Method for high efficiency separating and purifying 1-deacetyl Baccatins III (10-DABIII)

A technology of separation, purification and deacetylation, which is applied in the direction of organic chemistry, can solve problems such as yield loss, large solvent consumption, and reduced solvency, so as to improve the separation degree and separation peak shape, increase yield and purity, and demand Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

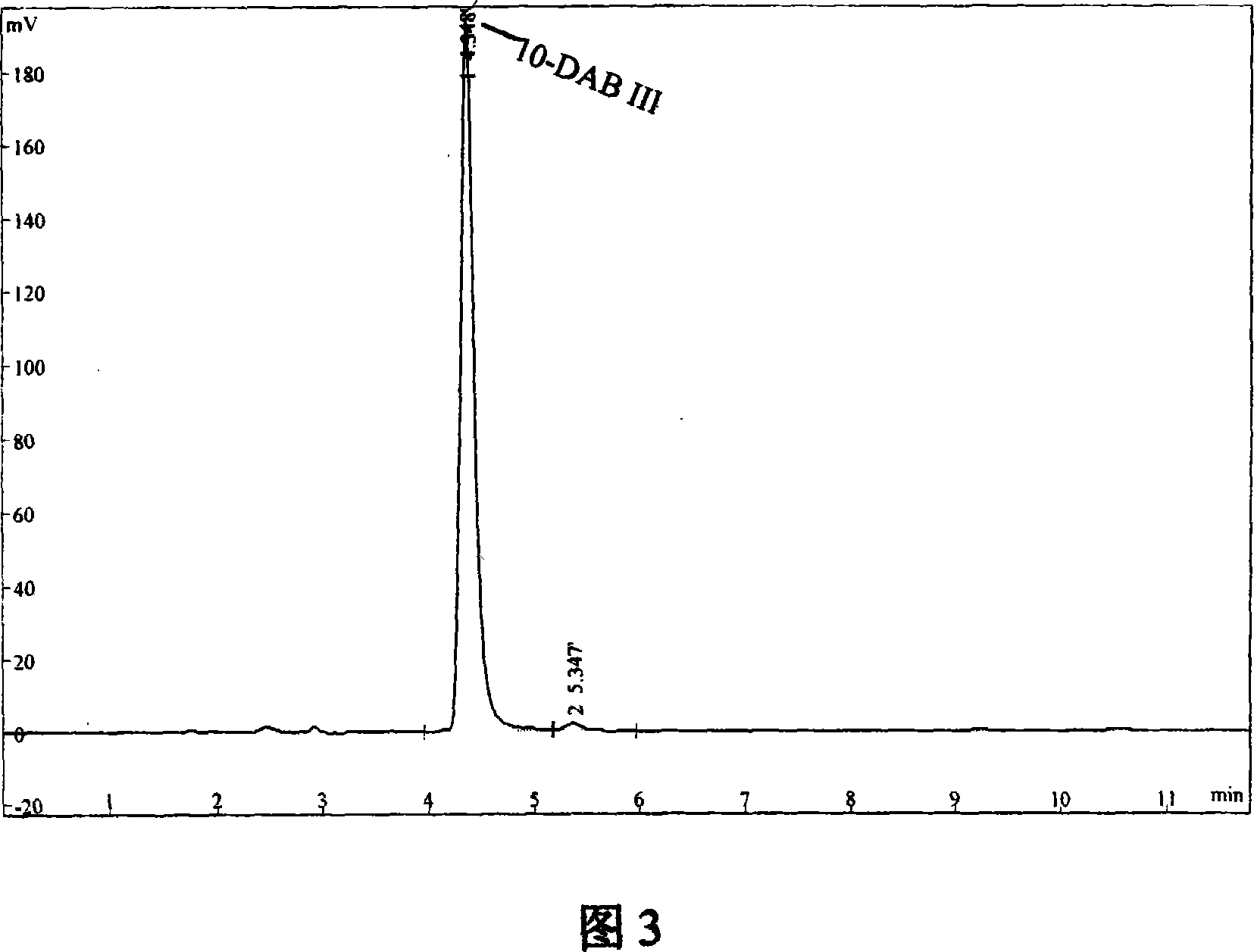

[0031] Embodiment 1, the raw material of semi-finished product 10-deacetylbaccatin III is low content, and the method for sample dissolution and separation and purification has tetrahydrofuran

[0032] Take by weighing 100 grams of 10-DAB III raw material powder with a content of 23%, prepare a chromatographic column with a dynamic axial compression liquid phase of 100mm, the packing is spherical silica gel of 20-45um, and the aperture is 70A, and a total of 1650 grams of packing ( 10-DABIII: the weight ratio of packing is about 1.40%), the separation chromatographic column is 40cm long, and the mobile phase is 22:77:1=tetrahydrofuran:n-hexane:methanol (volume ratio).

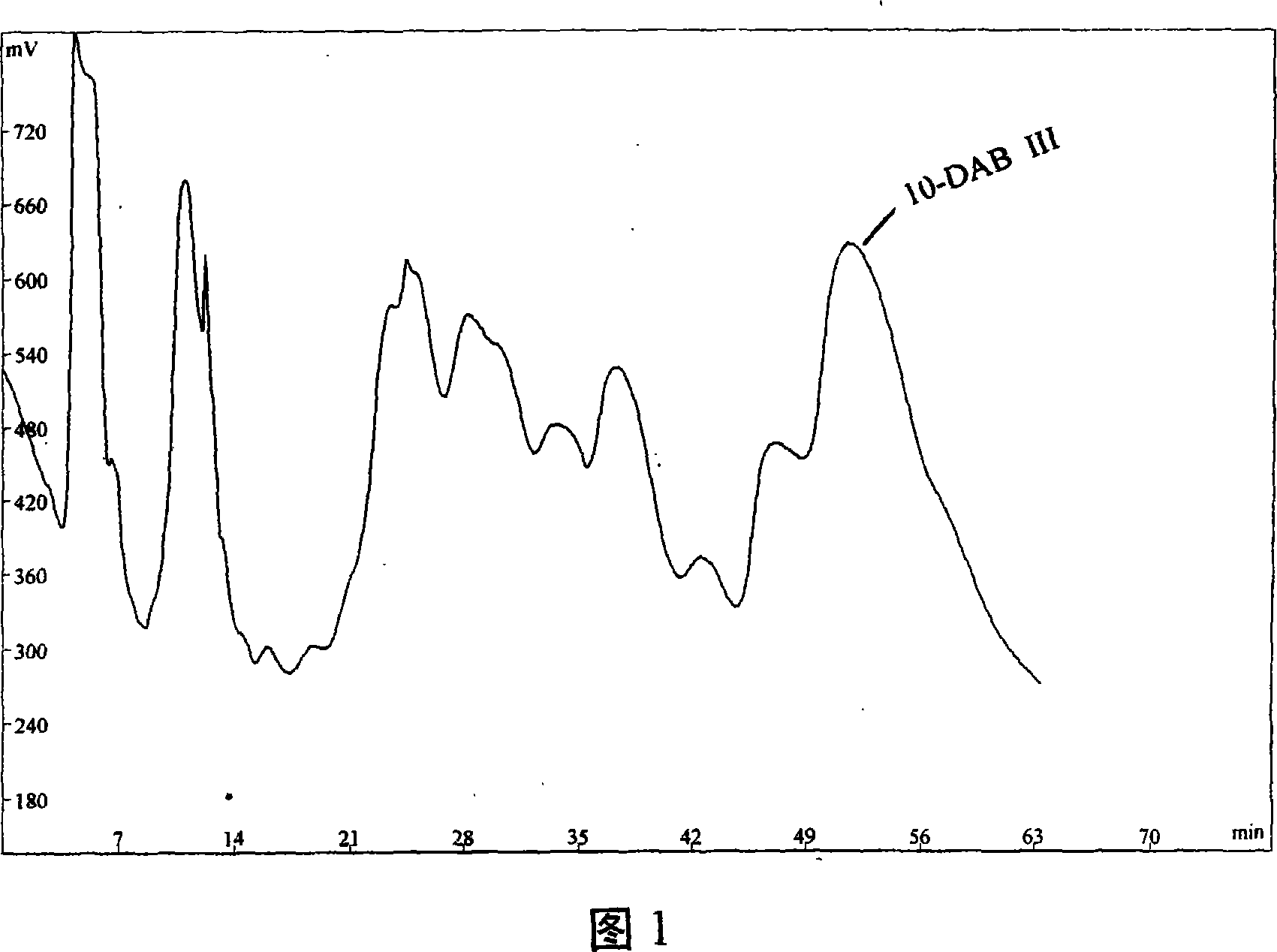

[0033] Weigh 100 grams of 10-DAB III raw material powder with a content of 23%, use tetrahydrofuran at 50° C. to promote dissolution by ultrasonic waves, filter, and inject 50 grams of samples into the compressed liquid phase preparative chromatographic column each time. A mixed solution of tetrahydrofuran, n-h...

Embodiment 2

[0035] Example 2, the raw material of semi-finished product 10-deacetylbaccatin III has a high content, and the method for sample dissolution and separation and purification has tetrahydrofuran

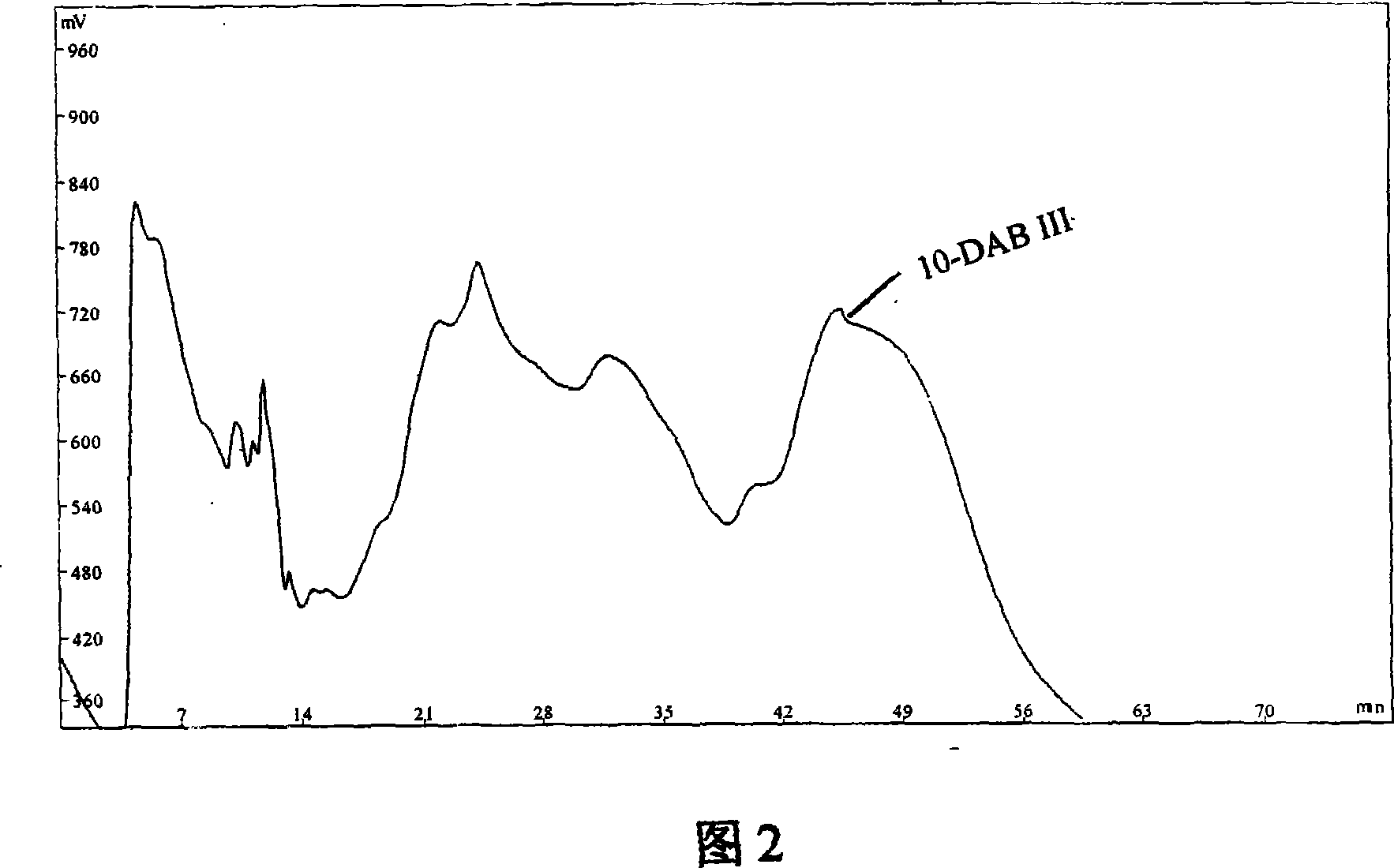

[0036] Weigh 60 grams of 10-DAB III powder (content is 53%) of the raw material, prepare a chromatographic column with a dynamic axial compression liquid phase of 100mm, the packing is spherical silica gel of 20-45um, the aperture is 70A, and a total of 1650 grams are filled Packing (10-DAB III: the weight ratio of packing is about 1.92%), the length of separation chromatographic column is 35cm, and the mobile phase is 26:73:1=tetrahydrofuran:n-hexane:methanol (volume ratio).

[0037] Weigh 60 grams of 10-DAB III raw material powder with a content of 53%, promote dissolution with tetrahydrofuran at 55° C. by ultrasonic waves, filter, and inject 30 grams each time. A mixed solution of tetrahydrofuran, n-hexane and methanol is used as the mobile phase, and the separation time is 55 minu...

Embodiment 3

[0040] This embodiment is the same as the steps of embodiment 2, only THF:n-hexane:methanol (volume ratio)=30:68:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com