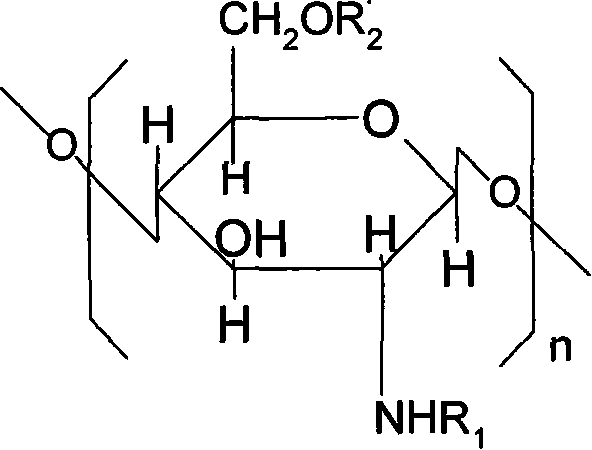

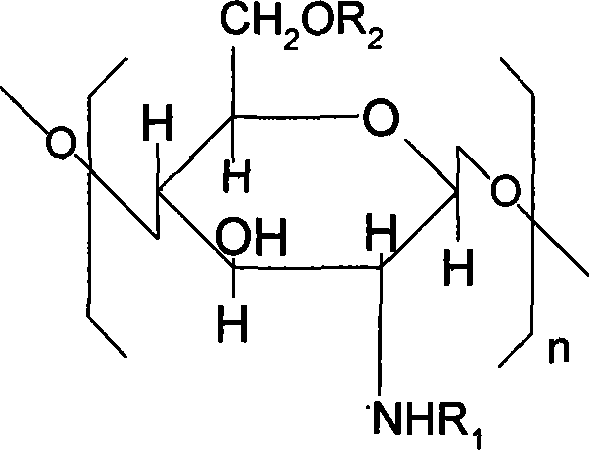

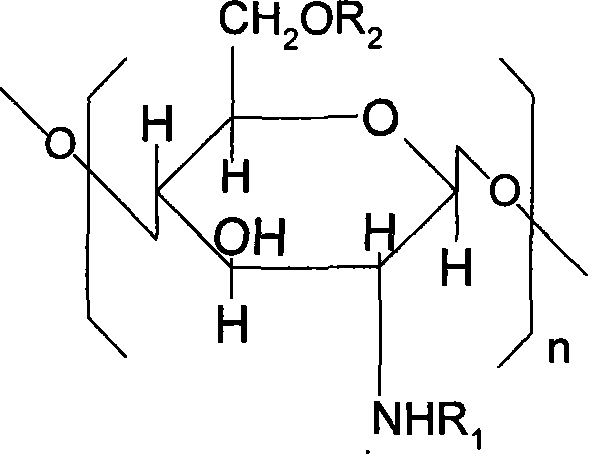

Anti hemorrhagic healing traumatic material of chitosan based fiber in water-solubility, preparation method and application

A technology of water-soluble chitosan and chitosan fiber, which is applied in the field of medical materials, can solve the problems of long degradation time of carboxymethyl chitosan fiber, inflammatory response, and inapplicability, so as to promote wound healing and good compatibility , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The preparation of carboxymethyl chitosan fiber non-woven fabric: take chitosan fiber non-woven fabric 12g, place in the wide mouth reagent bottle of 500ml, add the KOH aqueous solution 200g of 45% (weight percent concentration, the same below) , stirring to immerse the chitosan fiber non-woven fabric completely in the lye, place it at -20° C. for 24 hours, and alkalize it to obtain an alkalized chitosan fiber non-woven fabric. Take out this alkalized chitosan nonwoven fabric, put into the jar of 500ml, add 55% acetone aqueous solution 180g as reaction medium, add the ethanol solution 85g of the monochloroacetic acid of 50% under shaking condition as reaction reagent, room temperature Under reaction 9hr, obtain carboxymethyl chitosan fiber non-woven fabric. Take out the carboxymethyl chitosan fiber non-woven fabric, fully wash it to neutrality with 60% acetone aqueous solution as washing liquid, dehydrate with anhydrous acetone, squeeze or centrifugally dry, remove exce...

Embodiment 2

[0014] The preparation of carboxymethyl chitosan fiber: take chitosan fiber 5g, place in the wide-mouth reagent bottle of 500ml, add 30% NaOH aqueous solution 160g, stir to make chitosan fiber all immerse in the lye, under room temperature Place it for 48 hours to alkalize to obtain alkalized chitosan fiber. Take out this alkalized chitosan fiber, put into the jar of 500ml, add methanol 160g as reaction medium, add the methanol solution 46g of 50% monochloroacetic acid under shaking condition as reaction reagent, react 8hr under the room temperature, obtain carboxylate Methyl chitosan fiber. Take out the carboxymethyl chitosan fiber, use methanol as washing liquid to fully wash to neutral, squeeze or centrifugally dry, remove excess liquid, and then put it in a container containing P 2 o 5 Vacuum-dried in a special vacuum desiccator, and evaporated the residual organic solvent in the dried product at 50°C to obtain carboxymethyl chitosan fibers with a carboxymethyl substitut...

Embodiment 3

[0017] Preparation of carboxymethyl chitosan fiber knitted fabric: take 10 g of chitosan fiber knitted fabric, place it in a 500 ml wide-mouth reagent bottle, add 200 g of 40% NaOH aqueous solution, stir to make the chitosan fiber knitted fabric fully immersed In the lye, place it at 0-4°C for 48 hours to alkalize to obtain alkalized chitosan fiber knitted fabric. Take out the alkalized knitted fabric, put it into a 500ml wide-mouth bottle, add 135g of 90% ethanol aqueous solution and 50g of dimethyl sulfoxide as the reaction medium, and add 70g of 50% ethanol solution of monochloroacetic acid under shaking conditions as the reaction reagent , and reacted at room temperature for 10 hours to obtain carboxymethyl chitosan fiber knitted fabric. Take out the carboxymethyl chitosan knitted fabric, use 75% ethanol aqueous solution as washing liquid to fully wash to neutral, dehydrate with absolute ethanol, squeeze or centrifugally dry, remove excess liquid, then put it in a containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com