Synthesizing method and equipment for fabricating light ground substance by using farming and forestry biolobic material

A biomass, light substrate technology, applied in the field of comprehensive treatment of agricultural and forestry biomass, can solve problems such as damage to the root growth of seedlings, danger, unsuitability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

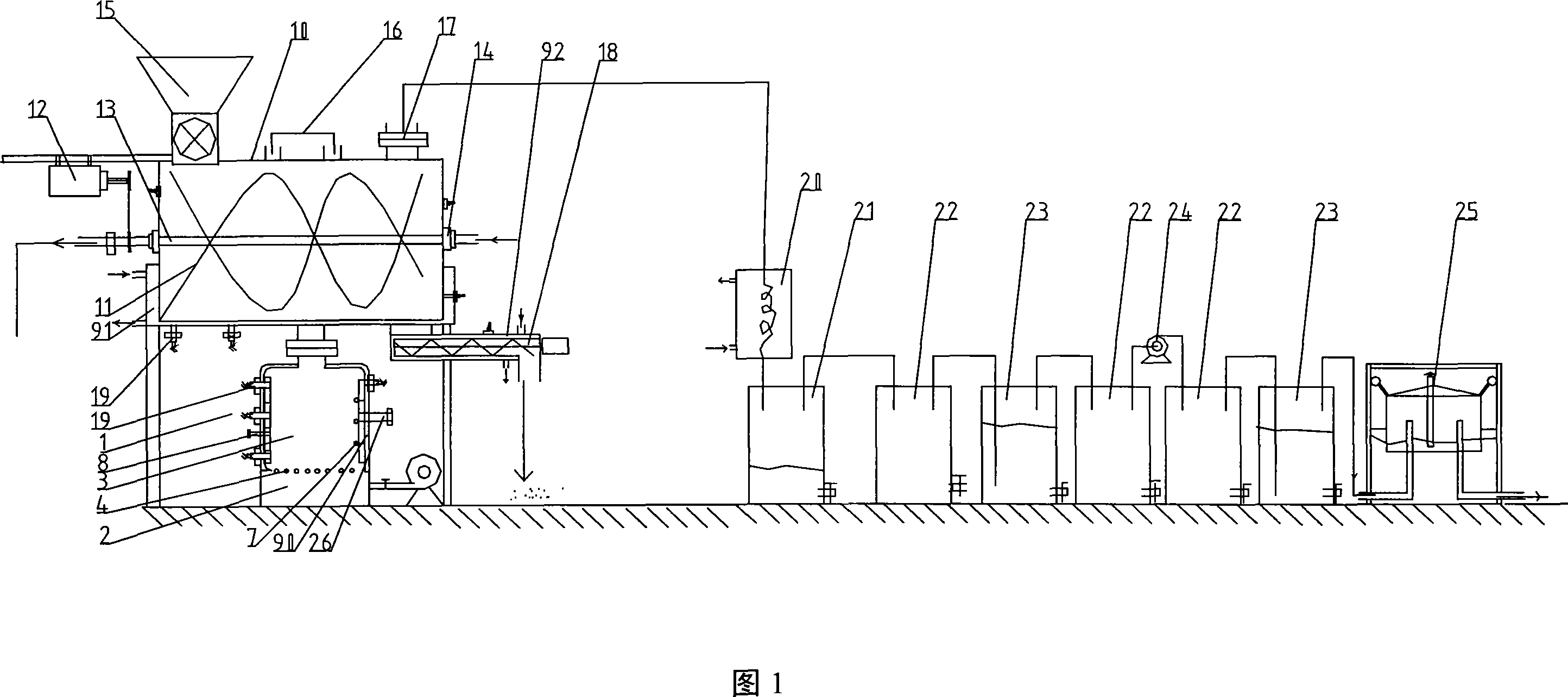

[0056] The device in this example includes: a combustion system, a cracking system, an organic liquid collection system, and a combustible gas collection system.

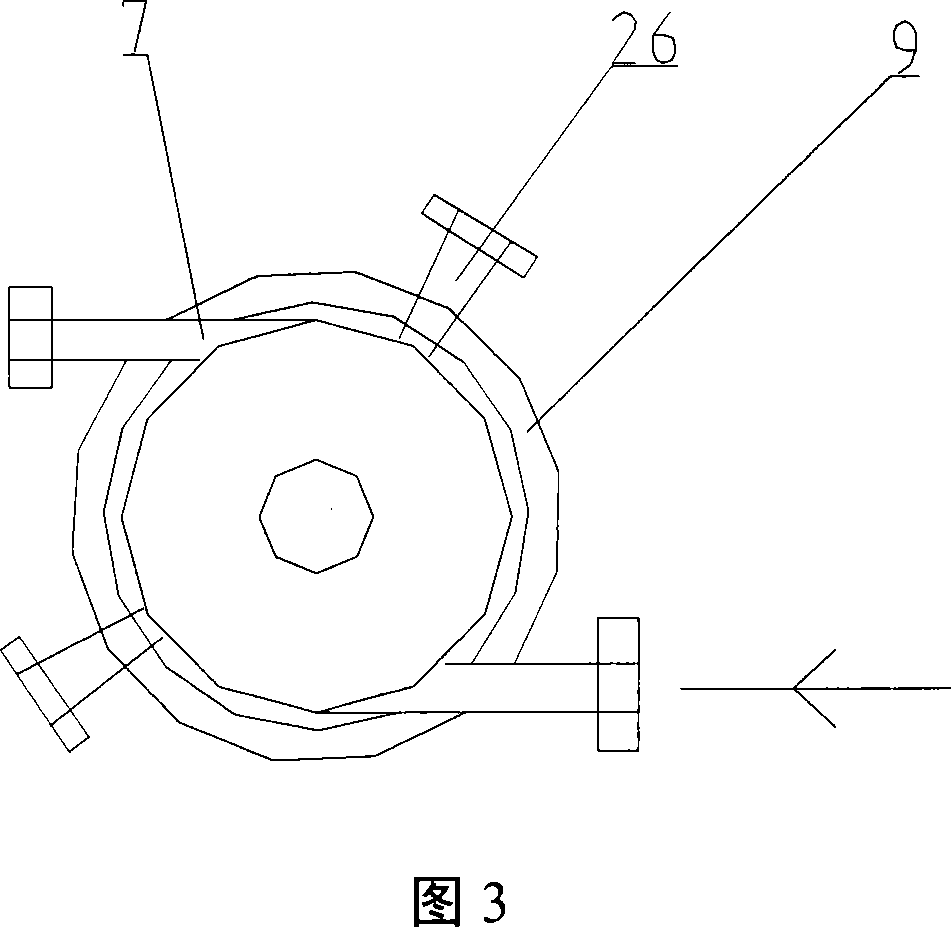

[0057] The combustion system includes a combustion furnace 1. The combustion furnace 1 includes an ash chamber 2 and a furnace 3. The ash chamber 2 is located at the bottom of the combustion furnace 1. A movable grate 4 is provided between the ash chamber 2 and the furnace 3. The side wall of the ash chamber 2 is provided with a fan air inlet 5, and the air inlet 5 is connected with the blower 6, and 4 pairs of tangential air inlet pipes 7 are installed in the furnace 3, and the side wall of the furnace 3 is provided with 2 temperature sensors 19 and 2 The openable observation window can be used to observe and transfer the materials in the furnace. Four tubes 8 facing different directions in the furnace 3 are also installed on the furnace wall. The outer ends of the tubes 8 are closed and can be opened if necessary,...

Embodiment 2

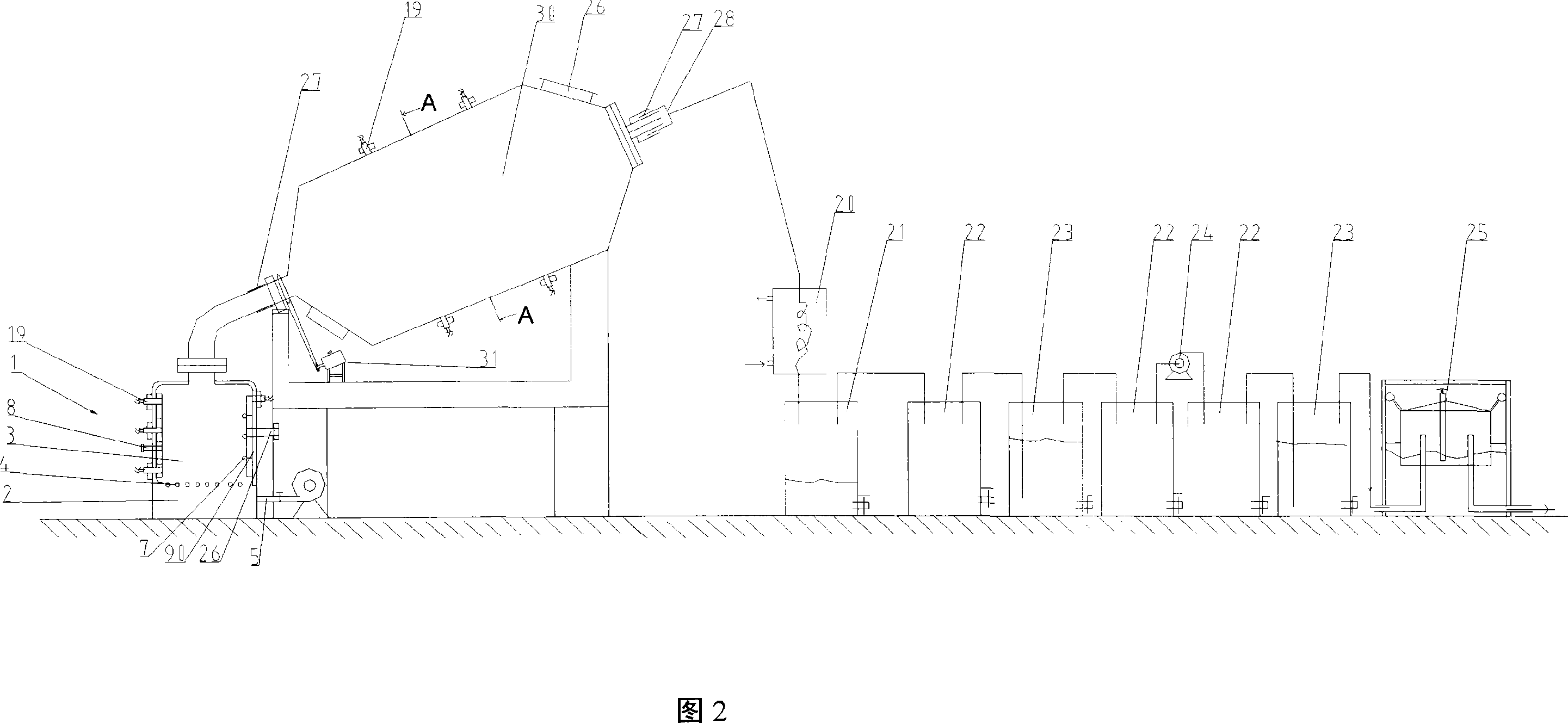

[0062] The basic structure in this example is the same as that of Example 1, except that the cracking furnace is the difference. The cracking furnace 30 in this example adopts a rotating structure, and its axial upper end is provided with a water seal cover 27 and a flange gas outlet 28, and its axial lower end is connected with the combustion furnace 1, and its outer wall is provided with at least one temperature sensor 19, There is a steel helix 29 inside it. When the furnace body rotates forward, the material inside can be turned over to achieve the effect of uniform heating. When it is reversed, the material can be poured out from the top. When it is necessary to add materials, the top inlet flange can be opened to add materials, and the drum is tilted and rotated normally.

[0063] The pyrolysis furnaces of Example 1 and Example 2 are interchangeable, and they are suitable for different materials. One is suitable for the smaller solid biomass agriculture and forestry such...

Embodiment 3

[0065] Take sawdust as an example below to illustrate the working method of the device of the present invention

[0066] ① Put the sawdust containing wood blocks and chips into the insufficient rotary drum cracking furnace through the rotary feeder, and the volume of the material is 2 / 3 of the volume of the device.

[0067] ②Put dry firewood into combustion gasifier

[0068] (2) Temperature control process of combustion gasification and incomplete cracking

[0069] Light the firewood in the combustion furnace, turn on the blower to adjust the air volume to fully oxidize and burn the firewood. When the dry wood in the furnace needs to be replenished after burning less, the blast volume should be appropriately reduced. During the rotation and stirring process of the materials in the cracking system, a small part of the materials will fall into the combustion furnace. Since the inner wall of the furnace hall has a thicker refractory material, the furnace hall maintains a higher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com