Method for removing polyacrylamide and other organic matters in oilfield exploration water and electrochemical reactor

A technology of polyacrylamide and reactor, applied in the direction of electrochemical water/sewage treatment, water pollutants, chemical instruments and methods, etc., can solve environmental pollution and other problems, achieve good treatment effect, easy to scale up, and increase mass transfer rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

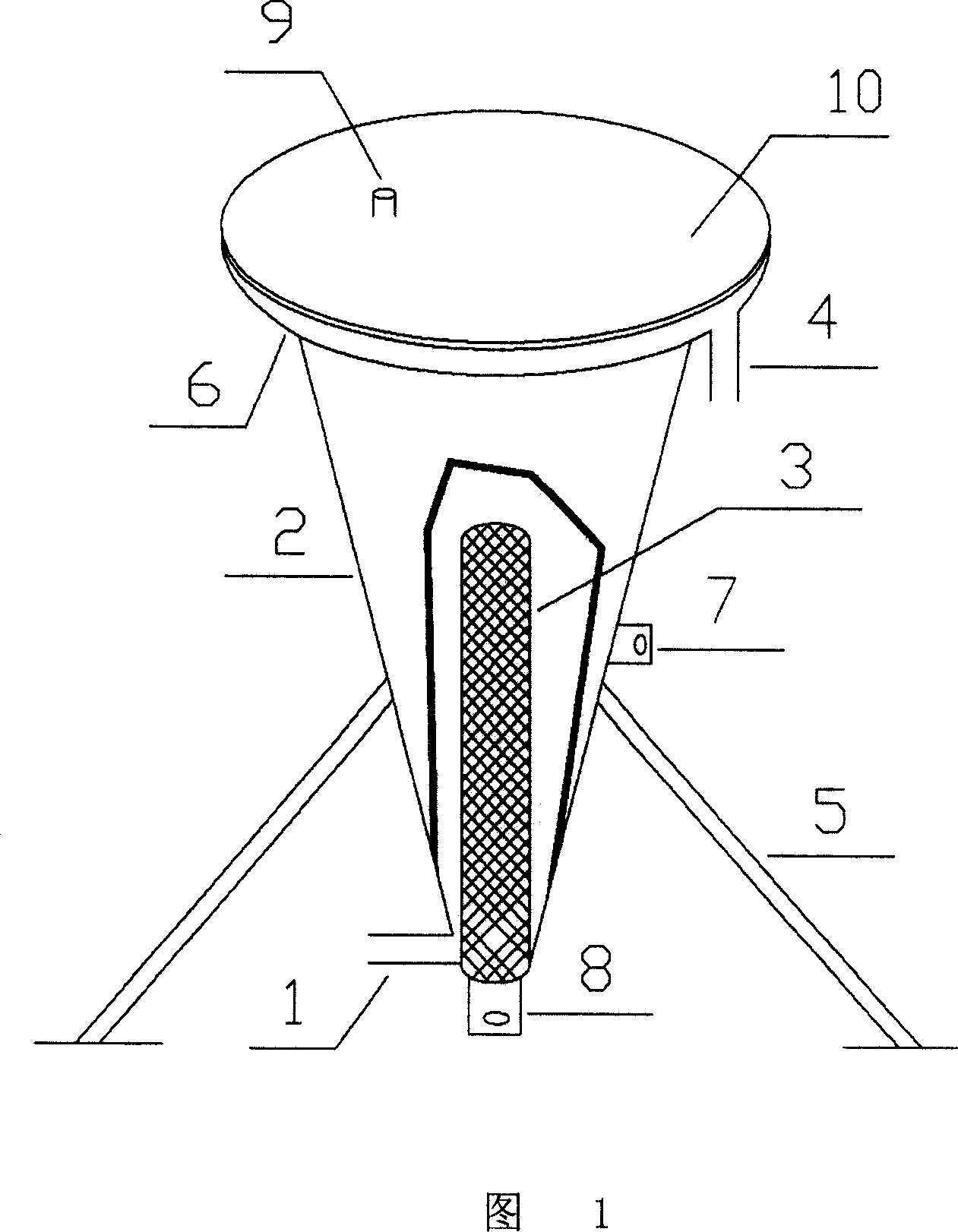

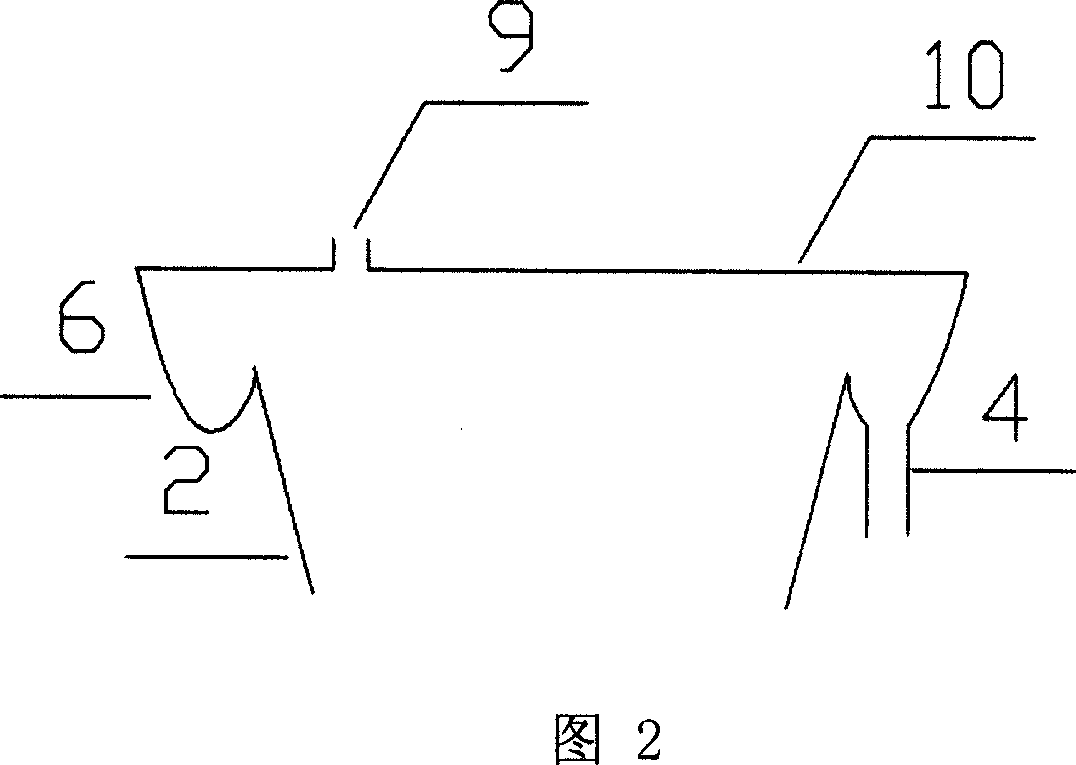

[0035] Example 1: Under normal temperature and pressure, the reactor is operated intermittently, using polymer-containing produced water collected from Daqing Oilfield, the volume of the water sample is 300ml, filtered, and sulfuric acid is added to adjust the pH value to 3.0, the applied DC voltage is 6V, and the current density 150A / m 2 , the electrode effective area is 12cm 2 , using a titanium-based electrode coated with ruthenium-iridium oxide layer as the anode, the cathode as stainless steel, no diaphragm is set between the cathode and the anode, and the pole distance is 1.5cm. Samples were taken at regular intervals, and various parameters of the water samples were measured after filtration. The experimental data measured are shown in Table 1.

[0036] parameters

as it is

15min

30min

45min

HPAM(mg / L)

COD (mg / L)

406.42

717.93

98.5

305.68

39.75

105.8

17.25

70.85

[0037] ...

Embodiment 2

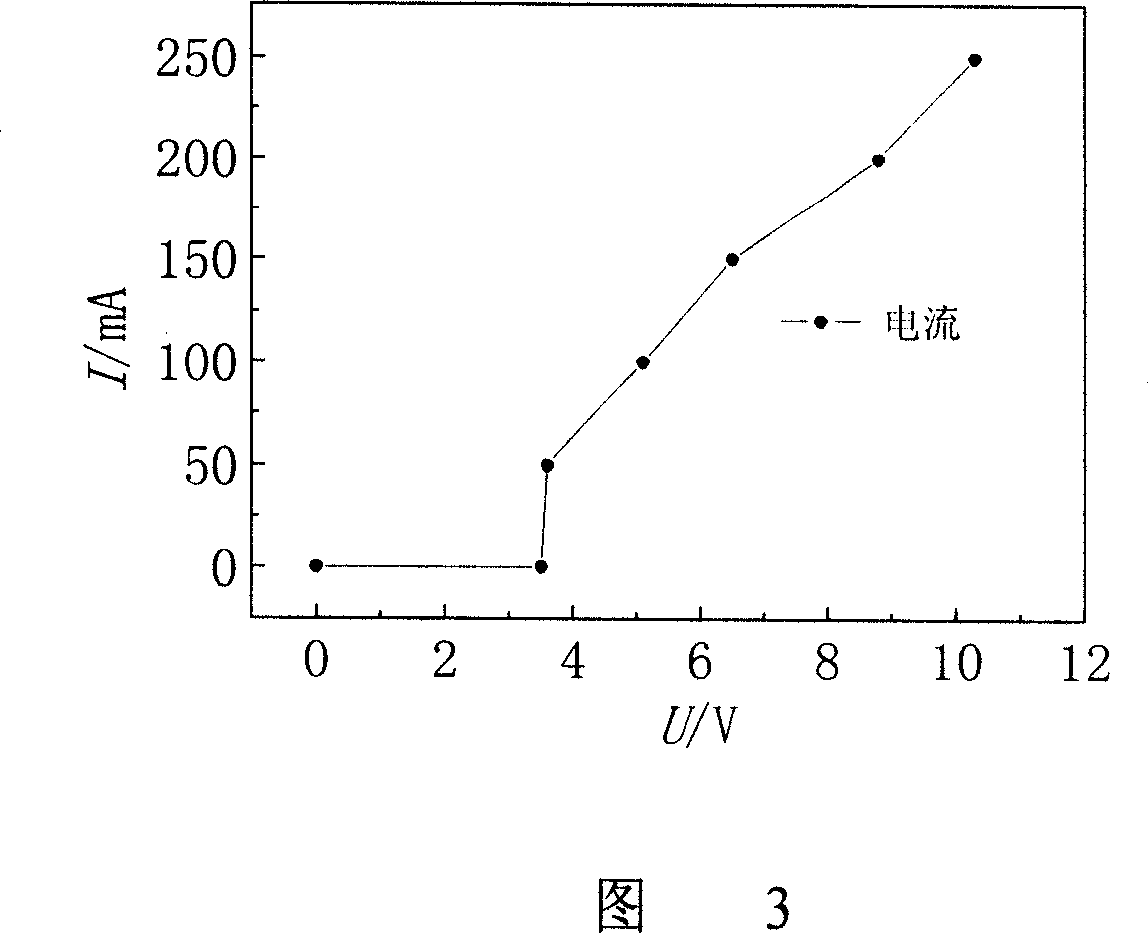

[0039] Example 2: The applied DC voltage is 3.6V, and the current density is 50A / m 2 , other operating conditions are the same as in Example 1, COD=150.45mg / L during 45min treatment, COD removal rate is 79.04%, HPAM=65.83mg / L, HPAM removal rate is 83.8%.

Embodiment 3

[0040] Example 3: Under normal temperature and pressure, the reactor operates continuously, using poly-containing produced water collected from Daqing Oilfield, the volume of the reaction zone is 300ml, the hydraulic retention time is 30min, the water sample is filtered, and the pH value is adjusted to 3.0 by adding sulfuric acid , the applied DC voltage is 6V, and the current density is 150A / m 2 , the electrode effective area is 12cm 2 , using a titanium-based electrode coated with ruthenium-iridium oxide layer as the anode, the cathode as stainless steel, no diaphragm is set between the cathode and the anode, and the pole distance is 1.5cm. Samples are taken at regular intervals, and various parameters of the water samples are measured after filtration. COD=92.43mg / L was measured at 90min treatment, COD removal rate was 87.13%, HPAM=40.25mg / L, HPAM removal rate was 90.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com