Method of preparing 3C-SiC nano particles by chemical corrosion method

A nanoparticle and chemical corrosion technology, which is applied in the field of preparation of 3C-SiC nanoparticles, can solve the problems of inability to prepare single-structure phase nanoparticles, expensive SiC multi-chips, difficulties in preparation and purchase, and achieve blue light emission and preparation. Simple method, easy to obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

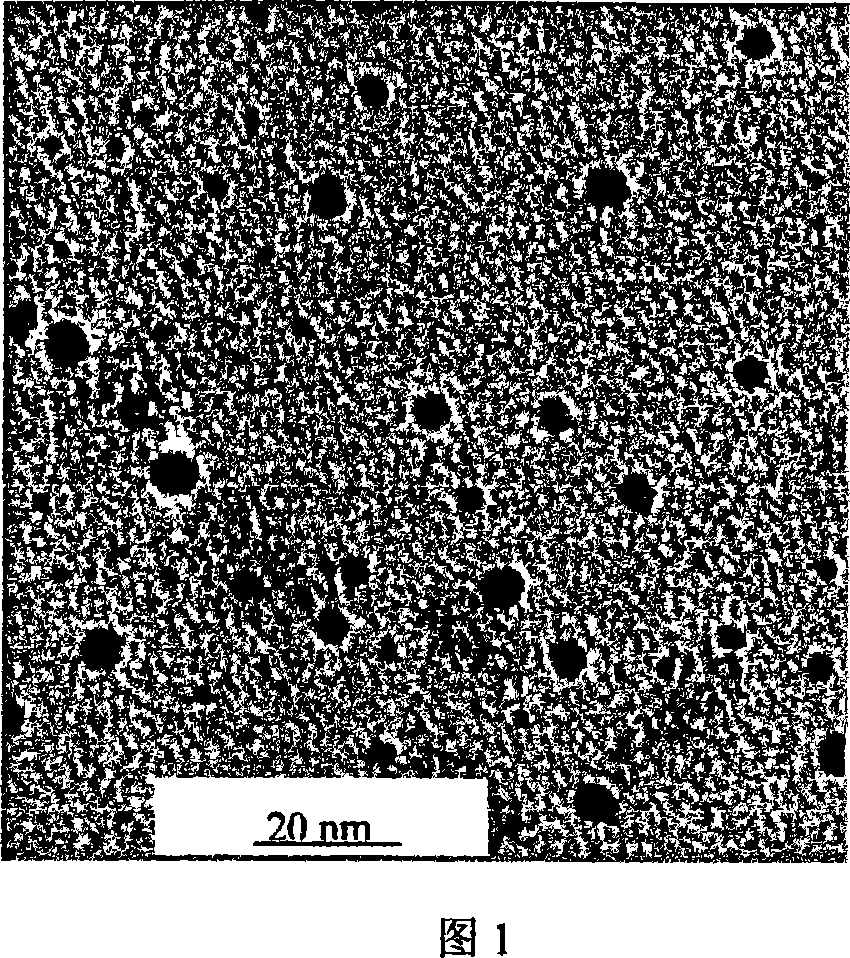

[0011] The acid used for common chemical etching is 40% hydrofluoric acid and 65% nitric acid, with a volume ratio of 3:1. During preparation, weigh 10 g of 3C-SiC powder, add it to 100 ml of the above mixed acid, and heat in a constant temperature bath at 100° C. for 1 hour. After cooling, centrifuge the reacted acid solution and powder together in a high-speed centrifuge, pour off the upper layer of acid solution, take out the lower layer of powder, and dry it in an oven at about 80°C. Add deionized water or absolute ethanol to the dried powder, ultrasonically cavitate for 30 minutes, let stand for several hours or centrifuge, and take the supernatant. The deionized water or absolute ethanol clear solution contains 3C-SiC nanoparticles with a size smaller than 8nm. The average size of such nanoparticles is about 3.8 nm.

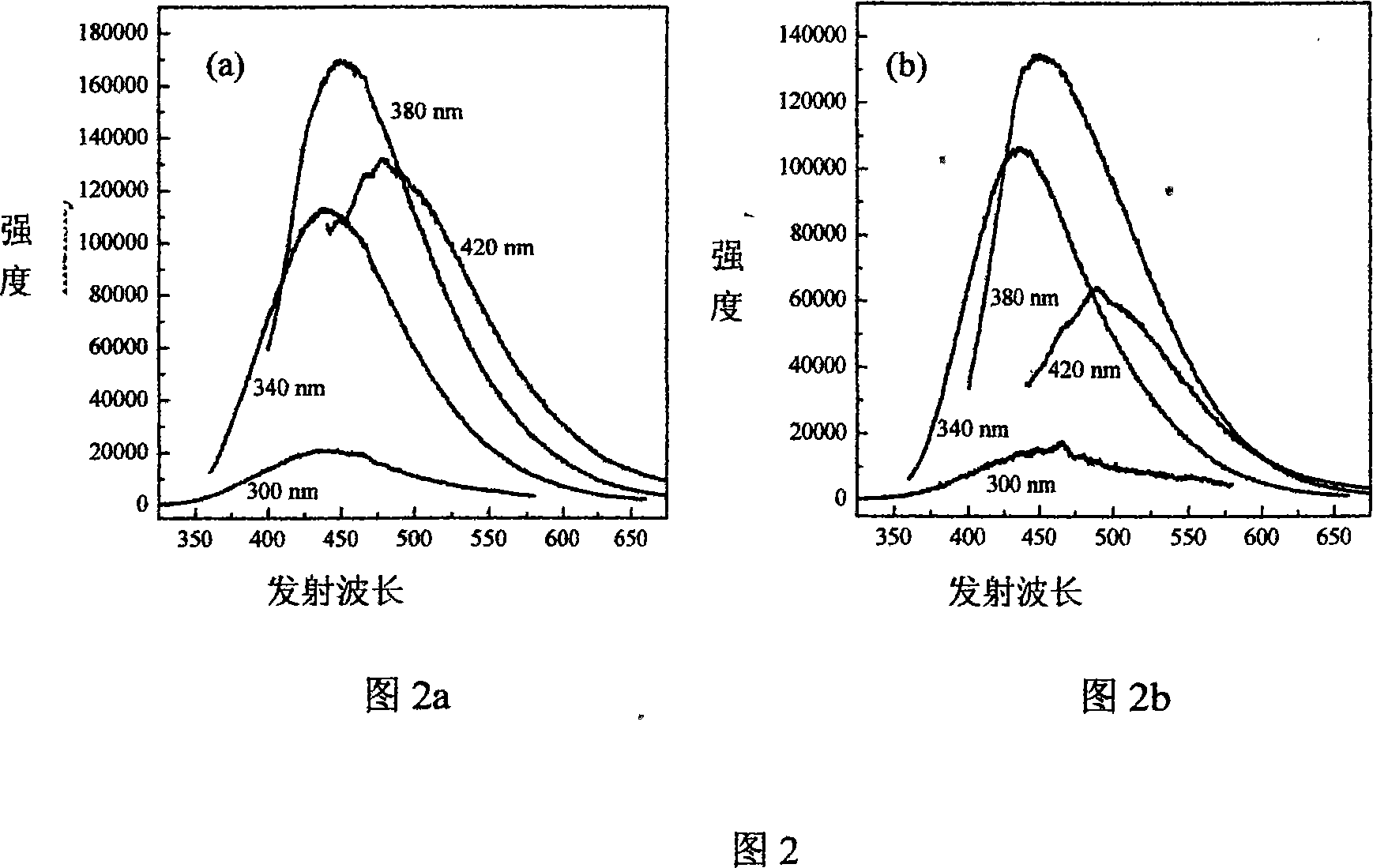

[0012] High resolution electron micrographs demonstrate that the size of the nanoparticles is less than 8.0 nm. The photoluminescence spectrum shows tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com