin with a composition of 10:4:3 (mass%). The resin / glass frit mixing ratio in each solution containing glass frit was adjusted to 200%. Each coating solution was applied to a thickness of 0.5 mm on a finish annealed non-oriented electrical steel sheet without an insulating coating to a coating weight of 6 g / m on each side using a roll coater 2 . The board was dried at 150°C and cooled. The coating thickness was 10 μm on each side. A test piece having a length of 10 cm in the rolling direction and a length of 3 cm in the direction perpendicular to the rolling direction was cut from each sample. Alternatively, let two such specimens overlap a length of 1 cm on the short side and an overlapping...

Embodiment 2

[0096] Prepared with B 2 o 3 =25% by mass, SiO 2 = 65% by mass, Na 2 O=10% by mass composition and a linear thermal expansion coefficient of 30°C-300°C is 40×10 -7 (℃ -1 ) glass frit mixed aqueous suspension (example of the invention) and the same but with 2 o 3 =50% by mass, SiO 2 = 25% by mass, K 2 O=25% by mass composition and a linear thermal expansion coefficient of 30°C-300°C of 170×10 -7 (℃ -1 ) glass frit mixed suspension (comparative example), the aqueous suspensions each comprise 20% by mass (based on the mass of 100% total solids) by acrylic resin: epoxy resin: phenolic resin = 11: 3: 4 (mass %) composed of resins. The glass frit used in each example had an average particle size of 10 μm. The resin / glass frit mixing ratio in the glass frit-containing solution was adjusted to 100% in each case.

[0097] Each coating solution was applied to a thickness of 0.5 mm on a finish annealed non-oriented electrical steel sheet having an insulating coating of magnes...

Embodiment 3

[0102] The following four types of coating solutions were prepared.

[0103] Coating Solution A

[0104] To 100 parts by mass of water, 40 parts by mass of an acryl-modified epoxy resin emulsion containing 20% by mass of a latent curing agent and 5 parts by mass of methyl ethyl ketone were mixed. The resin obtained by coating and baking this coating solution had a glass transition temperature of 104°C and softened at 120°C or higher.

[0105] Coating Solution B

[0106] Into 100 parts by mass of water, 40 parts by mass of acrylic resin emulsion, 40 parts by mass of epoxy resin emulsion and 4 parts by mass of amino epoxy curing agent were mixed. The resin obtained by coating and baking this coating solution softens at 150°C or higher.

[0107] Coating Solution C

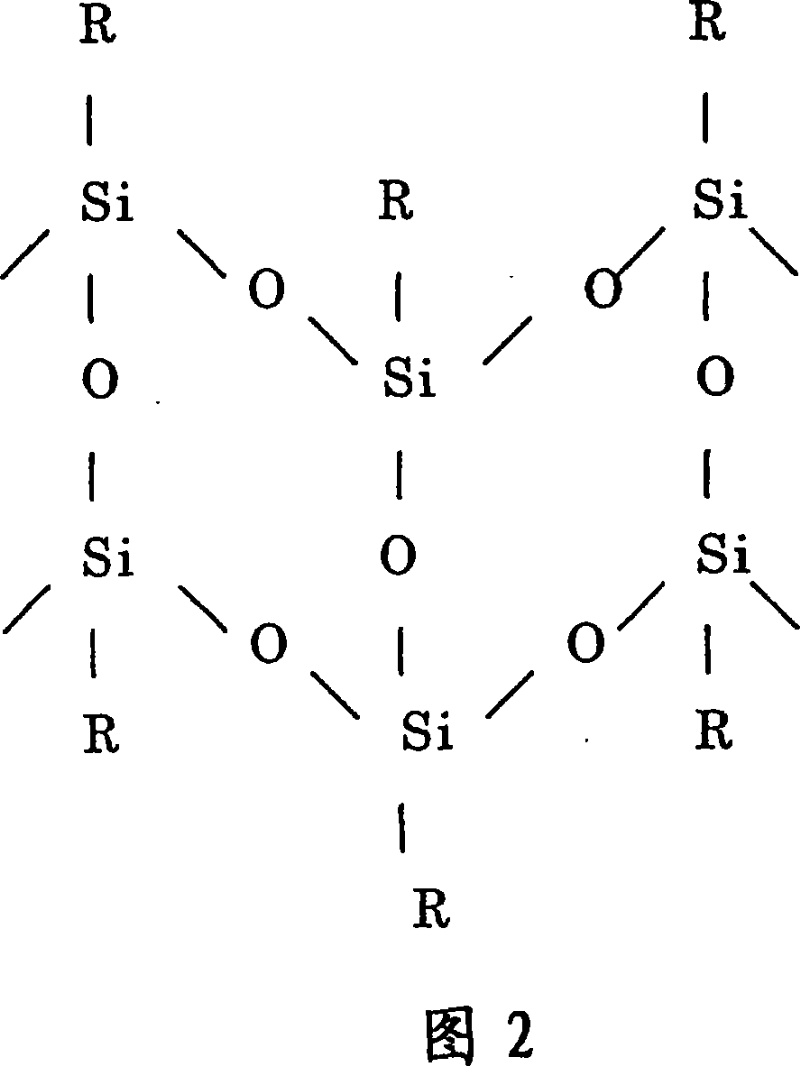

[0108]To a mixed solution of 178 g of methyltriethoxysilane and 138 g of ethanol, 35.3 g of water and 1.04 g of an aqueous solution of 35% hydrochloric acid were added dropwise for hydrolysis. The hydrolyzed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com