Method for producing edible nanoscale high-pressure spraying dried bear barm protein powder

A technology of brewer's yeast and protein powder, which is applied in the direction of protein composition of yeast, protein food processing, protein food ingredients, etc., can solve the problems of industrialization development and utilization restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

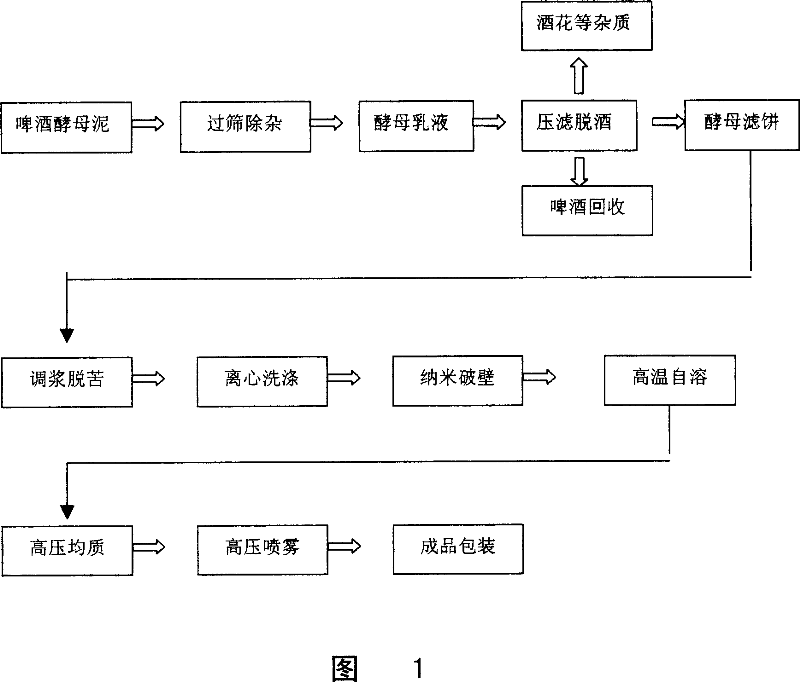

Image

Examples

Embodiment 1

[0089] Preparation of brewer's yeast protein powder No.1

[0090] 1500kg of fresh beer yeast stock solution with 86% water content and material temperature of 7.8°C is sieved twice through 100 mesh and 120 mesh, and then the valuable beer is recovered after the use of a plate and frame filter press. After beating, add food grade NaHCO according to the proportion of 0.5% of the raw material weight 3 , Stir evenly and adjust the pH of the solution to 7.0, fully react for 45 minutes, then dilute with 1:2 water and wash twice at high speed using a yeast centrifuge to obtain a higher purity (concentration 12%) yeast milk. Use a nano collider to break the wall by physical high pressure, pressure: 85Mpa, break the wall once. After the wall is broken, the yeast solution enters the reaction vessel at a constant temperature of 85°C for 1 hour and sterilizes. The material liquid is homogenized by pump and high pressure, and then emulsified by high pressure spray (180°C) and instantaneous (8 ...

Embodiment 2

[0093] Preparation of beer yeast protein powder No.2

[0094] 1500kg of fresh beer yeast stock solution with 86% water content and material temperature of 7.8°C is sieved twice through 100 mesh and 120 mesh, and then the valuable beer is recovered after the use of a plate and frame filter press. After beating, add food grade NaHCO3 at a ratio of 0.5% by weight of the raw materials, stir evenly and adjust the pH of the solution to 7.0, fully react for 45 minutes, then dilute with 1:2 water and wash 2 times with a yeast centrifuge cycle at high speed to obtain High-purity yeast milk, adjust the concentration of the material to 13%, the physical wall breaking pressure is 90Mpa, the wall breaking is repeated twice, the wall breaking temperature is 45℃, and the temperature is rapidly raised to 95℃ within 30 minutes. High temperature autolysis for 1 hour And sterilize. The material liquid is homogenized by pump and high-pressure, and then emulsified by high-pressure spray (240°C) and in...

Embodiment 3

[0097] Preparation of beer yeast protein powder No.3

[0098] 1500kg of fresh beer yeast stock solution with 86% water content and material temperature of 7.8°C is sieved twice through 100 mesh and 120 mesh, and then the valuable beer is recovered after the use of a plate and frame filter press. After beating, add food grade NaHCO according to the proportion of 0.5% of the raw material weight 3 , Stir evenly and adjust the pH of the solution to 7.0, fully react for 45 minutes, and then dilute 1:2 with water and wash twice at high speed using a yeast centrifuge to obtain a higher purity yeast milk, and adjust the yeast concentration to 5%) and then use a nano collider to break the wall by physical high pressure, pressure: 75Mpa, break the wall once, the yeast solution enters the reaction vessel after breaking the wall, and is sterilized at a constant temperature of 85°C for 0.5 hours. The material liquid is homogenized by pump and high pressure, and then emulsified by high pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com