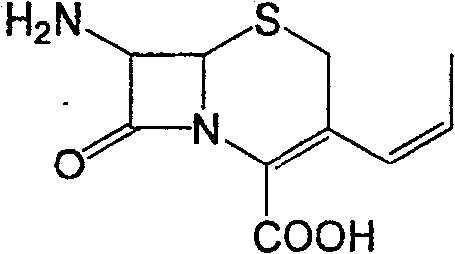

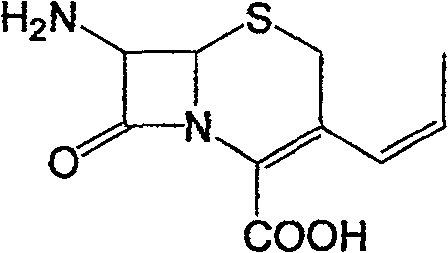

Method of preparing cefprozil parent nucleus 7-amino-3-propenylcephalosporanic acid

A technology of propenyl cephalosporanic acid and cefprozil mother nucleus, which is applied in the direction of organic chemistry, can solve the problems of unstable quality, high cost, and low yield, and achieve the effect of low price, low cost, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

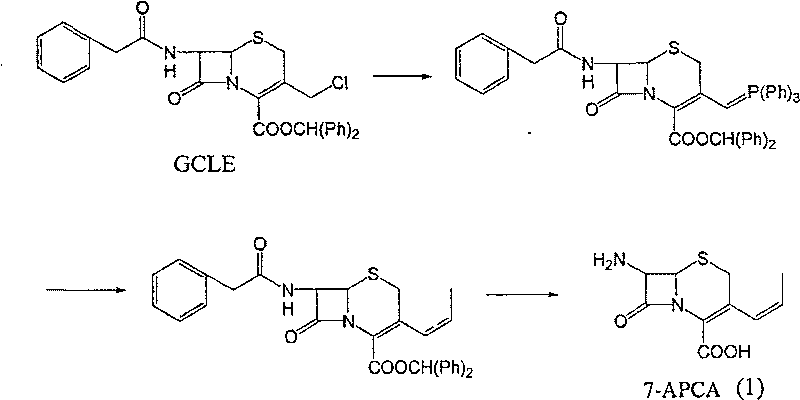

Method used

Image

Examples

Embodiment 1

[0029] Step 1: At room temperature, add 12g of 7-ACA, 100ml of dichloromethane, 10g of hexamethyldisilazane (HMDS), 1ml of trimethylchlorosilane into a dry reaction flask, and raise the temperature to 40-55°C under nitrogen protection , reflux for 7-8 hours, and when it is detected that there is almost no ammonia escape in the reflux tail gas, the reflux is stopped and the temperature is lowered to 0-5° C. to obtain a silylated solution of 7-ACA. 13.5 g of triphenylphosphine was added to the reaction liquid, and 11.5 g of iodotrimethylsilane was added in about 10 minutes, and the temperature should not be higher than 5°C. After the addition is complete, keep the reaction at 5-10°C for 3-5 hours, take a sample to detect that the 7-ACA residue is less than 0.5g / L (HPLC), after the reaction is completed, cool down to -5-0°C to obtain a mixture of compound (3) .

[0030] Step 2 Add 87ml of DMF to the mixed solution of compound (3) obtained in step 1, control the temperature at 0-...

Embodiment 2

[0033] Step 1. At room temperature, add 12g of 7-ACA and 100ml of dichloromethane to the dry reaction flask, cool down to 0-5°C, add 13.5g of triphenylphosphine, and add 33g of iodotrimethylsilane within about 10 minutes. The temperature shall not be higher than 5°C. After the addition is complete, keep the reaction at 5-10°C for 3-5 hours, take a sample to detect that the 7-ACA residue is less than 0.5g / L (HPLC), after the reaction is completed, cool down to -5-0°C to obtain a mixture of compound (3) .

[0034] Subsequent operation is the same as embodiment one, and the result is the same.

Embodiment 3

[0036] Step 1, step 2 are the same as embodiment 1.

[0037] Step 3: Vacuum distill the mixture of compound (4) obtained in step 2 to remove dichloromethane. The distillation temperature is controlled below 50°C. After the distillation is complete, cool down to room temperature, add 5g of activated carbon, stir for 30 minutes, and filter. Add 400ml of water to the filtrate, heat up to 35-40°C, keep stirring for 30 minutes, cool down to 0-5°C, stir for 1 hour, filter, and wash with 50ml of water and 100ml of acetone. Vacuum drying at 35°C for 7-8 hours gave 10.2 g of 7-APCA with a purity of 95.5% (HPLC cis / trans = 92.5 / 7.5). Yield 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com